Low anisotropic magnetic alloy material and preparation method thereof

An anisotropic and magnesium alloy technology, applied in the field of magnesium alloy materials and its preparation, can solve the problems that cannot be popularized and used in a large area, the price of rare earth elements is high, and the improvement range is not large, so as to achieve grain refinement and improve mechanical properties , Improve room temperature ductility and deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

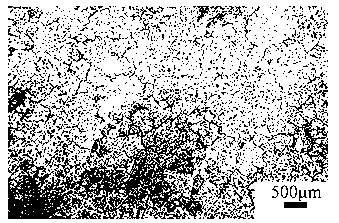

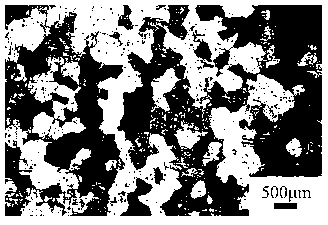

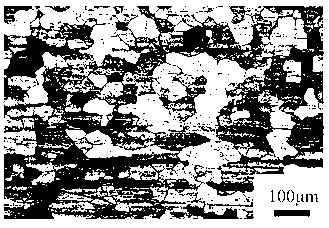

Image

Examples

Embodiment 1

[0037] The low-anisotropy magnesium alloy material of this embodiment consists of the following components by mass percentage:

[0038] Li 1.0%;

[0039] Al 3.0%;

[0040] Zn 1.0%;

[0041] Mn 0.3%;

[0042] Al-5Ti-1B 0.3%;

[0043] Impurities ≤0.3%;

[0044] Magnesium balance;

[0045] The mass percent content of each component in the Al-5Ti-1B is: Ti 5%; B 1%; the balance is Al.

[0046] The preparation method of the low-anisotropy magnesium alloy material of this embodiment is to heat the pure lithium, Al-5Ti-1B master alloy and AZ31 magnesium alloy in the formula amount to 720 ° C under the condition of vacuumizing and feeding inert gas, and wait for After the alloy is completely melted, keep it at 700°C for 15 minutes, then pour the melted alloy liquid into the mold to obtain the as-cast magnesium alloy; heat the as-cast magnesium alloy at 380°C for 3 hours, and then extrude it into a thickness of 2 mm and a thickness of 120 mm. Wide magnesium alloy sheet (extrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com