Method for manufacturing an aluminosilicate glass substrate for hard disks

A technology of aluminosilicate glass and a manufacturing method, which is applied in the directions of manufacturing tools, manufacturing base layers, and record carrier manufacturing, etc., can solve the problems of collision between magnetic heads and disk surfaces, and achieve the effect of reducing surface undulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] [Preparation Method of Polishing Liquid Composition]

[0066] The polishing composition can be prepared by mixing components by a known method. From an economical point of view, polishing liquid compositions are usually produced as concentrates, which are often diluted at the point of use. The polishing liquid composition can also be used as it is, and if it is a concentrated liquid, it can be used after being diluted. In the case of diluting the concentrate, the dilution ratio is not particularly limited, and can be appropriately determined according to the concentration of each component in the concentrate (content of grinding material, etc.), grinding conditions, and the like.

[0067] The pH of the polishing liquid composition can be adjusted to a predetermined pH after the mixing of the ingredients, or the pH of the polishing liquid composition can be adjusted to a desired value by mixing the ingredients. The pH of the ingredients were adjusted individually befor...

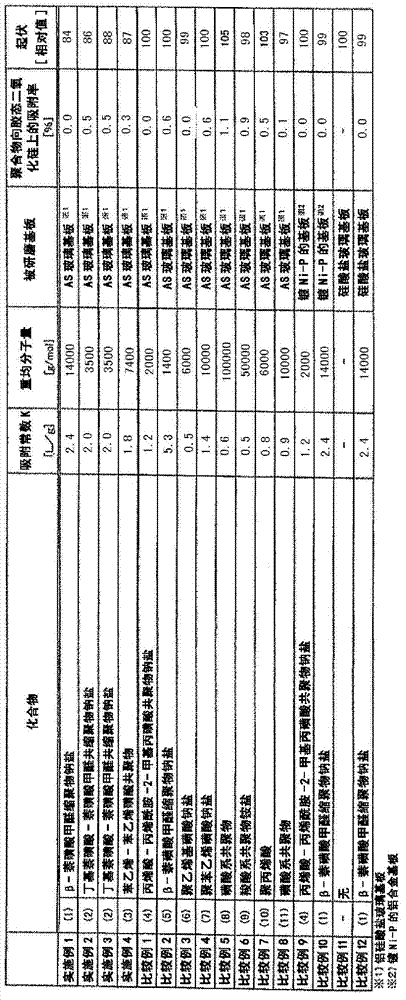

Embodiment 1~4 and comparative example 1~12

[0089] 1. Preparation of ground substrate

[0090] Table 2 shows details of the substrates to be polished. Wa (arithmetic mean fluctuation) of a medium wavelength (160-500 micrometers) is the value measured with New View 5032 (made by Zygo Corporation).

[0091] (1) Aluminosilicate glass substrate

[0092] As a substrate to be polished, an aluminosilicate glass substrate previously roughly polished with a polishing liquid composition containing cerium oxide abrasive grains was prepared. The content of Al contained in the substrate was 8.6% by weight, the content of Si was 27.1% by weight, and the content of Na was 6.0% by weight. These values were measured using the ESCA method under the following measurement conditions.

[0093] 〔ESCA measurement conditions〕

[0094] ·Sample making

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com