A kind of directly heat-sealable polyester film and preparation method thereof

A polyester film and a direct technology, applied in the field of polyester film and its preparation, can solve the problems of incapability of self-heat sealing and the like, and achieve the effects of saving compounding processes, preventing the existence of residual solvents, and saving use and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]A polyester film that can be directly heat-sealed, including an ABC three-layer structure, the B layer is the middle core layer, and the material is PET super-bright polyester chips; the A layer is the surface heat-sealing layer, and the material is copolymerized PETG Polyester chips; C layer is an anti-blocking layer, and the materials include PET anti-blocking agent masterbatch chips and PET super glossy polyester chips.

[0031] The anti-adhesion layer of layer C has the following components by mass percentage: 30%-60% of PET anti-adhesion agent masterbatch chips and 40%-70% of PET super-bright polyester chips.

[0032] The thickness of layer B accounts for 70% to 80%, the thickness of layer A accounts for 10% to 20%, and the thickness of layer C accounts for 10% to 20%.

[0033] The copolymerized PETG polyester chip of the heat-sealing layer on the surface layer of layer A is made of dimethyl terephthalate DMT, ethylene glycol EG, silicon dioxide SiO 2 And 1,4-cyclo...

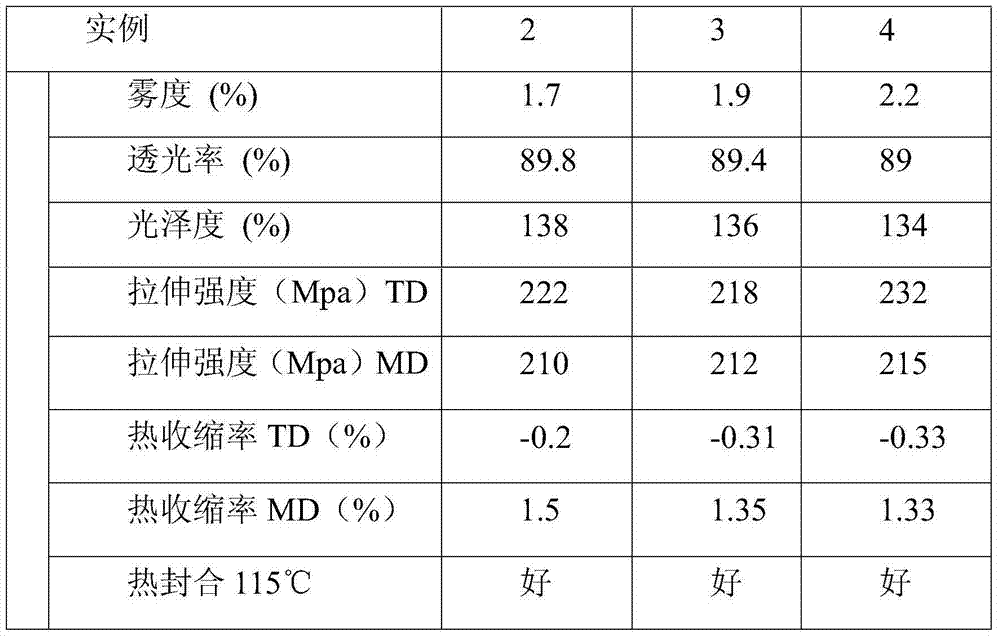

Embodiment 2

[0051] A method for preparing a directly heat-sealable polyester film, in parts by weight: 22 parts by mass of 1,4 cyclohexanedimethanol CHDM and 3 parts by mass of silicon dioxide SiO 2 Add to 23 parts of ethylene glycol EG, stir and disperse, then homogenize through high-speed dispersion, and use ultrasonic vibration to disperse, then send it to the polymerization kettle of the main reaction system; add 100 parts of dimethyl terephthalate DMT to stir and mix, Then add 2 parts (PTA weight) of antimony trioxide and triphenyl phosphite, and use nitrogen gas N 2 Replace 3 times. Under the pressure of 600Pa in the kettle, the temperature was raised to 180°C, and the esterification reaction was carried out for 0.8h. After the esterification reaction was completed, the excess ethylene glycol EG was recovered; then the temperature was raised to 260°C, and the polymerization was performed under vacuum for 3.4h. Cut into pellets to obtain copolymerized PETG polyester chips.

[0052]...

Embodiment 3

[0054] The difference between this embodiment and embodiment 2 is that the mass ratio of the extruded material from the main extruder and two auxiliary twin-screw extruders is 15:70:15, the thickness of the heat-sealing layer of the 20um film A layer is 3.0um, and the C The thickness of the anti-adhesion layer is 3.0um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com