A kind of diesel oil liquid phase hydrogenation method

A liquid-phase hydrogenation and diesel oil technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, and treatment of hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

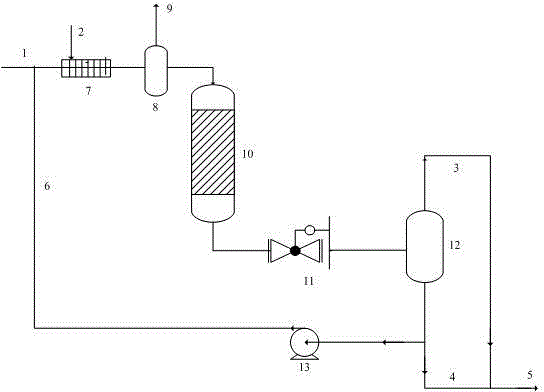

[0024] Embodiment 1~4 adopts the present invention figure 1 process shown. The composition and properties of catalysts used in the following examples are shown in Table 1. The raw material properties used are shown in Table 2, and the process conditions used in Examples 1 to 4 are listed in Table 3. The evaluation results of Examples 1 to 4 are shown in Table 4.

[0025] Table 1 Composition and main properties of catalysts

[0026] project catalyst Chemical composition, mass% MoO 3 6.2 NiO 12.3 WO 3 15.2 carrier Aluminum oxide physical properties Pore volume, mL / g 0.45 Specific surface area, m 2 / g 201

[0027] Table 2 Properties of raw oil

[0028] project Raw oil Density (20℃), g / cm 3 0.8532 Distillation range, ℃ 199~368 Sulfur content, μg / g 8800 Nitrogen content, μg / g 316 Aromatic content, wt % 21

[0029] Table 3 The operating conditions used in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com