Method for greatly reducing amount of solvent usage in production process of oxfendazole

A production process and usage technology, which is applied in the field of greatly reducing the solvent usage in the production process of ofendazole, can solve the problems of increasing the solvent amount, difficult to tolerate the precipitation of crystals of B crystal form, uneconomical, etc., and achieves the reduction of solvent usage. Quantity, process operation is simple, the effect of saving the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

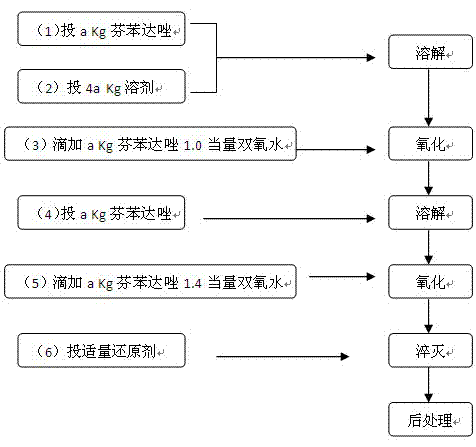

[0020] Add 100.0g fenbendazole and 400.0g formic acid to a 1000ml four-necked flask with a thermometer and a stirring device. Start stirring. After the materials are dissolved, start adding 41.3Kg of hydrogen peroxide (concentration 27.5%) dropwise, and keep the temperature at 20. ~25℃, the dripping is completed in about 1.5 hours. After the addition of hydrogen peroxide is completed, 100.0 fenbendazole is added to the reaction system. After the added fenbendazole is dissolved, 57.8Kg of hydrogen peroxide (concentration of 27.5%) is added. ), the temperature is maintained at 20-25℃, and the dripping is completed in about 1.5 hours. After the addition of hydrogen peroxide is completed, take samples and control them. After the reaction is over, 70.0 g of sodium sulfite aqueous solution (concentration 16.5%) is added to the system to quench the reaction. Then the solvent was concentrated by distillation under reduced pressure. After the solvent was distilled, 600g of methanol was ...

Embodiment 2

[0022] Add 100.0g fenbendazole and 400.0g mixed solvent (ethanol:concentrated sulfuric acid=20:1) into a 1000ml four-necked flask with a thermometer and a stirring device. When the materials are dissolved, start adding 41.3Kg of hydrogen peroxide ( The concentration is 27.5%), the temperature is kept at 20~25℃, and the dripping is completed in about 1.5 hours. After the addition of hydrogen peroxide is completed, 100.0 fenbendazole is added to the reaction system. After the added fenbendazole is dissolved, start Add 57.8Kg of hydrogen peroxide (concentration of 27.5%) dropwise, keep the temperature at 20-25°C, and complete the dropwise addition in about 1.5 hours. After the addition of hydrogen peroxide dropwise, the sampling is controlled, and after the reaction is over, 70.0 g of sodium sulfite aqueous solution (concentration 16.5%) is added to the system to quench the reaction. Then 41.0g of ammonia water (concentration of 25.0%) was added dropwise to the reaction system, an...

Embodiment 3

[0024] Add 100.0g of fenbendazole and 400.0g of mixed solvent (ethanol:chloroform:concentrated hydrochloric acid=2:2:1) into a 1000ml four-necked flask with a thermometer and a stirring device. Add 41.3Kg of hydrogen peroxide (concentration of 27.5%), keep the temperature at 20-25°C, and complete the dripping in about 1.5 hours. After the dripping of hydrogen peroxide is completed, add 100.0 fenbendazole to the reaction system, and the fenbendazole to be added After the azole is dissolved, start to add 57.8Kg of hydrogen peroxide (concentration 27.5%) dropwise, keep the temperature at 20-25°C, and complete the dropwise addition in about 1.5 hours. After the addition of hydrogen peroxide dropwise, the sampling is controlled, and after the reaction is over, 70.0 g of sodium sulfite aqueous solution (concentration 16.5%) is added to the system to quench the reaction. Then 65.0g of ammonia water (concentration of 25.0%) was added dropwise to the reaction system, and the solvent was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com