Portable photovoltaic subassembly power testing instrument and testing method thereof

A photovoltaic module and power testing technology, which is applied in the monitoring of photovoltaic systems, single semiconductor device testing, photovoltaic power generation, etc., can solve the evaluation method that cannot guarantee the power error of photovoltaic modules, the volt-ampere characteristics of photovoltaic modules are nonlinear, and it is difficult to establish power To achieve the effect of improving the efficiency of assembly and connection, simplifying the testing procedure, and saving working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

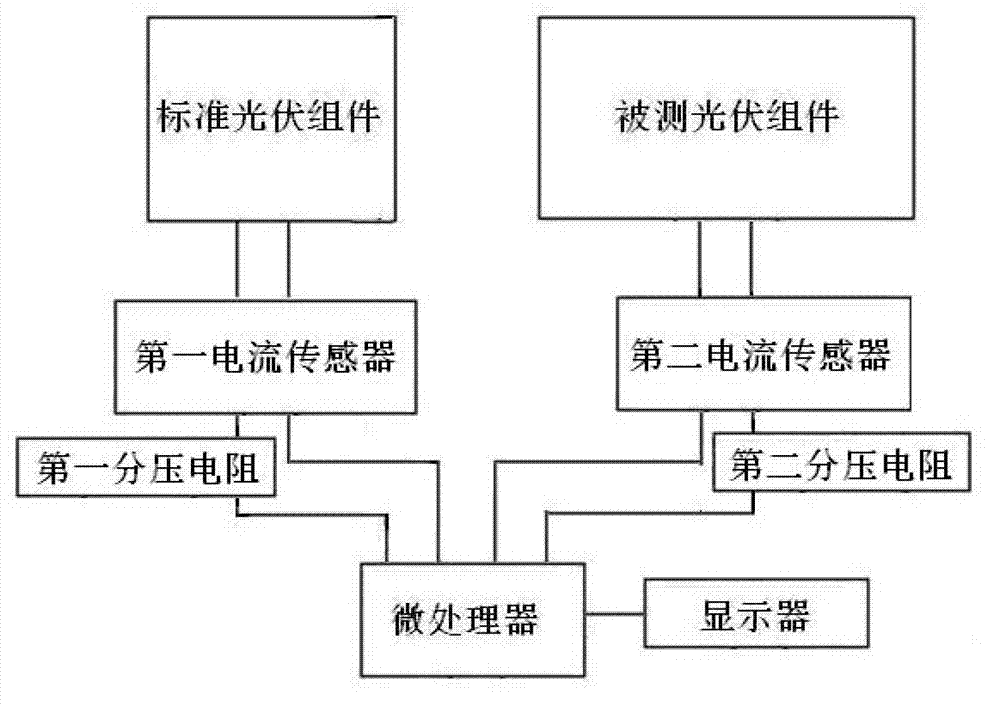

[0028] refer to figure 1 As shown, the portable photovoltaic module power testing instrument includes a standard photovoltaic module, a port, a microprocessor, a first and a second voltage dividing resistor, a first and a second current sensor and a display. The standard photovoltaic module, the first current sensor, the first voltage dividing resistor, and the microprocessor are connected in series, the port, the second current sensor, the second voltage dividing resistor, and the microprocessor are connected in series, and the microprocessor is connected to the display. The power testing instrument is connected to the photovoltaic module under test from the port; when the power is turned on, the pulse is triggered or the switch is started, and the two current sensors start working at the same time, collecting the short-circuit current of the standard photovoltaic module and the short-circuit current of the photovoltaic module under test respectively. The short-circuit curren...

Embodiment 2

[0031] Portable photovoltaic module power test instrument, including standard photovoltaic module, port, microprocessor, display and two current sensors. The standard photovoltaic module, the first current sensor, and the microprocessor are connected in series, the port, the second current sensor, and the microprocessor are connected in series in turn, and the microprocessor is connected to the display. The power testing instrument is connected to the photovoltaic module under test from the port; when the power is turned on, the two current sensors start at the same time to collect the short-circuit current of the standard photovoltaic module and the short-circuit current of the photovoltaic module under test respectively. The short-circuit current data input of the standard PV module and the PV module under test contains "Standard power of the PV module under test = standard power of the standard PV module * open circuit voltage of the PV module under test * short-circuit curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com