Rare earth catalyzed nitrocarburizing technology

A technology of nitrocarburizing and rare earth, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of small depth of infiltration layer and insufficient utilization of infiltration agent, etc., and achieves smooth hardness gradient and dispersion The effect of increased hardness and increased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

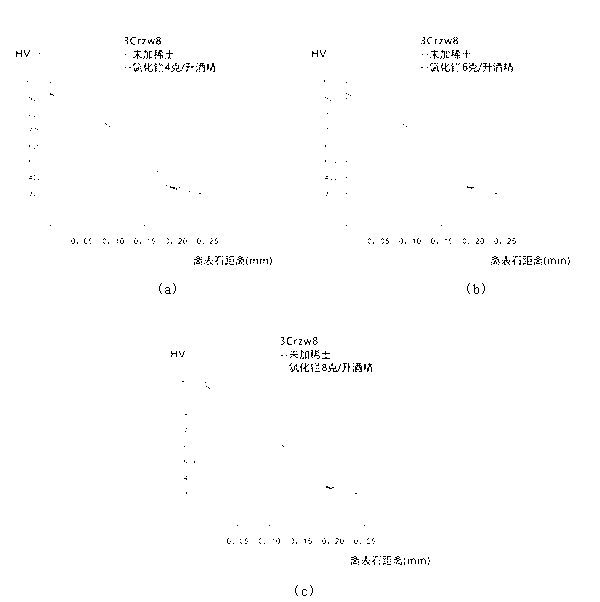

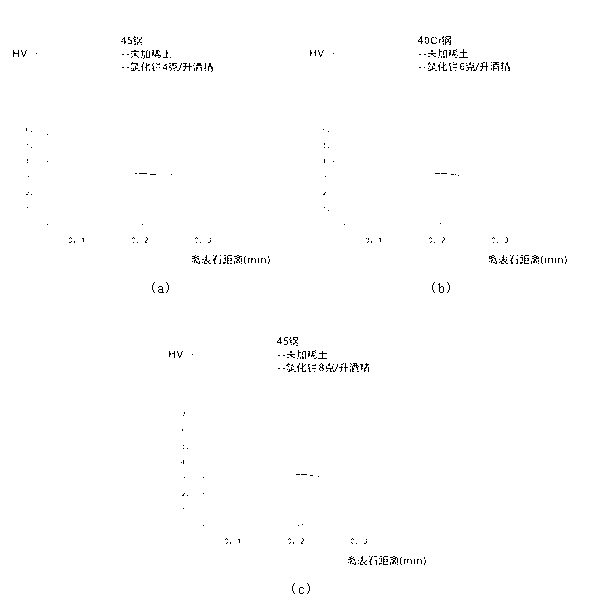

[0027] 3Cr2W8, 40Cr and 45 steels were selected as test materials, and the specific sample materials and sizes were 18*5, 25*4, 22*4.1, and the substrates were all in quenched and tempered state.

[0028] Dissolve lanthanum chloride compound in ethanol to prepare rare earth mixed penetrating agent. The maximum solubility of lanthanum chloride in ethanol is about 12 g / L according to the self-solubility test (with no precipitation in the solution after the addition of rare earth substances). The lanthanum chloride addition used was 4 g / L ethanol.

[0029] The equipment used is the JT-60 well-type gas nitrocarburizing furnace of our factory, and the working room size: ?450×600mm.

[0030] In this embodiment, a carburizing agent and a nitriding agent are introduced during the nitrocarburizing process. The carburizing agent is methanol or acetone, and the nitriding agent is ammonia.

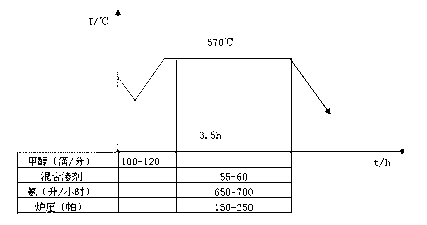

[0031] This embodiment is carried out in conjunction with actual production, using the conventi...

Embodiment 2

[0033] Embodiment 2 is the same as embodiment 1, and difference is: the lanthanum chloride addition that adopts is 6 grams / liter ethanol.

Embodiment 3

[0035] Embodiment 3 is the same as embodiment 1, and the difference is: the lanthanum chloride addition that adopts is 8 grams / liter ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com