Waveguide filter with welding structure

A waveguide filter and welding structure technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems of surface flatness, tolerance difference of finish, high cost and scrap rate, poor contact between cavity and cover plate, etc. , to achieve good consistency, reduce signal leakage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

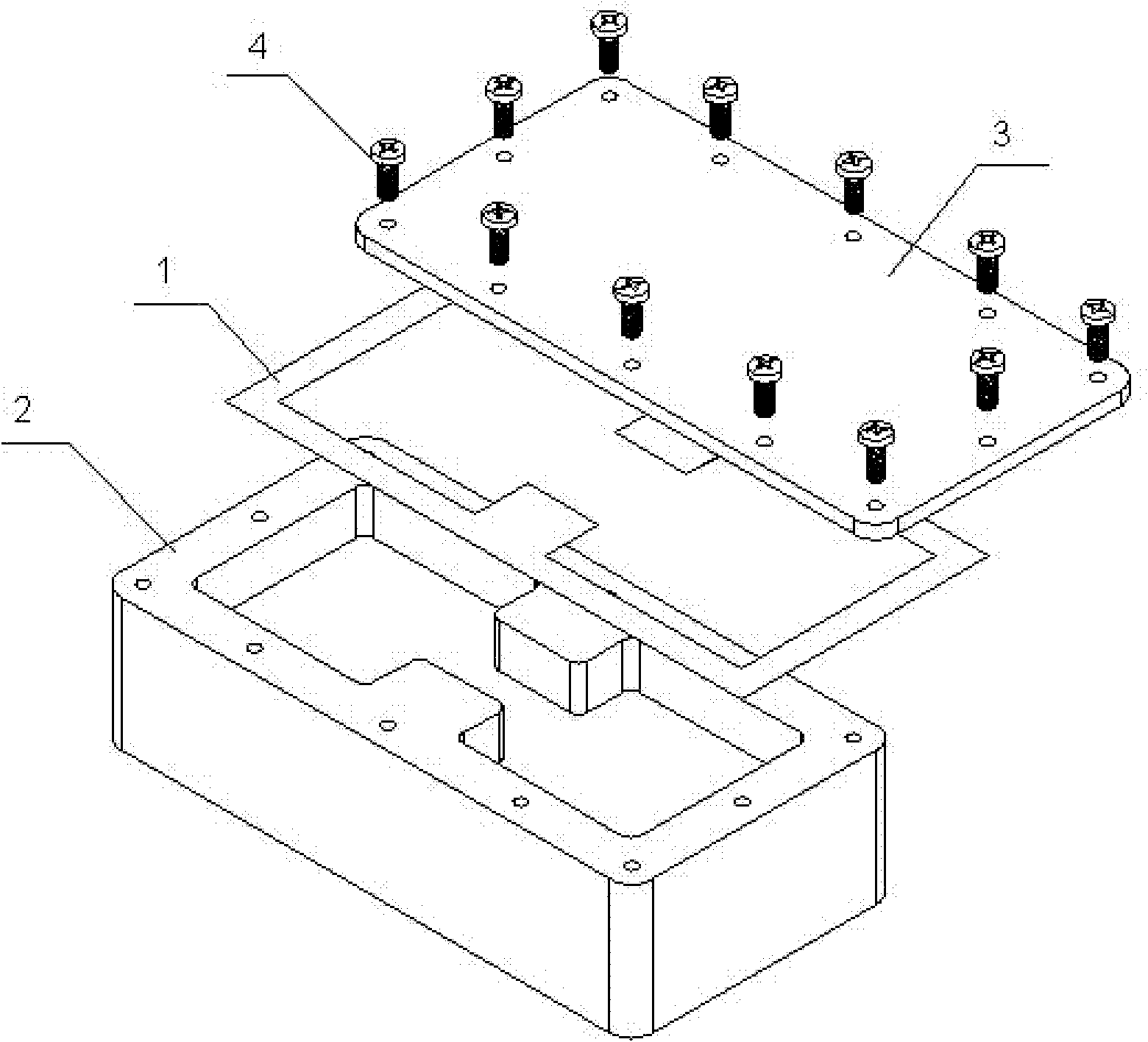

[0020] Such as figure 1 As shown, a waveguide filter with a welded structure, the cover plate 3 is set above the cavity 2, and a layer of solder layer 1 with the same shape as the upper surface of the cavity 2 is provided between the two, and the fastening screw 4 passes through The solder layer 1 fixes the cover plate 3 and the cavity 2 so that they are closely connected. The solder layer 1 is a solder paste composed of flux and solder powder and soldered by reflow welding, so that the cavity 2 and the cover plate 3 are in close contact, and the number of fastening screws 4 can also be reduced. This welding structure can effectively reduce signal leakage even if the processing precision of the cover plate and the cavity is not high, so that the product performance is reliable and the cost is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com