Efficient vanadium extraction method by performing alkali roasting on vanadium mineral

A roasting and mineral technology, applied in the field of vanadium chemical metallurgy, can solve the problems of toxic gas acidic ammonia nitrogen wastewater, low vanadium conversion rate recovery rate, low vanadium recovery rate, etc., achieve high-efficiency leaching, avoid oxidation wrapping and leaching obstacles, and save viscosity The effect of binder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

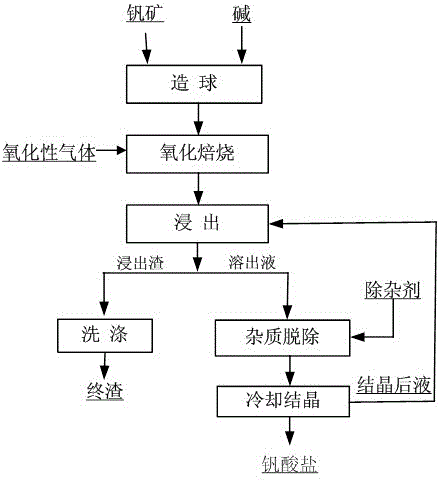

[0018] Example 1: figure 1 As shown, the process steps of the method for efficiently extracting vanadium by alkaline roasting of vanadium-containing minerals are as follows.

[0019] (1) Ingredients: 1kg of vanadium-titanium magnetite and 100g of NaOH are pelletized in a disc granulator to obtain pellets; among them, vanadium-titanium magnetite contains V 2 o 5 1.2wt%, SiO 2 6.5wt%;

[0020] (2) Reaction: Put the pellets into a box kiln and heat them to 350°C for 5 hours. After the reaction, the low-valent vanadium is oxidized to pentavalent and reacts with NaOH to form sodium vanadate to obtain roasted clinker;

[0021] (3) Leaching: leaching the roasted clinker obtained in step (2) in water at 80°C, roasted clinker:water=5:1 (weight); then filter to obtain leaching residue and vanadium-containing eluate;

[0022] (4) Impurity removal: adding a conventional aluminum desiliconization agent to the eluate obtained in step (3) for desiliconization, and filtering to obtain t...

Embodiment 2

[0025] Example 2: The process steps of the method for efficiently extracting vanadium by alkaline roasting of vanadium-containing minerals are as follows.

[0026] (1) Ingredients: 1kg of vanadium slag and 500g of NaOH are pelletized in a disc granulator to obtain pellets; among them, the vanadium slag contains V 2 o 5 12wt%, SiO 2 20wt%;

[0027] (2) Reaction: Put the pellets into a pusher kiln, heat them in oxygen to 500°C for 3 hours, after the reaction, the low-valent vanadium is oxidized to pentavalent and reacts with NaOH to form sodium vanadate to obtain roasted clinker;

[0028] (3) Leaching: Leach the roasted clinker obtained in step (2) in 90°C, 300g / L NaOH solution, the liquid-solid ratio is 5:1 (by weight); then filter to obtain leaching slag and vanadium-containing eluate ;

[0029] (4) Impurity removal: add a conventional calcium desiliconization agent to the eluate obtained in step (3) to remove impurities, and filter to obtain the impurity-removed residue...

Embodiment 3

[0032] Example 3: The process steps of the method for efficiently extracting vanadium by alkaline roasting of vanadium-containing minerals are as follows.

[0033] (1) Ingredients: 1000g of vanadium extraction tailings and 300g of KOH are pelletized in a disc granulator to obtain pellets; among them, the vanadium extraction tailings contain V 2 o 5 2wt%, SiO 2 20wt%;

[0034] (2) Reaction: Put the pellets into the rotary kiln and heat them in oxygen-enriched air to 700°C for 1 hour. After the reaction, the vanadium oxide reacts with KOH to form potassium vanadate to obtain roasted clinker;

[0035] (3) Leaching: Leach the roasted clinker obtained in step (2) in 50°C, 600g / L KOH solution, the liquid-solid ratio is 5:1 (by weight); then filter to obtain leaching slag and vanadium-containing eluate ;

[0036] (4) Impurity removal: add calcium desiliconization agent to the eluate obtained in step (3) to remove impurities, and filter to obtain the impurity-removed residue and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com