Sow fermented feed and production method thereof

A fermented feed and breeding sow technology, applied in animal feed, animal feed, application, etc., can solve the problems of not being able to improve the production performance of sows, and achieve the goals of preventing sows from constipation, promoting feed intake, good digestion and absorption, and utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

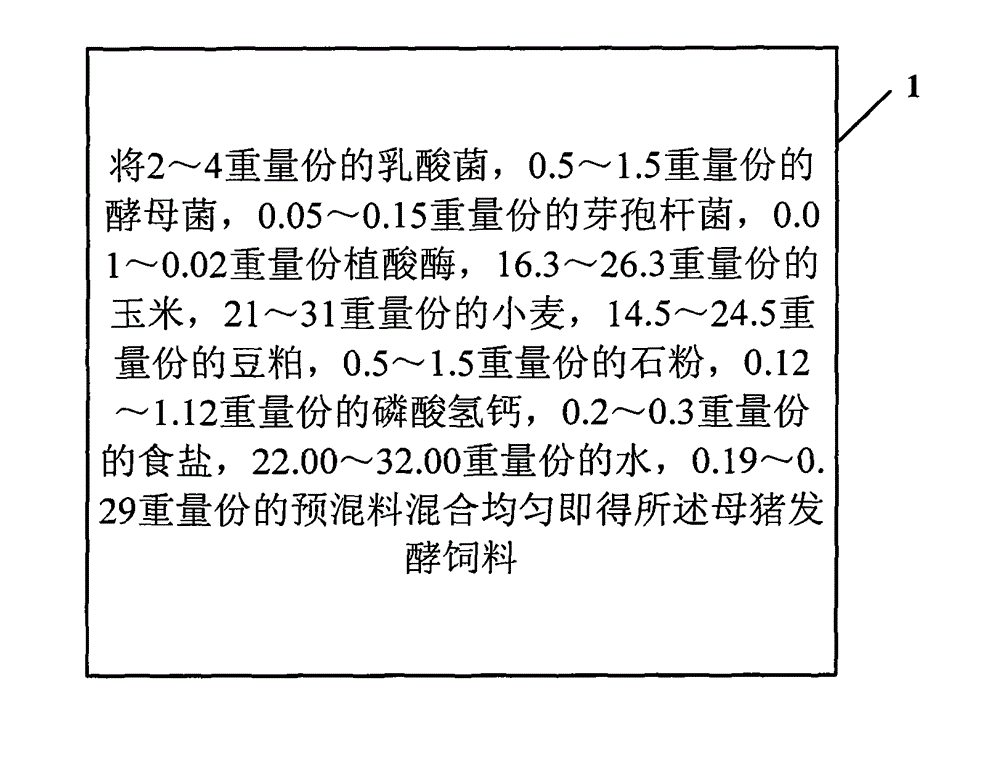

[0055] The lactic acid bacteria of 2 parts by weight, the saccharomycete of 0.5 parts by weight, the bacillus of 0.05 parts by weight, the phytase of 0.01 parts by weight, the corn of 16.3 parts by weight, the wheat of 21 parts by weight, the soybean meal of 14.5 parts by weight, 0.5 parts by weight The stone powder of 0.12 parts by weight of calcium hydrogen phosphate, the salt of 0.2 parts by weight, the water of 22.00 parts by weight, and the premix of 0.19 parts by weight are evenly mixed to obtain the fermented feed for sows.

[0056] The premixed material is 0.05 parts by weight of compound organic trace elements, 0.035 parts by weight of compound vitamins and 0.05 parts of compound electrolyte.

Embodiment 2

[0058] 3 parts by weight of lactic acid bacteria, 1 part by weight of yeast, 0.1 part by weight of bacillus, 0.015 parts by weight of phytase, 21.3 parts by weight of corn, 26 parts by weight of wheat, 19.5 parts by weight of soybean meal, 1 part by weight of The stone powder of 0.62 parts by weight of calcium hydrogen phosphate, the salt of 0.25 parts by weight, the water of 27.00 parts by weight, and the premix of 0.24 parts by weight are evenly mixed to obtain the fermented feed for sows.

[0059] The premixed material is 0.1 parts by weight of composite organic trace elements, 0.04 parts by weight of multivitamins and 0.1 parts by weight of composite electrolytes.

Embodiment 3

[0061] The lactic acid bacteria of 4 parts by weight, the saccharomycete of 1.5 parts by weight, the bacillus of 0.15 parts by weight, the phytase of 0.02 parts by weight, the corn of 26.3 parts by weight, the wheat of 31 parts by weight, the soybean meal of 24.5 parts by weight, 1.5 parts by weight The stone powder of 1.12 parts by weight of calcium hydrogen phosphate, the salt of 0.3 parts by weight, the water of 32.00 parts by weight, and the premix of 0.29 parts by weight are evenly mixed to obtain the fermented feed for sows.

[0062] The premixed material is 0.15 parts by weight of composite organic trace elements, 0.045 parts by weight of multivitamins and 0.15 parts by weight of composite electrolytes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com