Fermentation process of cephalosporin C

A technology of cephalosporin and fermentation method, which is applied in the fields of bioengineering and microbiology, and can solve problems such as the decline of soybean oil utilization capacity, the influence of cephalosporin C extraction, and the poor defoaming effect of soybean oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

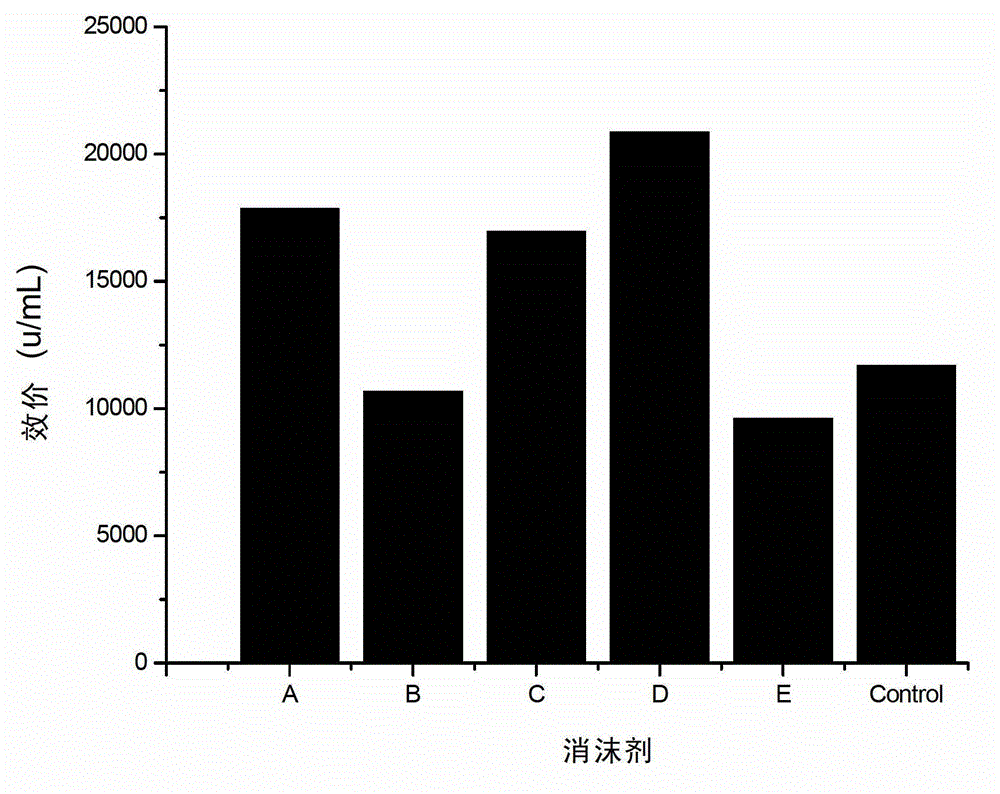

[0064] Embodiment 1, the influence of different kinds of defoamers on the fermentation of cephalosporin C

[0065] On the shake flask culture level, select five antifoaming agents (A, D belong to polyether antifoaming agents, B, E belong to silicone antifoaming agents, and C belong to high carbon alcohol antifoaming agents) according to 0.25% ( The ratio of v / v) was added to the fermentation medium (soybean oil was initially added, and the amount added was the same as that of the control group). The effect of anti-foaming agents on the fermentation of cephalosporin C, see the results figure 1 .

[0066] Among the five defoamers, the potency (u / mL) of A, C, and D was higher than that of the control, and that of B, E was lower than that of the control. Among them, D has the highest titer and E has the lowest potency. It can be seen that polyoxyethylene oxypropylene glycerin has little influence on the fermentation of cephalosporin C (even has a synergistic effect), while sili...

Embodiment 2

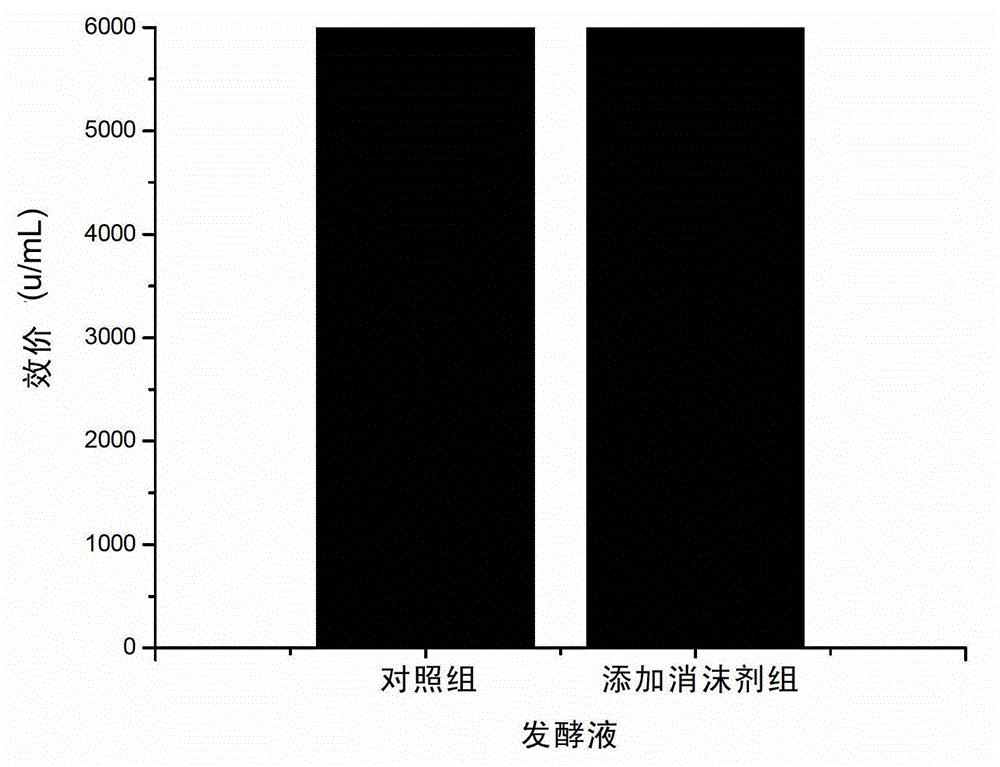

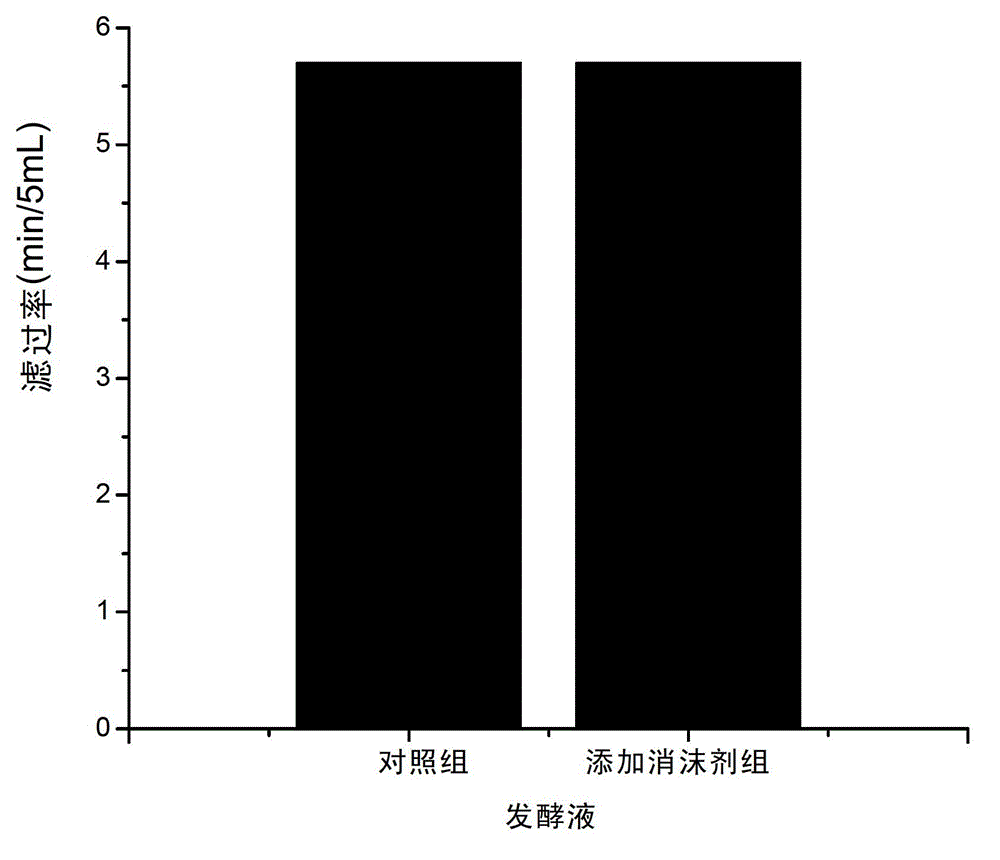

[0069] Embodiment 2, the impact of adding defoamer on the fermentation of cephalosporin C in the fermentation process

[0070] In a 50L fermenter, fermentation was carried out according to the aforementioned "cultivation in a 50L fermenter". Select D defoamer to carry out the supplementary experiment of defoamer, start to add defoamer intermittently through peristaltic pump at 100 hours, when the foam of fermentation broth rises to the position where the total amount of foam and fermentation broth is 35L (observed through the fermenter sight glass ) began to add anti-foaming agent, adding 1.5g of anti-foaming agent each time (that is, the total amount of 0.043g / L foamy fermentation broth). Ammonium sulfate stopped adding after 50 hours. Add soybean oil at a rate of 30g / hr at 50 hours, stop adding soybean oil at 100 hours, and start adding defoamer. The amount of soybean oil supplementation was reduced by about 25% compared with the control group. Control the fermentation li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com