Method for preparing aggregation induced emission (AIE) group functionalized laminar zirconium phosphate material by ion exchange method

A technology of aggregation-induced luminescence and ion-exchange method is applied in the field of preparing layered zirconium phosphate materials functionalized with aggregation-induced luminescence groups by ion-exchange method, which can solve the problems such as no relevant reports, and achieve lower production costs and good water dispersibility. , easy to adjust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

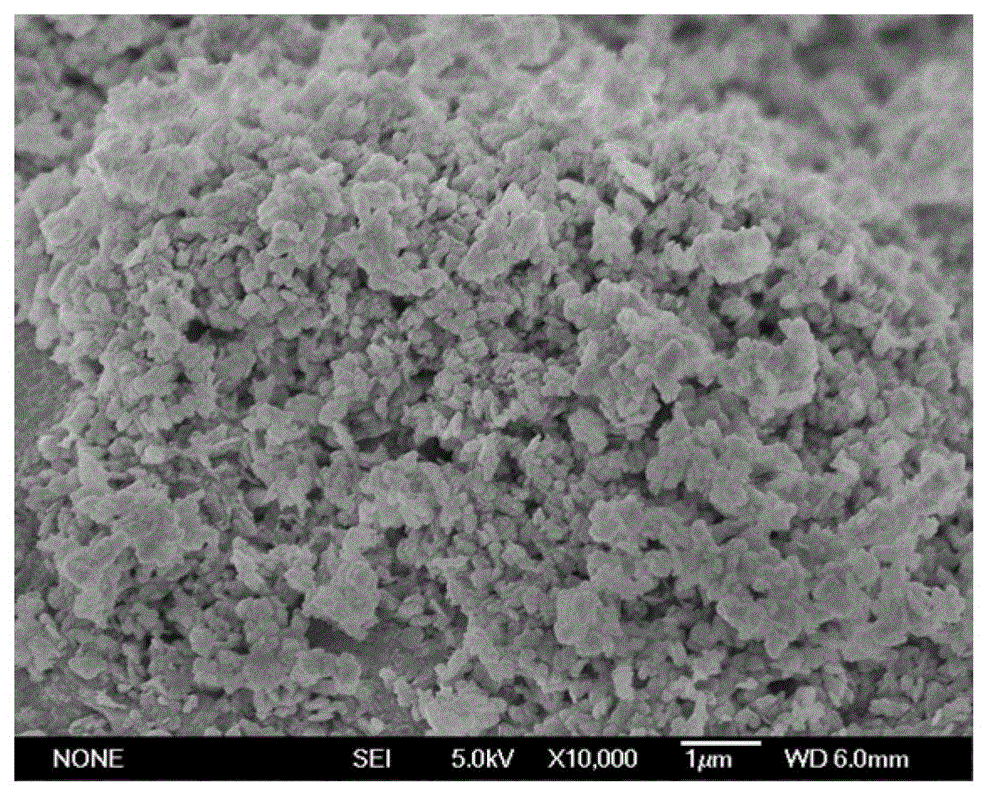

[0035] Ultrasonic disperse 0.5g α-ZrP (particle size about 400nm) in 15mL deionized water to make it fully dispersed, then add 0.07g butylamine, continue ultrasonication for 0.5h, centrifuge (10000rpm, 20min), use a large amount of The solid precursor α-ZrP·BA was obtained after washing with deionized water to neutrality and freeze-drying.

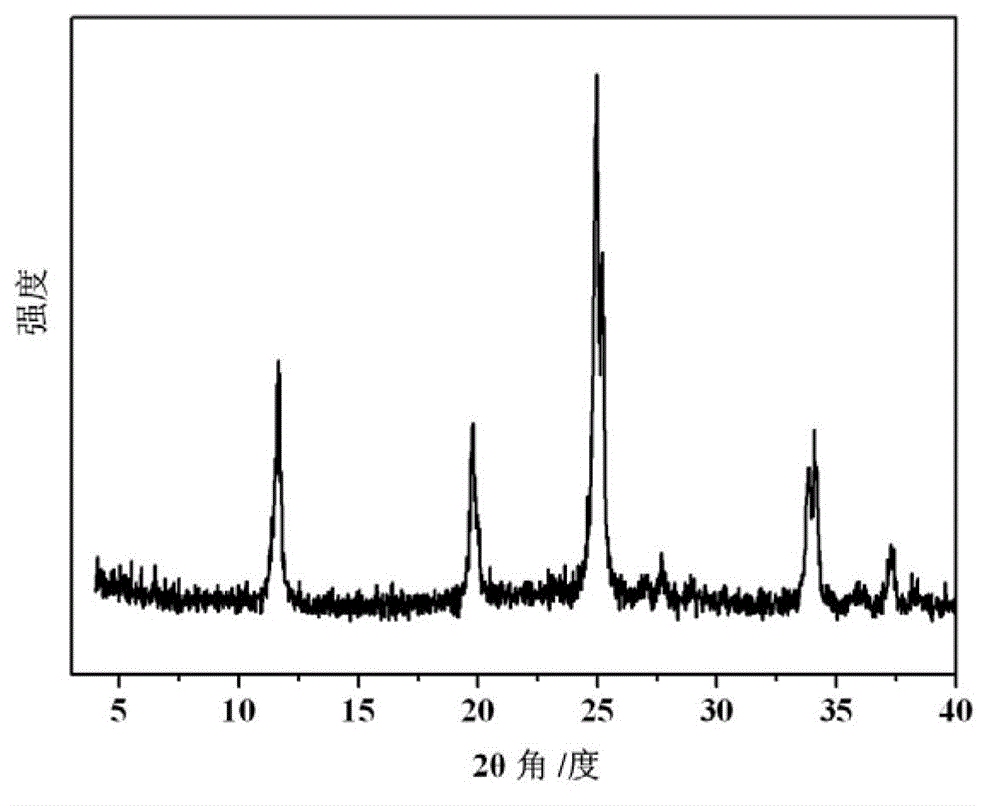

[0036] Weigh 50 mg of α-ZrP·BA, and ultrasonically disperse it into 17 mL of aqueous solution; then add 57.6 mg of TPEN into 33 mL of deionized water, and ultrasonically dissolve it completely. The aqueous solution of TPEN was added to the suspension of the α-ZrP precursor, and the stirring was continued at 40° C. for 24 h to obtain a uniform light yellow suspension. Centrifuge with a high-speed centrifuge (10000rpm, 20min), and wash the solid multiple times with a large amount of deionized water to wash away unreacted TPEN molecules, and then freeze-dry to obtain a layered zirconium phosphate material functionalized by the AIE group. is ...

Embodiment 2

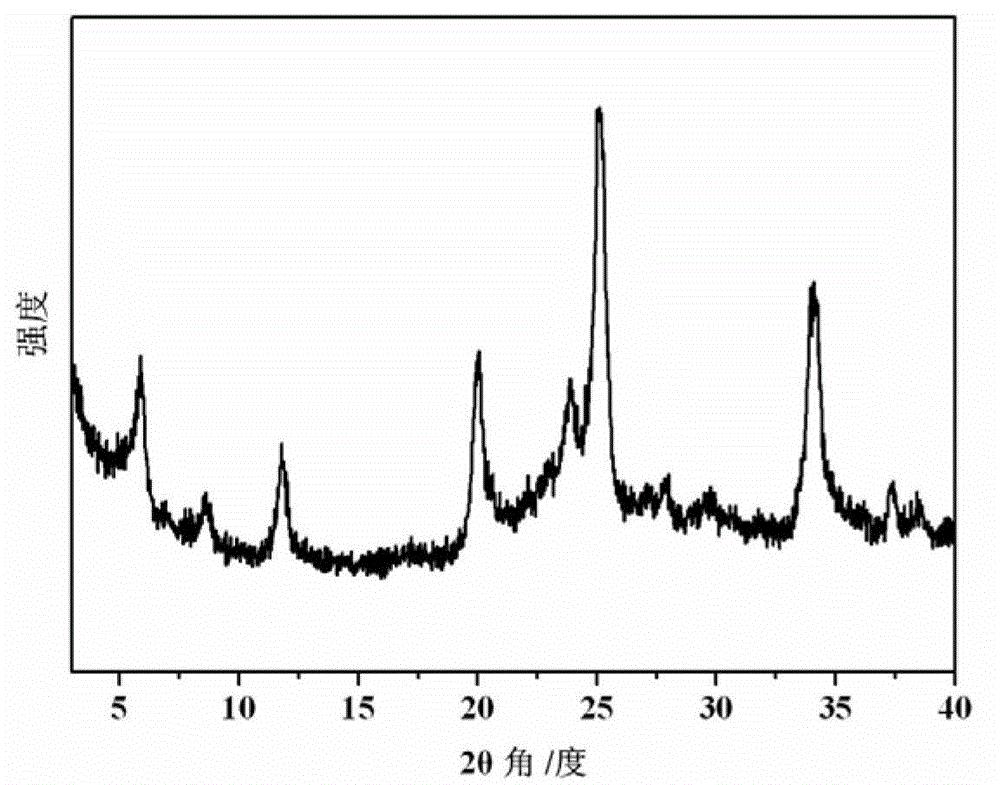

[0038]Weigh 35 mg of α-ZrP·BA in Example 1, ultrasonically disperse it into 10 mL of aqueous solution, add 10 mg of TPEN into 30 mL of deionized water, and ultrasonically dissolve it completely. The aqueous solution of TPEN was added to the suspension of α-ZrP·BA, and the stirring was continued at 40° C. for 24 h to obtain a uniform light yellow suspension. Centrifuge (10000rpm, 20min), and wash the solid several times with a large amount of deionized water to wash away unreacted TPEN molecules, and then freeze-dry to obtain a layered zirconium phosphate material functionalized with AIE groups, with a mass of 36mg.

Embodiment 3

[0040] Weigh 50 mg of α-ZrP·BA in Example 1, ultrasonically disperse it into 17 mL of aqueous solution, add 90 mg of TPEN into 33 mL of deionized water, and ultrasonically dissolve it completely. The aqueous solution of TPEN was added to the suspension of α-ZrP·BA, and the stirring was continued at 40° C. for 24 h to obtain a uniform light yellow suspension. Centrifuge (10000rpm, 20min), and wash the solid several times with a large amount of deionized water to wash away unreacted TPEN molecules, and then freeze-dry to obtain a layered zirconium phosphate material functionalized with AIE groups, with a mass of 56mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com