Outburst prevention track drilling machine for laneway excavation

A kind of crawler and outburst prevention technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of difficult and unsatisfactory moving and relocation, and achieve the effects of flexible operation, reasonable structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

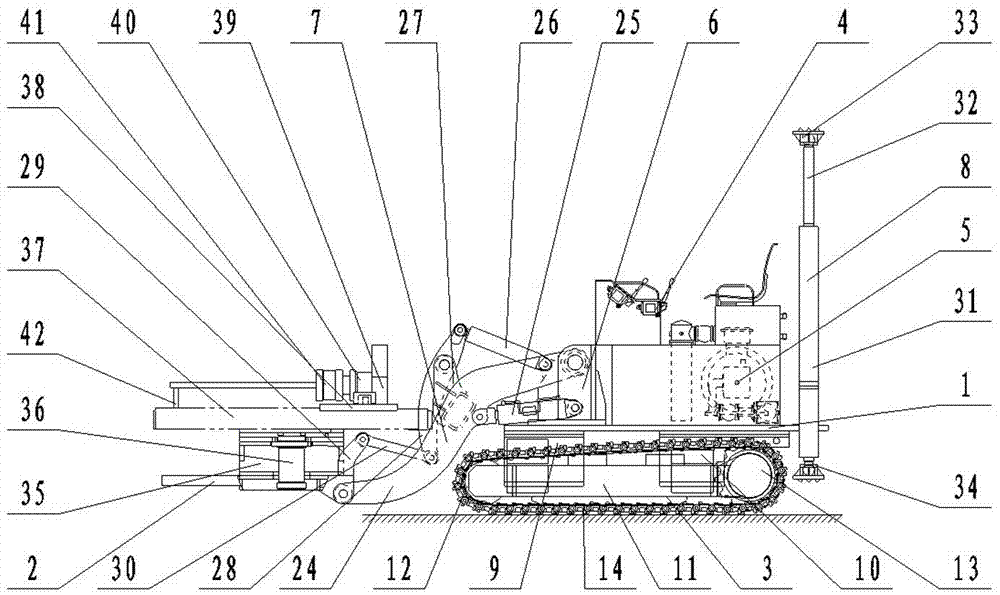

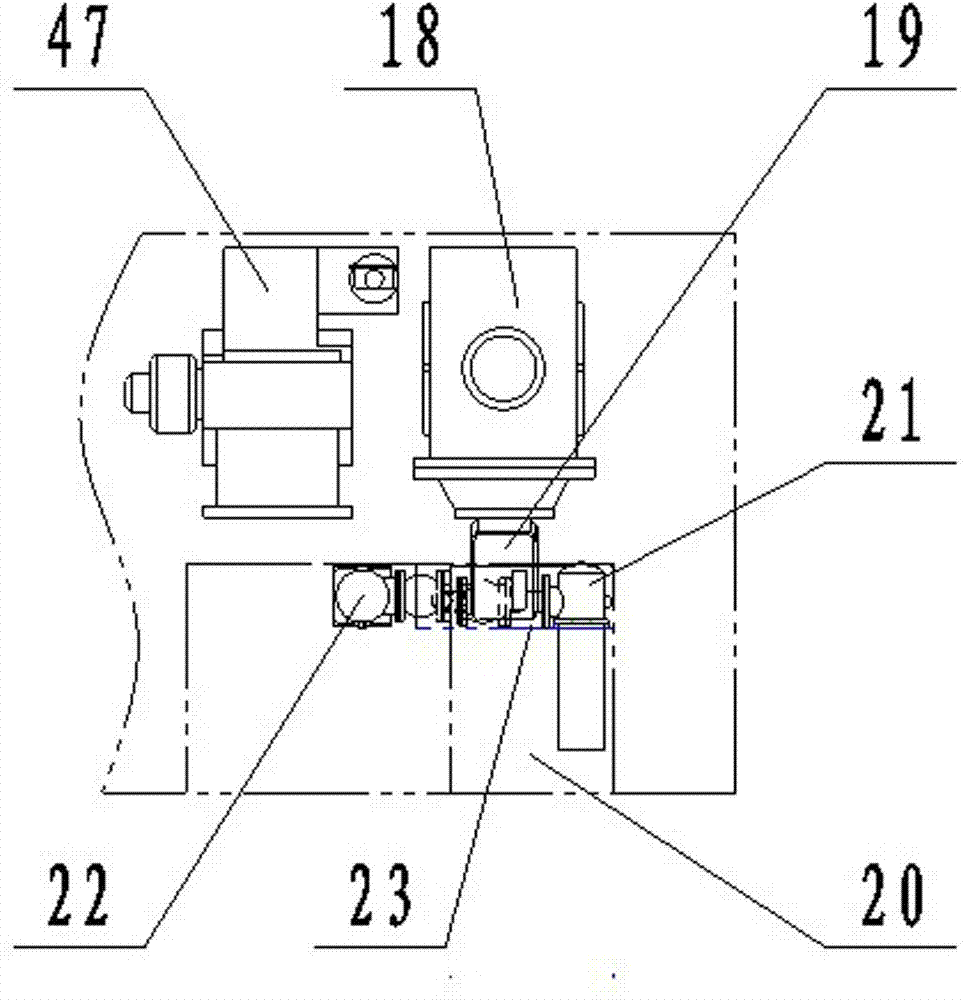

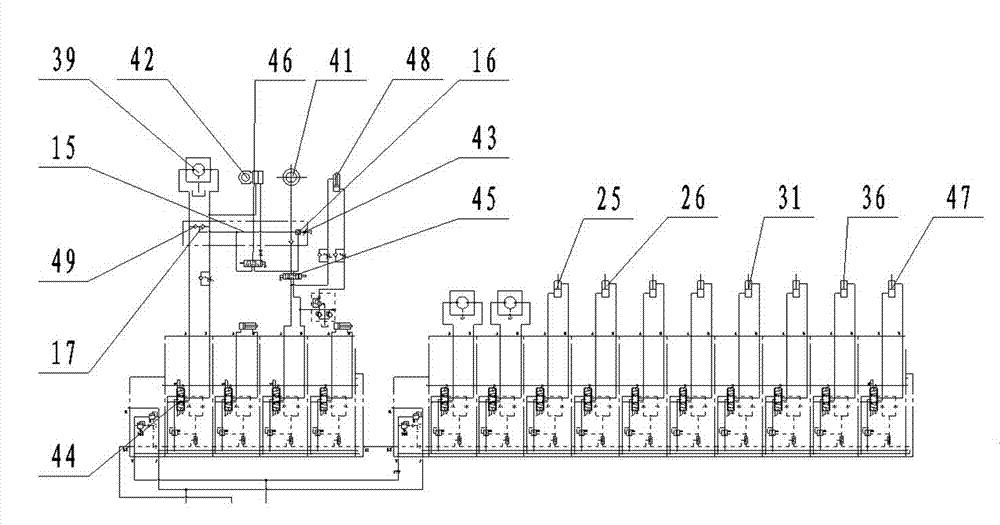

[0020] The outburst prevention crawler drilling rig for excavating roadways includes a body platform 1 and an elevating platform 2 located in front of it, a traveling mechanism 3 is arranged below the body platform 1, and a control mechanism 4, a mud pump 47, a hydraulic mechanism 5, and a hydraulic mechanism are arranged above the body platform 1. system, the front end of the body platform 1 is provided with a fixed seat 6, a lifting mechanism 7 connected with the two is provided between the fixed seat 6 and the lifting platform 2, and a support mechanism 8 is provided at the rear end of the body platform 1;

[0021] The traveling mechanism 3 includes a front connecting beam 9 and a rear connecting beam 10 fixed below the body platform 1, and a crawler frame 11 is fixed between the front connecting beam 9 and the rear connecting beam 10, and front sprockets are arranged at the front and rear ends of the crawler frame 11. 12 and the rear sprocket 13, the front sprocket 12 slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com