Temperature real-time detector for flue-cured tobaccos

A technology of flue-cured tobacco leaves and detectors, which is applied in the directions of instruments, thermometers, measuring devices, etc., can solve the problems of high labor intensity, high risks, and mistakes in baking, so as to improve the efficiency and quality of flue-cured tobacco, reduce labor intensity, and improve operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

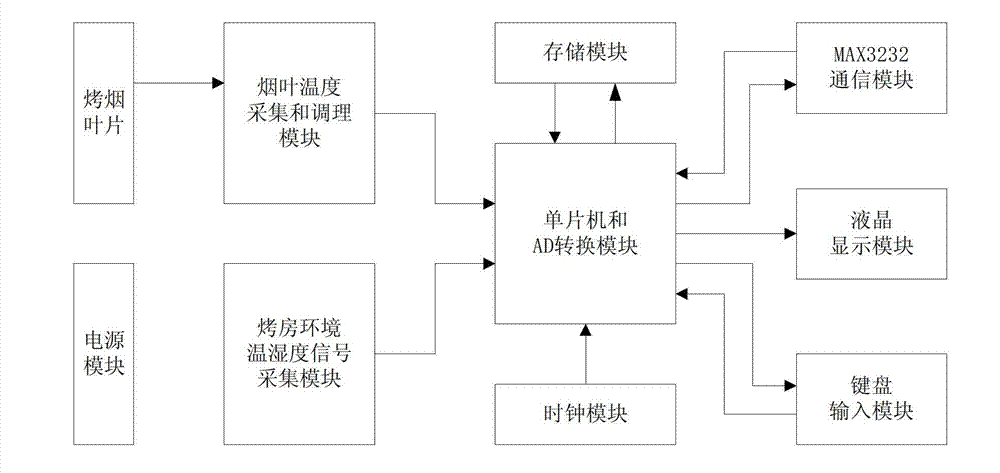

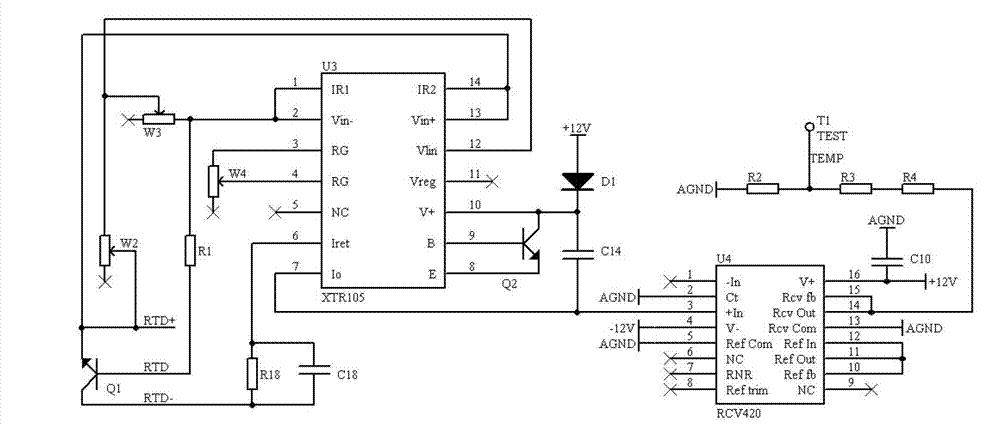

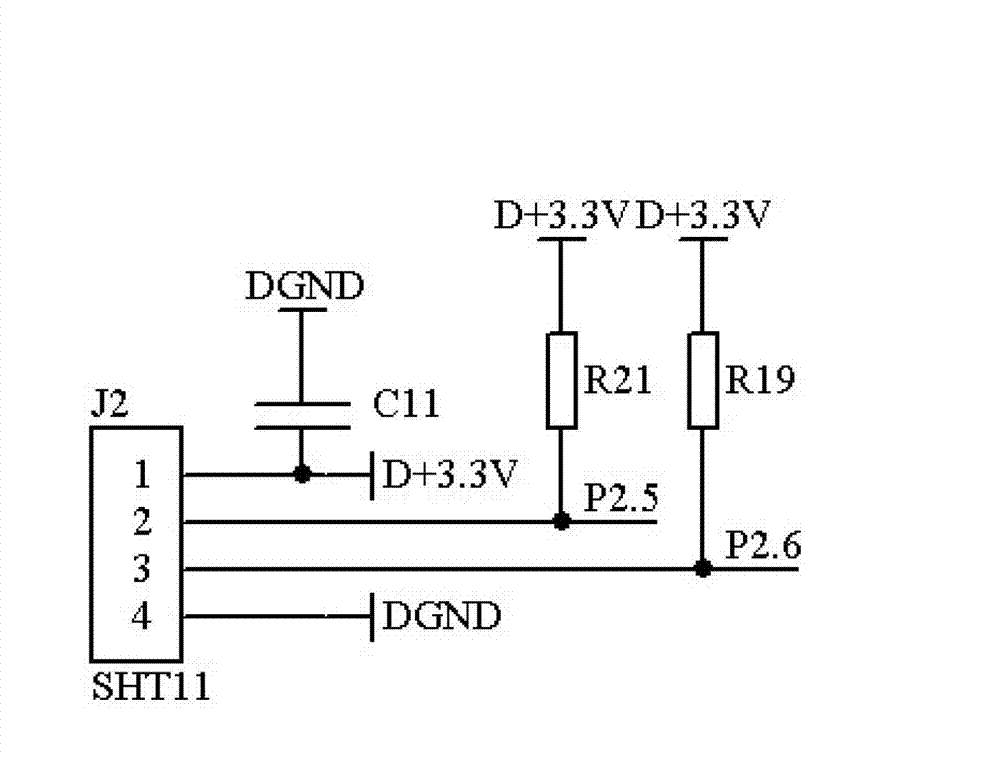

[0040] The invention uses a platinum thermal resistance to measure the surface temperature of the tobacco leaves, and simultaneously uses an integrated digital temperature and humidity sensor SHT11 to monitor the temperature and humidity of the barn environment. The platinum thermal resistance is used to collect the temperature signal of the tobacco leaf surface, and the SHT11 collects the temperature and humidity signal of the barn environment, and the obtained signals are respectively converted and processed through the measurement and control circuit with the single-chip microcomputer as the core, so as to realize the accurate measurement of the temperature of the tobacco leaf and the temperature and humidity of the barn environment , display, storage, communication and other functions.

[0041] like figure 1 As shown, the flue-cured tobacco leaf temperature real-time d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com