Light-emitting device and method for manufacturing the same

A technology for light-emitting devices and light-emitting bodies, which can be applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as poor low-temperature characteristics, poor productivity, and deterioration, and achieve the effects of excellent low-temperature characteristics, less internal damage, and excellent weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Using a kneader, 100 parts by mass of the above (a-1), 15 parts by mass of the above (c-1), and 4.5 parts by mass of the surface treatment (c-1) were prepared while heating at 170°C for 2 hours The above-mentioned (f-1) of the agent and 1 mass part of ion-exchanged water were kneaded uniformly to prepare an unvulcanized silicone compound A.

[0083] Using twin rollers, 100 parts by mass of unvulcanized silicone compound A, 0.2 parts by mass of vinyl siloxane complex of chloroplatinic acid (b-1), 0.7 parts by mass of curing agent (b-2 ) and 0.2 parts by mass of vinylcyclohexanol as a control agent of (b-1) were kneaded to obtain a silicone composition A.

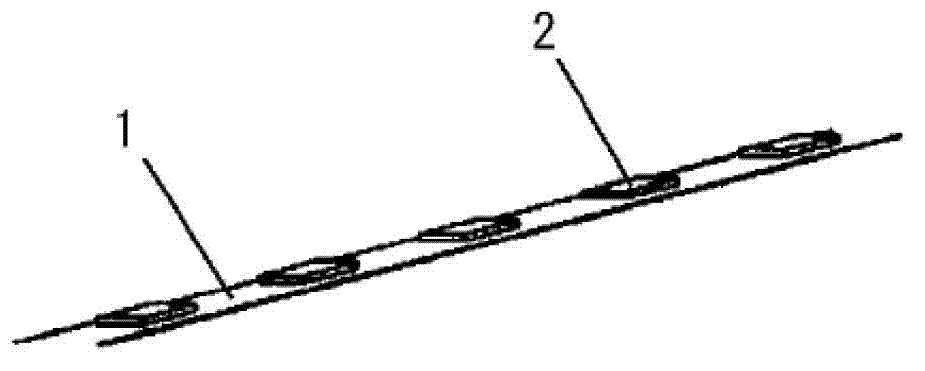

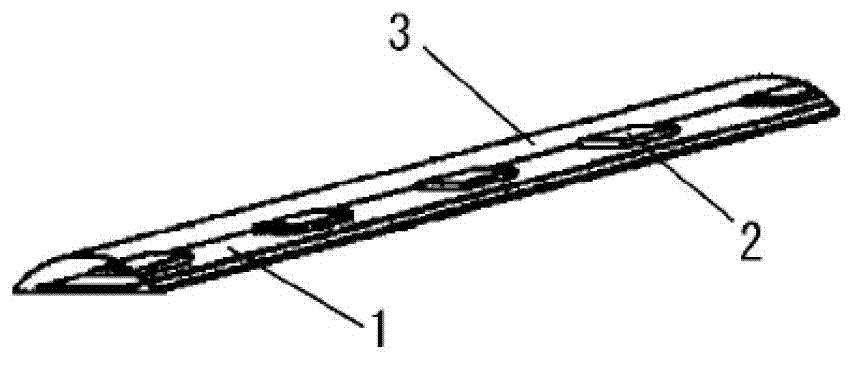

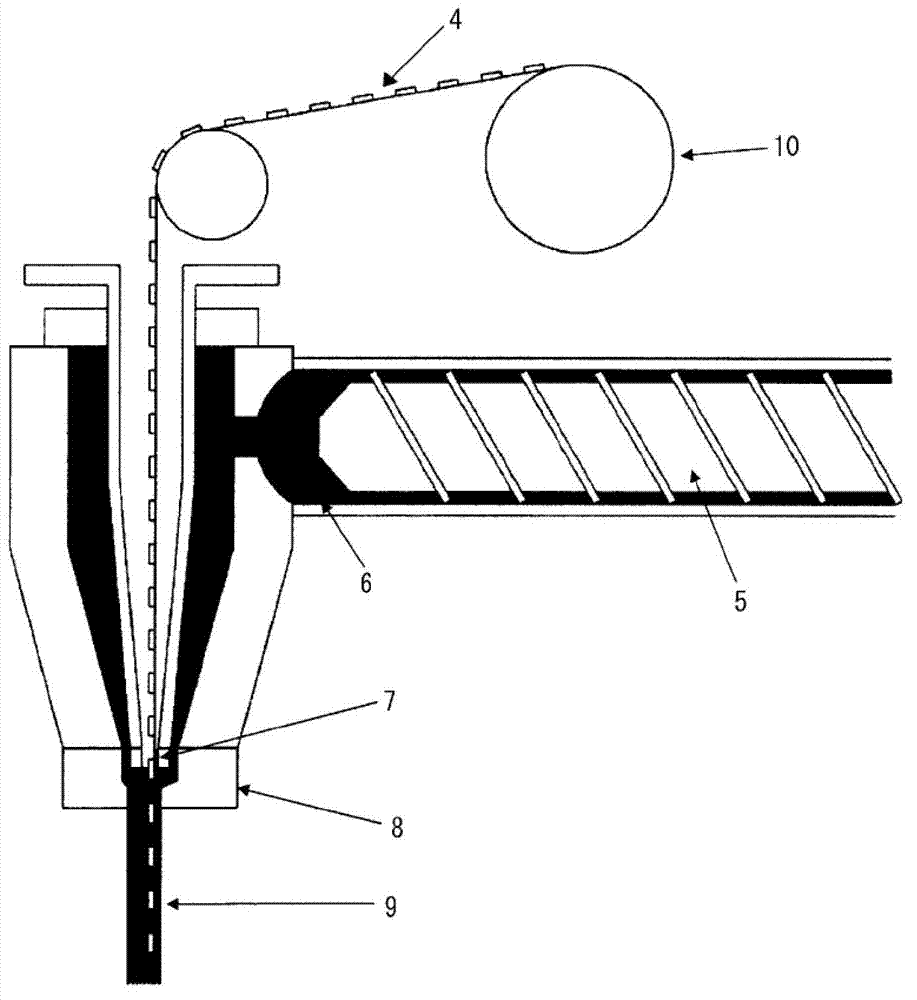

[0084] by image 3 In the manner shown, the silicone composition A and the core material formed by connecting multiple LED components to the flexible circuit board are inserted simultaneously from different insertion ports, and extrusion molding is performed at a speed of 1m / min. , and then, it was cured at 130° C. f...

Embodiment 2

[0086] Except that in 100 parts by mass of the silicone composition A of Example 1, 3 parts by mass of titanium oxide (color tone adjusting agent) with an average particle diameter of 3 μm was further prepared to make the silicone composition B, the rest were the same as the implementation Example 1 was carried out in the same manner to obtain a molded product. The obtained molded article was evaluated as follows.

Embodiment 3

[0088] Using a kneader, while heating at 170°C for 2 hours, 100 parts by mass of the above (a-2), 10 parts by mass of the above (c-1), and 4.5 parts by mass of the surface treatment as (c-1) were prepared The above-mentioned (f-1) of the agent and 1 mass part of ion-exchanged water were kneaded uniformly to prepare an unvulcanized silicone compound B.

[0089] A molding was obtained in the same manner as in Example 2 except that the unvulcanized silicone compound B was used instead of the unvulcanized silicone compound A. The obtained molded article was evaluated as follows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com