Non-contact 485 bus on-line monitoring device having direction detection

A non-contact, monitoring device technology, applied in the circuit field, can solve problems such as code errors, inconvenient operation, and affecting system security, etc., to achieve the effect of ensuring equipment safety and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

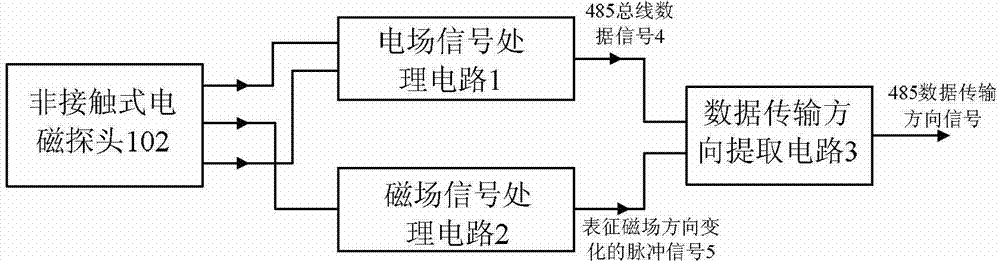

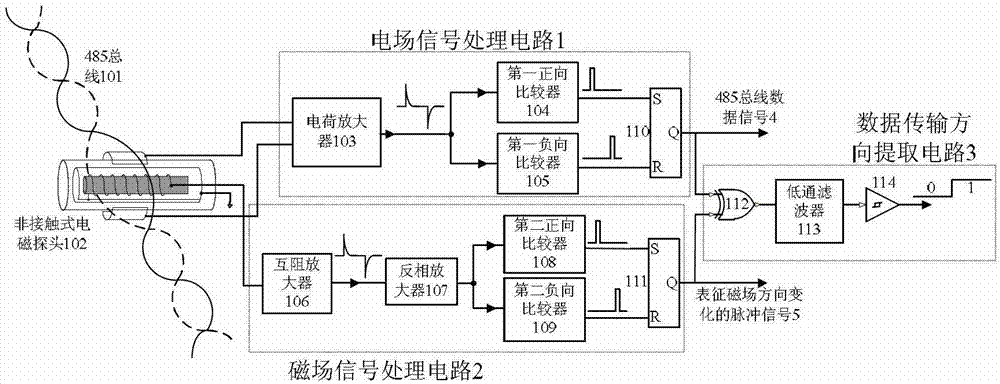

[0040] refer to figure 1 , the non-contact 485 bus online monitoring device with direction detection of the present invention includes a non-contact electromagnetic probe 102 , an electric field signal processing circuit 1 , a magnetic field signal processing circuit 2 and a data transmission direction extraction circuit 3 .

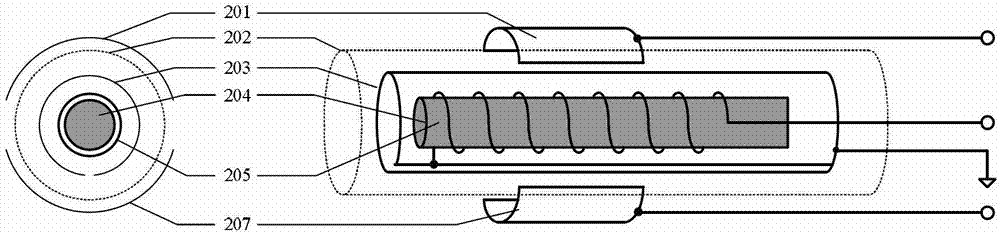

[0041] The non-contact electromagnetic probe 102 is used to simultaneously induce the electric field change signal of the two differential lines of the 485 bus and the magnetic field change signal between the two lines during the test, and output the electric field signal to the electric field signal processing circuit 1, and proceed sequentially. Through electric field signal transformation, amplification, shaping and information extraction, the data signal 4 of the 485 bus is restored; the magnetic field signal is output to the magnetic field signal processing circuit 2, and the signal transformation, amplification, shaping and information extraction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com