A method of weakening the texture of zirconium alloy plate through phase change treatment

A technology of phase change treatment and zirconium alloy, which is applied in the field of zirconium alloy processing to achieve the effect of good repeatability, simple equipment and reliable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

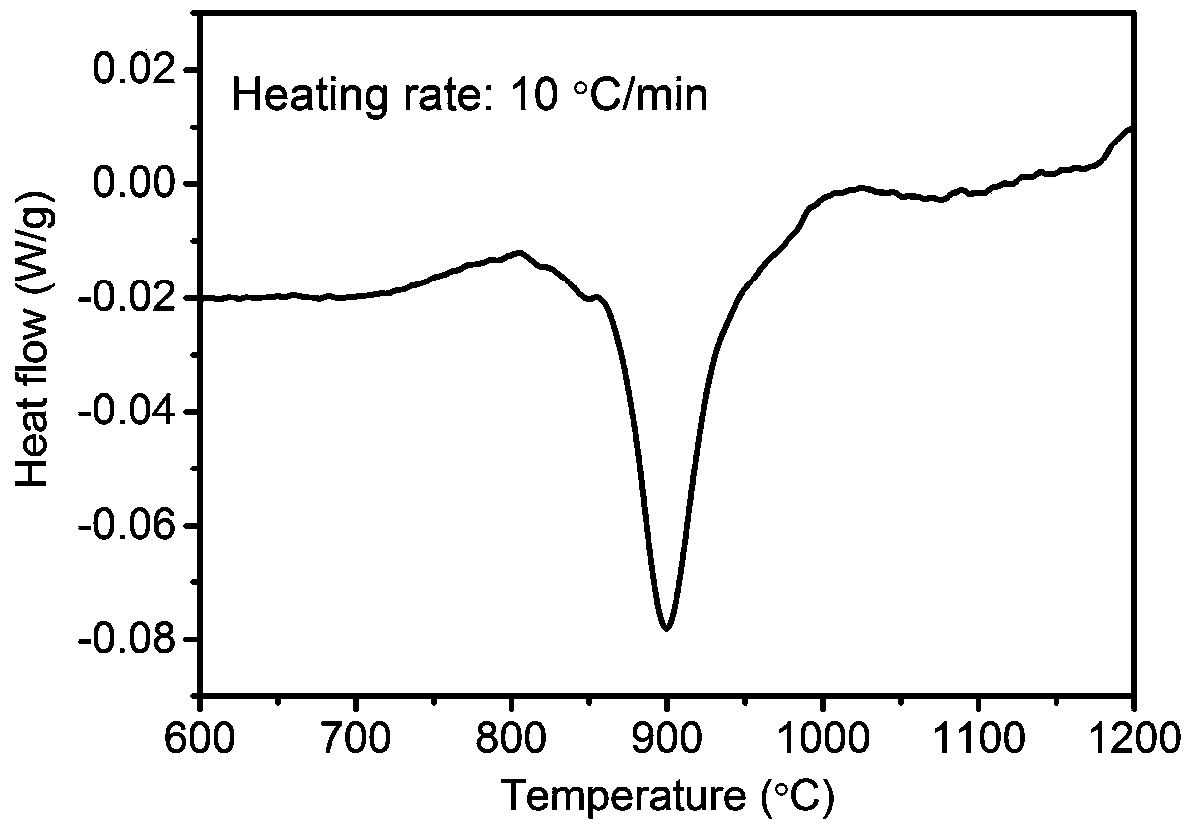

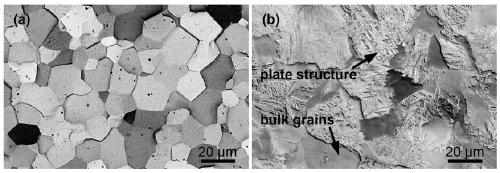

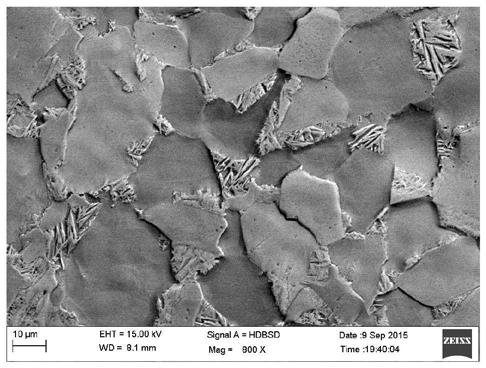

Method used

Image

Examples

Embodiment 1

[0028] Use 800#, 1200#, 2000# and 4000# sandpaper to polish each surface of the above-mentioned Zr702 zirconium alloy plate brightly, and then immerse the sample as a whole in a solution composed of 45% nitric acid, 45% hydrofluoric acid and 10% distilled water (volume fraction). Corrosion mixed solution, shake the solution continuously at the same time, take out the sample after corrosion for 10s, wash the surface of the sample with water and absolute ethanol in sequence, and finally dry the surface until there is no trace of water stain on the surface of the sample.

[0029] Vacuum-seal the sample after surface cleaning in a quartz glass tube, and the vacuum degree in the quartz tube during the sealing process is P=2×10 -3 Pa, to ensure that no reactions such as oxidation and hydrogen absorption occur on the surface of the sample during the subsequent high-temperature heat treatment.

[0030] Put the vacuum-sealed sample into a box-type heat treatment furnace heated to 950°...

Embodiment 2

[0033] Use 800#, 1200#, 2000# and 4000# sandpaper to polish each surface of the above-mentioned Zr702 zirconium alloy plate brightly, and then immerse the sample as a whole in a solution composed of 45% nitric acid, 45% hydrofluoric acid and 10% distilled water (volume fraction). Corrosion mixed solution, shake the solution continuously at the same time, take out the sample after corrosion for 10s, wash the surface of the sample with water and absolute ethanol in sequence, and finally dry the surface until there is no trace of water stain on the surface of the sample.

[0034] Vacuum-seal the sample after surface cleaning in a quartz glass tube, and the vacuum degree in the quartz tube during the sealing process is P=2×10 -3 Pa, to ensure that no reactions such as oxidation and hydrogen absorption occur on the surface of the sample during the subsequent high-temperature heat treatment.

[0035] The vacuum-sealed sample was placed in a box-type heat treatment furnace heated to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com