Instant litchi chinensis powder and preparation method thereof

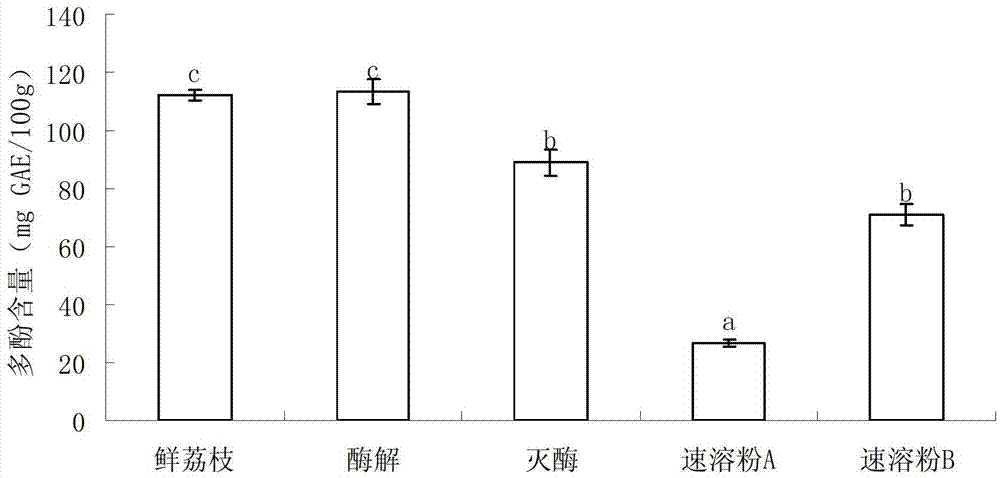

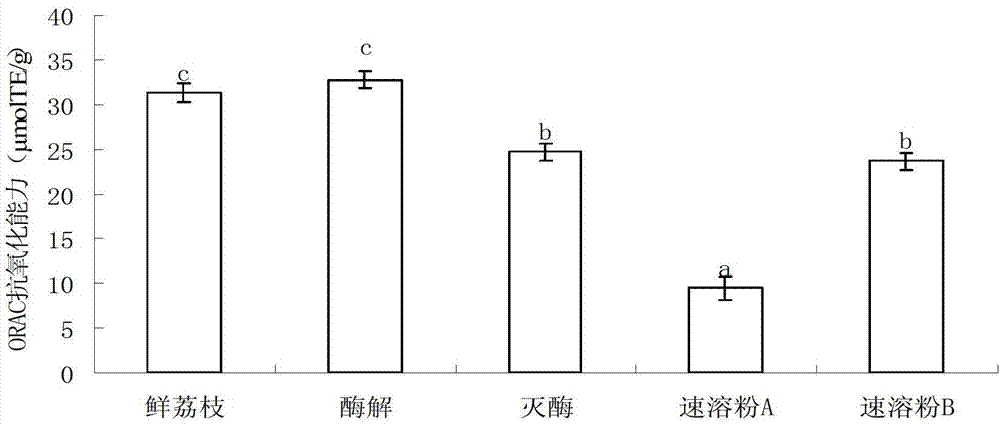

A technology of instant powder and lychee, which is applied in the direction of food preparation, application, food science, etc., can solve the problems of large amount of addition, easy moisture absorption of products, etc., and achieve improved dissolution rate, increased total soluble solid content, and polyphenol active substances The effect of high content and antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

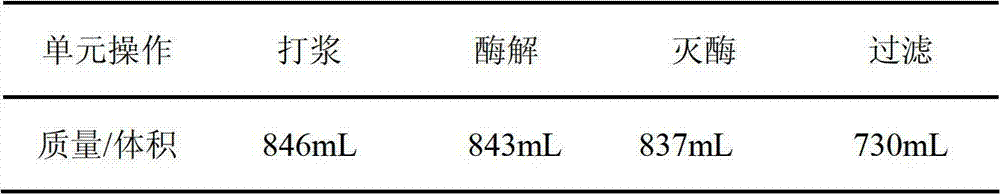

[0022] Fresh lychees are peeled and pitted, beaten, added with 1g / kg of pectinase at 45°C for 1.5h, inactivated at 80°C for 2min, filtered through 200-mesh gauze to obtain litchi juice. Determination of soluble solids content in litchi juice. Add sodium caseinate accounting for 1% by mass of the total soluble solids in the lychee juice to the lychee juice and mix evenly. -0.1KPa, use a rotary evaporator at 50°C to vacuum concentrate the lychee juice until the soluble solid content in the lychee juice is 10%, heat the lychee juice to 50°C in a water bath, at an inlet temperature of 180°C, an inflow volume of 160mL / h, and a hot air flow rate of 24m 3 Spray-dried under the condition of / h, after cooling, litchi instant powder was obtained, and the yield was 45.65%.

Embodiment 2

[0024] Fresh lychees are peeled and pitted, beaten, added with 2g / kg of pectinase at 45°C for 1.5h, inactivated at 80°C for 2min, filtered through 200-mesh gauze to obtain litchi juice. Determination of soluble solids content in litchi juice. Add sodium caseinate accounting for 3% by mass of the total soluble solids in the lychee juice to the lychee juice and mix evenly. -0.1KPa, use a rotary evaporator at 50°C to vacuum concentrate the lychee juice to a soluble solid content of 25%, heat the lychee juice to 50°C in a water bath, at an inlet temperature of 170°C, an inflow volume of 240mL / h, and a hot air flow rate of 17m 3 It was spray-dried under the condition of / h, and after cooling, litchi instant powder was obtained with a yield of 51.08%.

Embodiment 3

[0026] Fresh lychees are peeled and pitted, beaten, added with 3g / kg of pectinase at 45°C for 1.5h, inactivated at 80°C for 2min, filtered through 200-mesh gauze to obtain litchi juice. Determination of soluble solids content in litchi juice. Add sodium caseinate accounting for 5% by mass of the total soluble solids in the lychee juice to the lychee juice and mix evenly. -0.1KPa, use a rotary evaporator at 50°C to concentrate in vacuum until the soluble solids content in the litchi juice is 50%, heat the litchi juice to 50°C in a water bath, at an inlet temperature of 180°C, a liquid intake of 200mL / h, and a hot air flow rate of 21m 3 It was spray-dried under the condition of / h, and after cooling, litchi instant powder was obtained with a yield of 53.79%.

[0027] Taking the lychee instant powder that the present invention makes as an example to carry out physicochemical property analysis, further elaborate the beneficial effect process of the present invention as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com