Parallelism-adjustable micro-electro-mechanical system Fabry-Perot cavity wavelength tunable filter

A Fabry-Perot cavity, MEMS technology, applied in instruments, optical components, optics, etc., can solve problems such as inability to guarantee parallelism, inability to adjust the distortion of cavity surface topography, and limit the practicability of filters, etc. Achieve the effect of high practicability, elimination of performance impact, and elimination of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

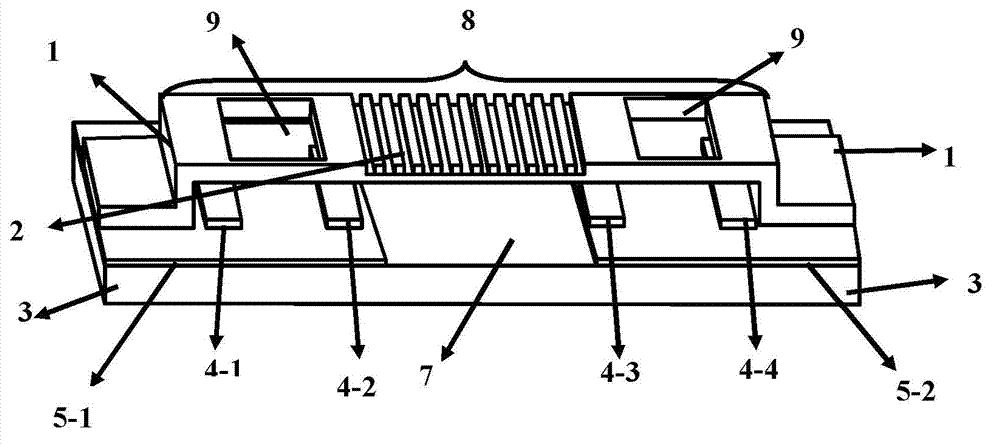

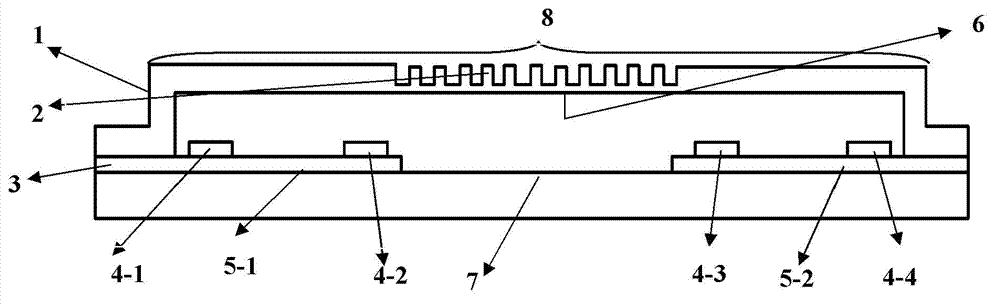

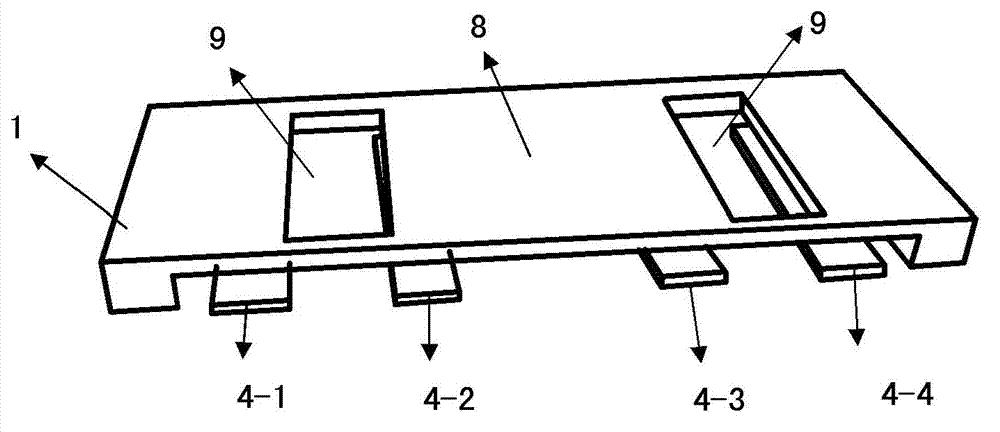

[0029] figure 1 and figure 2 It is a perspective view and a side view of a MEMS Fabry-Perot cavity wavelength tunable filter (hereinafter referred to as the filter) with adjustable parallelism in this embodiment; it includes: a micro-bridge part 1, a grating 2, a substrate 3. A plurality of lower electrodes 4, a first insulating layer 5-1, a second insulating layer 5-2, an anterior cavity surface 6, a rear cavity surface 7, a bridge surface 8 and two rectangular holes 9, wherein: the micro bridge part 1 , has a bridge surface 8, the bridge surface 8 is used as the upper electrode of the Fabry-Perot cavity; the grating 2 is located at the center of the bridge surface 8 of the micro-bridge part 1, and is integrated together; the substrate 3 is used as the bottom layer; multiple A lower electrode 4 is distributed under the micro-bridge part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com