Hybrid power system for recovering potential energy of movable arm of excavating machine

A technology of hybrid power system and potential energy recovery, which is applied in the direction of mechanically driven excavators/dredgers, etc., which can solve the problems of accumulator oil cannot flow out, accumulators are bulky, and use many components, and meet the specifications and occupancy Reduced space, high energy recovery rate, and easy centralized control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

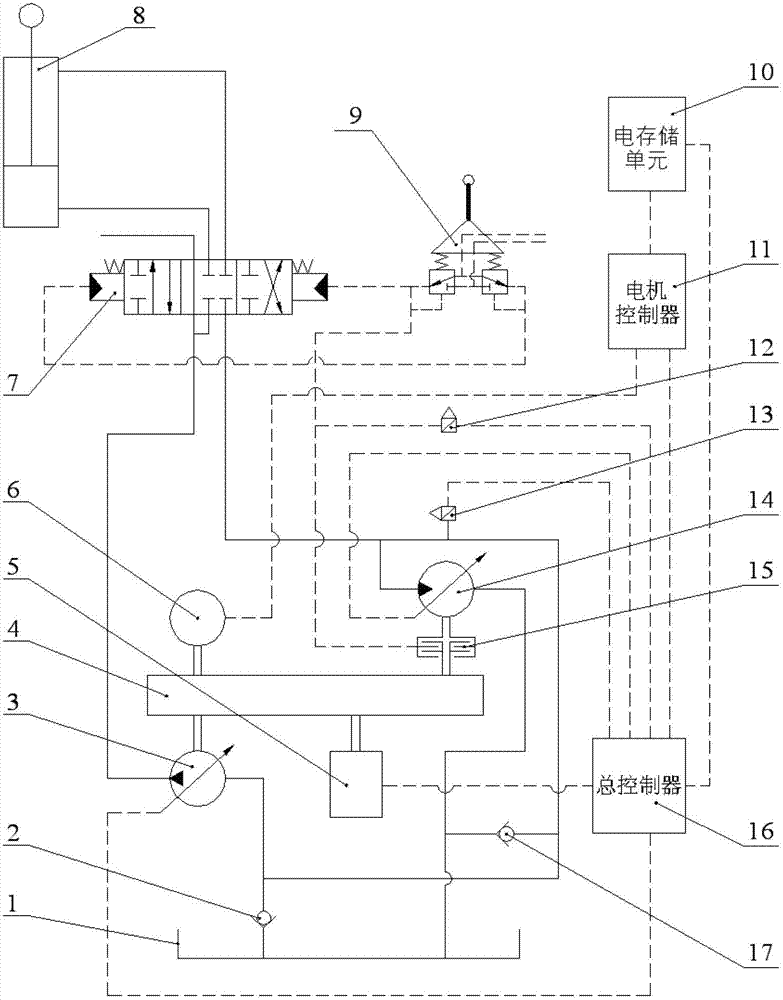

[0029] like figure 1 As shown, the potential energy recovery hybrid power system of the excavator arm of the present invention includes a fuel tank 1, a main variable pump 3, an engine 5, a main reversing valve 7, a boom cylinder 8, a pilot control valve 9, a one-way valve I2, a transfer Box 4, motor 6, electric storage unit 10, motor controller 11, pressure sensor I12, pressure sensor II13, hydraulic motor 14, clutch 15, master controller 16, one-way valve II17;

[0030] The one-way valve I2 is located on the oil path from the main variable pump 3 to the fuel tank 1, that is, the outlet of the one-way valve I2 is connected to the main variable pump 3, and the inlet is connected to the fuel tank 1;

[0031] The transfer case 4 is respectively connected with the engine 5, the motor 6, one end of the clutch 15, and the main variable pump 3 to form a linkage mechanism; the hydraulic motor 14 is connected with the other end of the clutch 15;

[0032] The P port of the main revers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com