Two-dimensional carbon material and preparation method and application thereof

A two-dimensional carbon material and two-dimensional material technology, applied in the field of two-dimensional carbon material and its preparation, can solve the problems of complex preparation, difficult mass production, complex preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0088] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0089] Optional means that the feature exists or does not exist, and also means that the feature must exist, but the specific choice can be arbitrary.

Embodiment 1

[0091] (1) Preparation of protonated layered nickel-doped TiO 2

[0092] Anhydrous potassium carbonate, nickel oxide, anatase TiO 2 According to the molar ratio of 1.3:0.2:4, it is prepared by protonating 1M hydrochloric acid after grinding, mixing and tableting at 1150°C for 6 hours.

[0093] (2) intercalation reaction

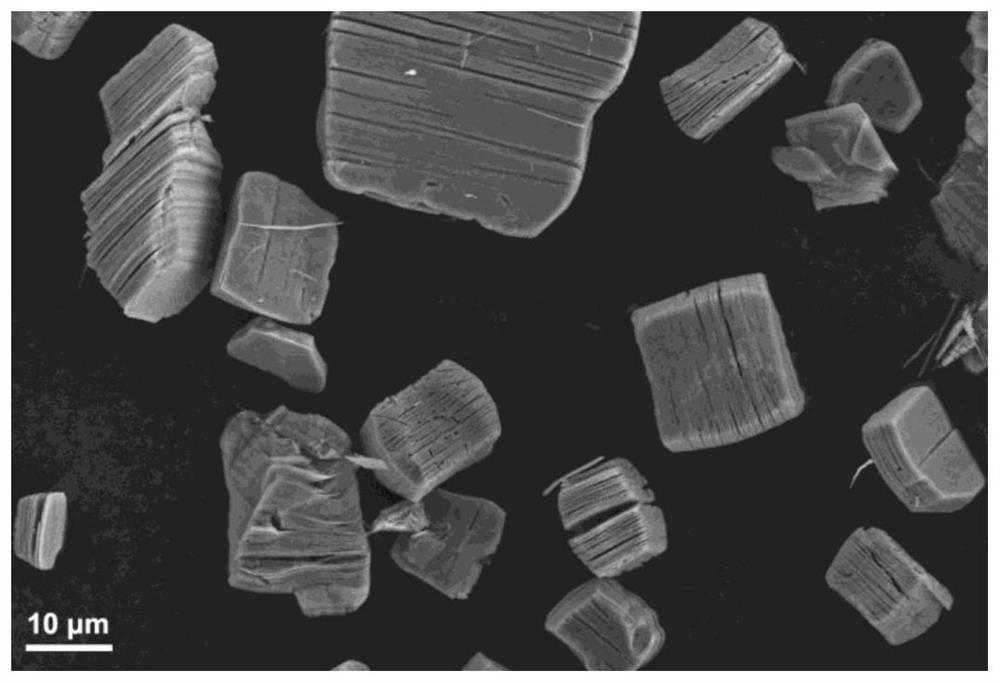

[0094] Take 1.0 g of the protonated layered nickel-doped TiO prepared above 2 Material, 1.0g benzidine, and 60mL ethanol / water (5:1 volume ratio) mixed solution in a 100mL hydrothermal kettle, after ultrasonic dispersion, heated to 100 ° C for 12 hours, cooled to room temperature, filtered, and used a large amount of Washed with ethanol and dried to obtain benzidine / nickel-doped layered TiO 2 Composite two-dimensional material 1.1g. The scanning electron microscope images of the obtained samples are as follows: figure 1 shown.

[0095] (3) Polymerization reaction

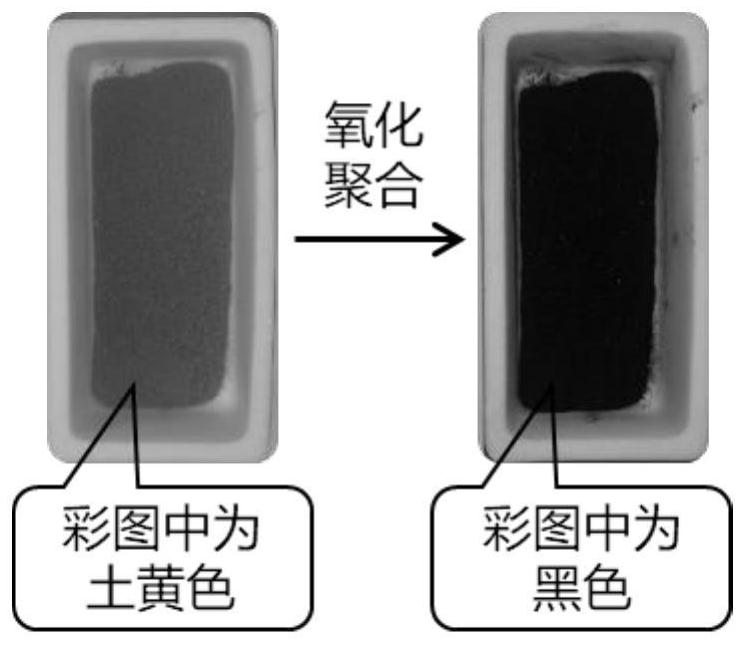

[0096] 1.1 g of the above-prepared benzidine / nickel-doped layered TiO 2 Composite two-...

Embodiment 2

[0104] Other operating steps are with embodiment 1, and difference is only to replace step (4) carbonization reaction in embodiment 1 with following steps:

[0105] (4) Carbonization reaction

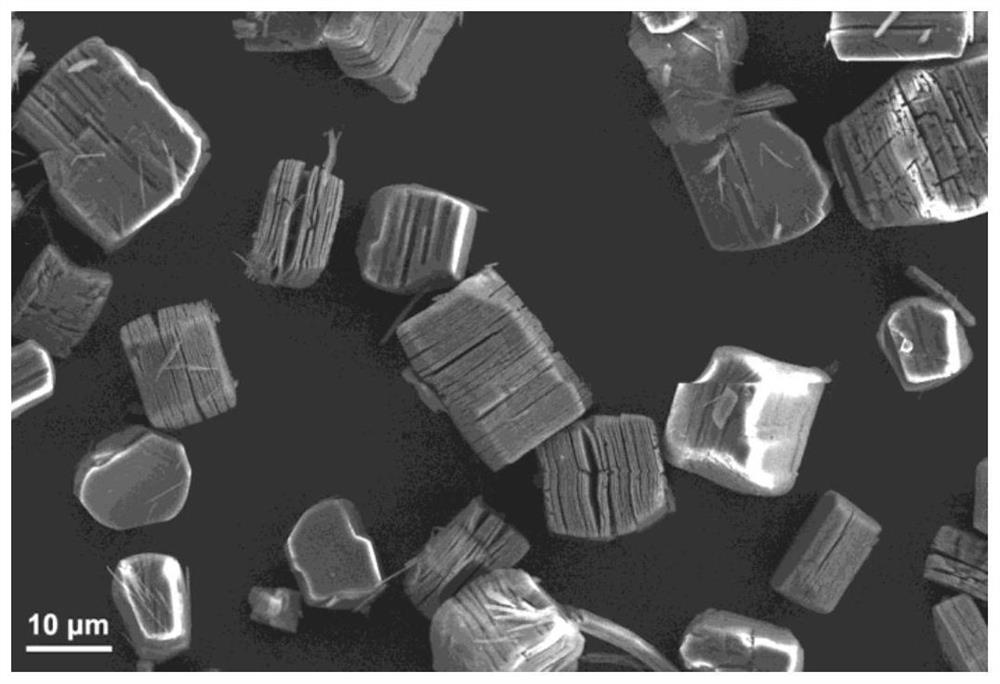

[0106] Take 0.5g of the polybenzidine / nickel-doped layered TiO prepared above 2 The composite two-dimensional material was placed in a corundum crucible, put into a tube furnace, and sintered at 900°C for 3 hours in pure nitrogen gas to obtain 0.41 g of a black solid. Its scanning electron microscope pictures are as Figure 7 shown. Under high temperature reducing atmosphere, doped nickel and layered TiO 2 The nanosheets are sintered into granular nickel metal particles as well as rutile phase TiO 2 .

[0107] (5) De-membrane plate reaction

[0108] Soak the solid material prepared after the above carbonization reaction in a mixed solution of 1mol / L acid 20mL and 5mL ethanol for 1 day, filter and dry in vacuum to obtain carbon / TiO 2Composite two-dimensional material 0.35g, scanni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com