Wool and rabbit fur coat

A wool and rabbit fleece technology, applied in the field of wool rabbit fleece coats, can solve the problems of high rigidity of coarse wool, easy shedding, difficulty in spinning, etc., and achieve the effect of high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Wool rabbit cashmere coat, the warp yarn is pure cashmere yarn with a coarse content of 0.8%, and the weft yarn is a composite wool yarn blended with wool fiber and milk protein fiber at a mass ratio of 10:1, and the wool fiber has a fineness of 18 μm and a length of 22 mm. The milk protein fiber has a fineness of 25 μm and a length of 33 mm.

[0016] The cashmere yarn is made by removing the roughness and sorting of rabbit hair, and then undergoing the processes of blending, carding, and spinning. The process of blending and opening the wool is mechanically mixed and opened, and a compound antistatic agent 2% is added to make the hair stuffy. 3 hours; the first car in the combing process is 130 revolutions / min, and the rear car is 120 revolutions / min.

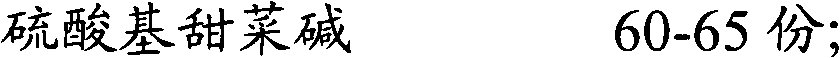

[0017] Preparation of composite antistatic finishing agent:

[0018]

[0019] Sulfate betaine, polyoxyethylene alkyl ether and magnesium chloride are mixed in proportions, and then the silane coupling agent and sodium polyacr...

Embodiment 2

[0021] Wool rabbit cashmere coat, the warp yarn is pure cashmere yarn with a coarse content of less than 0.3%, and the weft yarn is a composite wool yarn blended with wool fiber and milk protein fiber at a mass ratio of 10:3. The wool fiber has a fineness of 22μm and a length of 25mm. The milk protein fiber has a fineness of 32 μm and a length of 38 mm.

[0022] The cashmere yarn is made by removing the roughness and sorting of rabbit hair, and then undergoing the processes of blending, carding, and spinning. The process of blending and unwinding is made by mechanically mixing and opening, and adding 3.5% compound antistatic agent to make the hair stuffy. 2 hours; 150 revolutions per minute for the front car and 130 revolutions per minute for the rear car in the combing process.

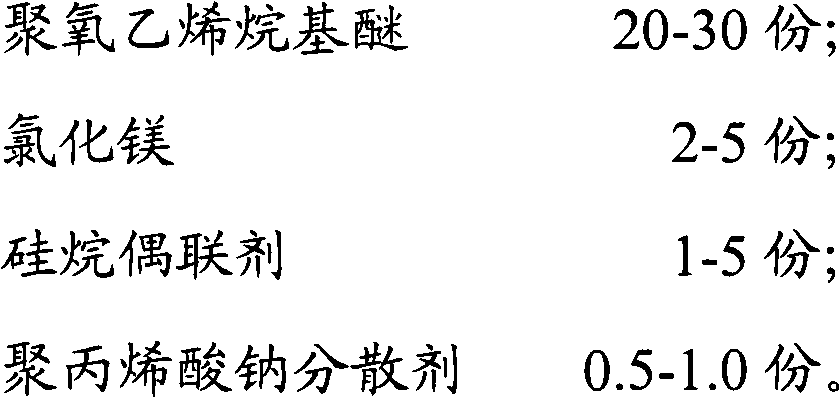

[0023] Preparation of composite antistatic finishing agent:

[0024]

[0025] Sulfate betaine, polyoxyethylene alkyl ether and magnesium chloride are mixed in proportions, and then the silane coupling agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com