Automatic programming and functional test all-in-one machine for light-radio frequency transceiving module

A technology for radio frequency transceiver modules and functional testing, applied in transmission monitoring/testing/fault measurement systems, multi-channel programming devices, etc., can solve problems such as difficulty in ensuring accuracy and consistency, system cable loss, and low equipment utilization. , to achieve the effect of ensuring accuracy and consistency, convenient plug-in connection operation, and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings.

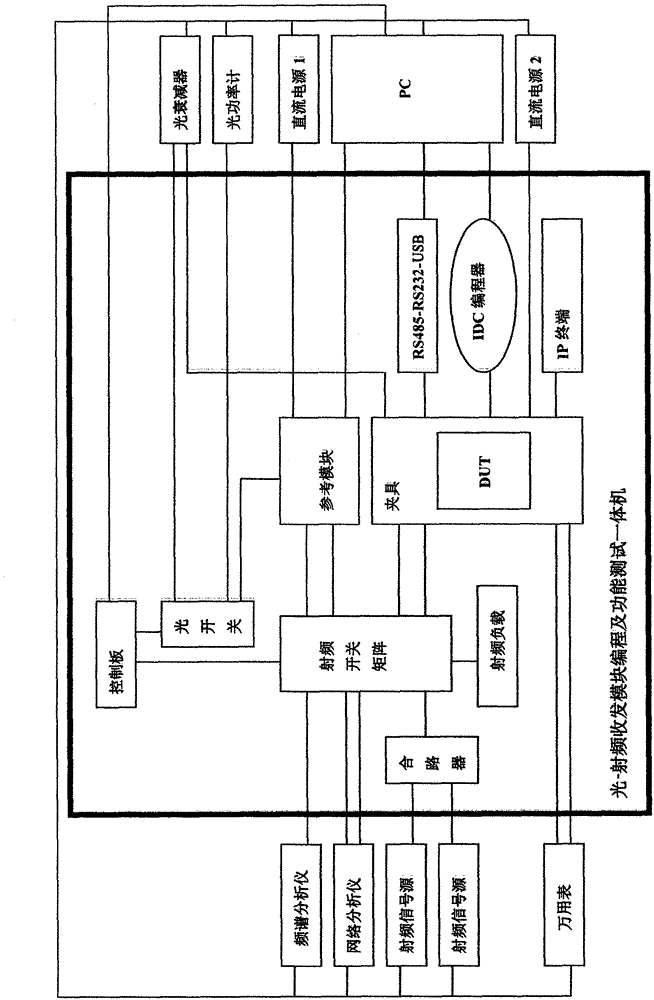

[0027] The connections between the various components are as image 3 As shown, the TTL signal output ports of the control board are respectively connected to the TTL control ports of the RF matrix switch and the optical switch. The RF matrix switch is respectively connected to the circuit breaker, the RF load, the reference module and the fixture, and the RF cable is connected to the external spectrum analyzer, Network analyzer and signal generator, the optical switch has a fiber jumper connected to the optical power meter, optical attenuation meter and reference module, the optical port of the fixture is connected to the optical power attenuation meter with a fiber jumper, and its RF port is connected to the RF matrix switch Connected, the RS232-RS485 module, IDC programmer and IP terminal all have interfaces connected to the fixture. There is a special wire on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com