Hydrophilic aluminum foil coating and method for preparing and curing same

A hydrophilic aluminum foil and coating technology, which is applied in the direction of epoxy resin coatings and coatings, can solve the problems of reduced production efficiency, high energy consumption for heating and curing, and is not conducive to environmental protection, and achieves fast curing speed, good adhesion, and hardness. moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Synthesis of Linoleic Acid Modified Epoxy Ester

[0026] (1) Equipped with components according to parts by mass

[0027] E-20 epoxy resin (epoxy value 0.20) 56 parts,

[0028] Diethanolamine 12 parts,

[0029] 32 parts of linoleic acid.

[0030] (2) Preparation

[0031] Weigh 56 parts of bisphenol A epoxy resin E-20 with an epoxy value of 0.2, heat up to 120°C until it melts, then weigh 12 parts of diethanolamine and add it dropwise to the molten epoxy resin for a time of After 0.5 hours, react at 150°C for 1 hour after completion, cool down to 110°C, add 32 parts of linoleic acid with an acid value of 195mg / g to neutralize, until the acid value is less than 5mg / g, cool to obtain a modified epoxy resin.

[0032] 2. Preparation of hydrophilic aluminum foil photocuring coating

[0033] (1) Prepare components according to mass percentage content

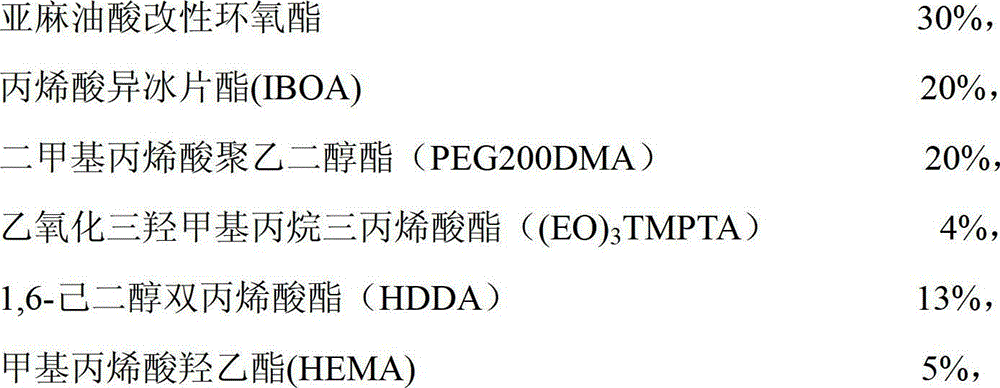

[0034]

[0035]

[0036] (2) Preparation

[0037] In order, add reactive diluents such as modified epoxy resi...

Embodiment 2

[0039] 1. Synthesis of Linoleic Acid Modified Epoxy Ester

[0040] (1) Equipped with components according to parts by mass

[0041] 37 parts of E-44 epoxy resin (epoxy value 0.44),

[0042] Diethanolamine 17 parts,

[0043] 46 parts of linoleic acid.

[0044] (2) Preparation

[0045] Weigh 37 parts of bisphenol A epoxy resin E-44 with an epoxy value of 0.44, heat up to 100°C, weigh 17 parts of diethanolamine, and add it dropwise to the molten epoxy resin at 120°C. After 0.8 hours, react at 130°C for 2 hours after completion, cool down to 100°C, then add 46 parts of linoleic acid with an acid value of 195 mg / g for neutralization until the acid value is less than 5 mg / g, then cool to obtain the modified Sexual epoxy resin.

[0046] 2. Preparation of hydrophilic aluminum foil photocuring coating

[0047] (1) Prepare components according to mass percentage content

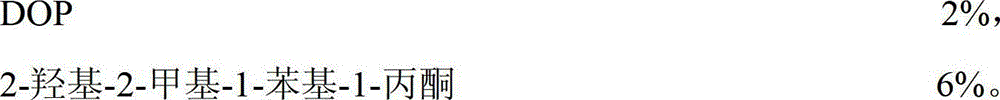

[0048]

[0049] (2) Preparation

[0050] According to the order, add reactive diluents such as modified e...

Embodiment 3

[0052] 1. Synthesis of Linoleic Acid Modified Epoxy Ester

[0053] (1) Equipped with components according to parts by mass

[0054] 33 parts of E-51 epoxy resin,

[0055] Diethanolamine 18 parts,

[0056] 49 parts of linoleic acid.

[0057] (2) Preparation

[0058] Weigh 33 parts of bisphenol A epoxy resin E-51 with an epoxy value of 0.51, heat it up to 90°C, then weigh 18 parts of diethanolamine, and add it dropwise to the molten epoxy resin for 1 hour , then react at 120°C for 3 hours, cool down to 90°C, add 49 parts of linoleic acid with an acid value of 195mg / g to neutralize, until the acid value is less than 5mg / g, cool to obtain modified epoxy fat.

[0059] 2. Preparation of hydrophilic aluminum foil photocuring coating

[0060] (1) Prepare components according to mass percentage content

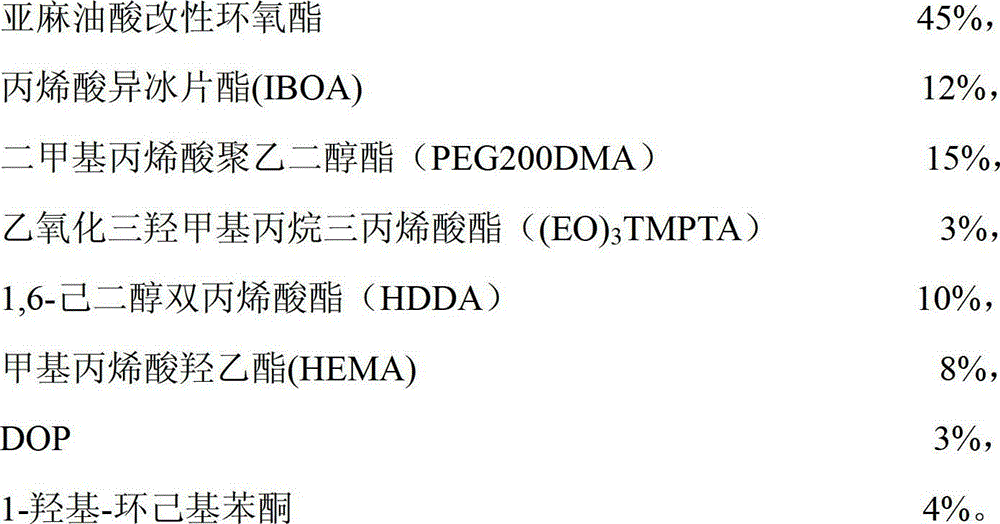

[0061]

[0062] (2) Preparation

[0063] In order, add reactive diluents such as modified epoxy resin, IBOA, and tougheners, and stir at a high speed of 2500 rpm for 15 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com