Method for measuring rheological properties of sensitive medicine material

A technology of sensitive chemicals and rheological properties, applied in the direction of DC flow characteristics measurement, etc., can solve the problems of difficult rheological performance testing of sensitive chemicals, the influence of pressure detection accuracy, threats to personal and property safety, etc., and achieves a small error. , Guarantee the effect of accurate reliability and strong safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

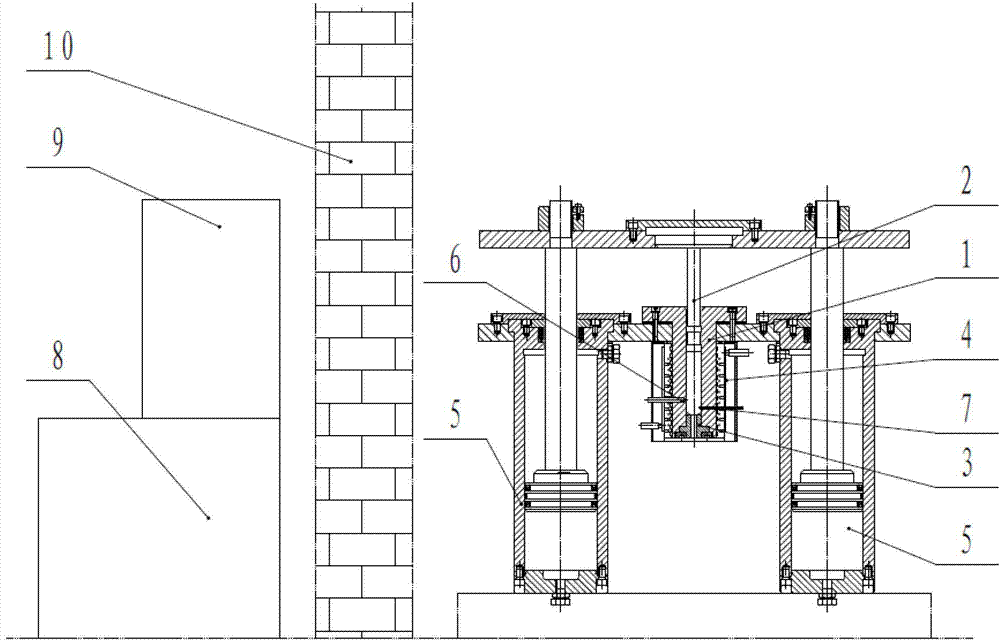

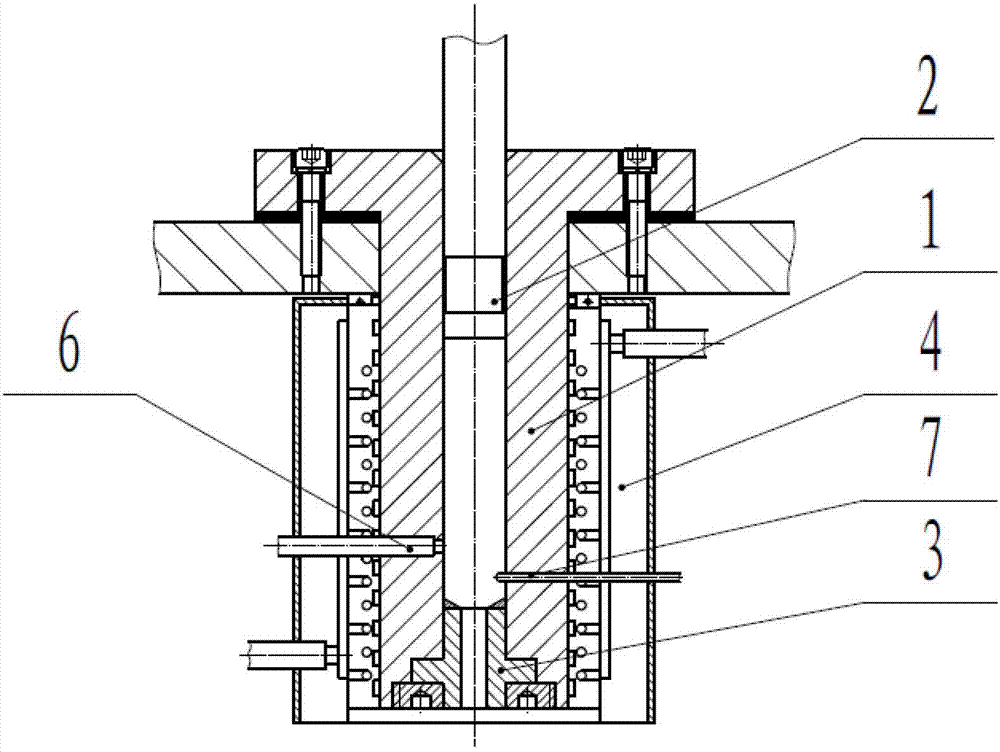

[0027]A method and device for measuring the rheological properties of sensitive medicinal materials. The device is composed of a testing system, a data acquisition system 8 and a remote control system 9. The testing system includes a barrel 1, a plunger 2, a capillary 3, and a heating system 4. Transmission system 5, pressure sensor 6, temperature sensor 7, displacement sensor. The plunger 2 is set on the upper part of the barrel 1, which can go in and out of the barrel 1 and move up and down linearly driven by the transmission system 5; the capillary 3 is set on the lower end of the barrel 1 and can be replaced. The diameter of the pipe hole has 1.5mm, 2mm and 4mm, and the length-to-diameter ratio of the capillary 3 has 5, 10, 15 and 20. The present embodiment adopts two kinds of capillaries 3 whose pipe diameter is 4mm and the length-to-diameter ratio is 5 and 10; The heating system 4 is arranged around the barrel and the capillary, and is heated by an oil bath; the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com