Horizontal pneumatic pressing machine and press-fit method for cable assembly

A cable assembly and press technology, applied in the field of electronic information, can solve the problems of special parts that cannot be processed, poor processing quality consistency, inconvenient operation, etc., and achieve the effect of perfect man-machine integration, low manufacturing cost, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

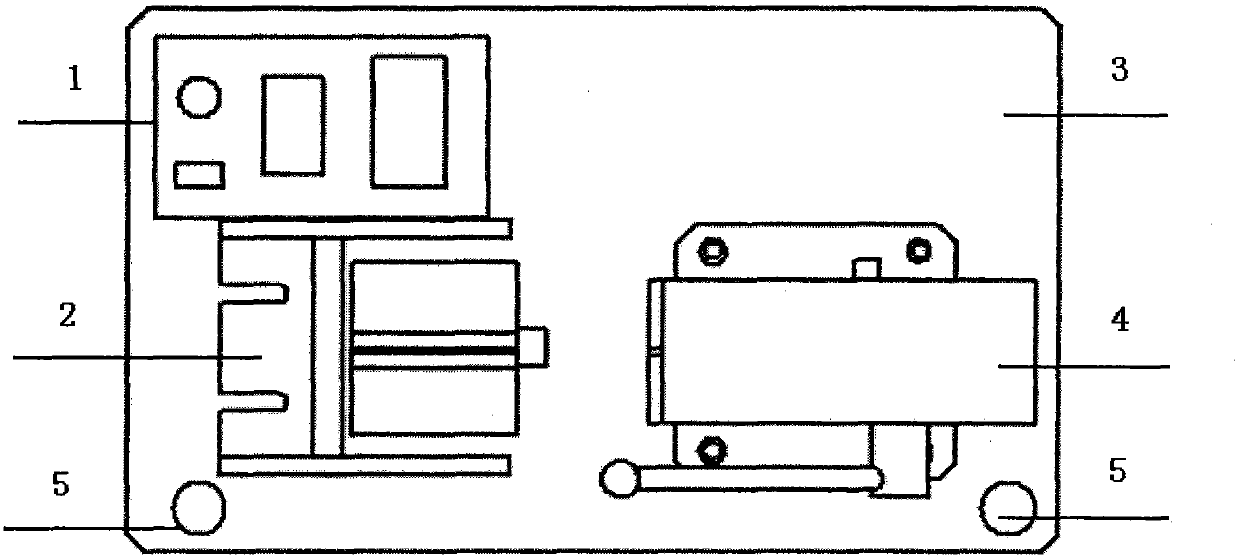

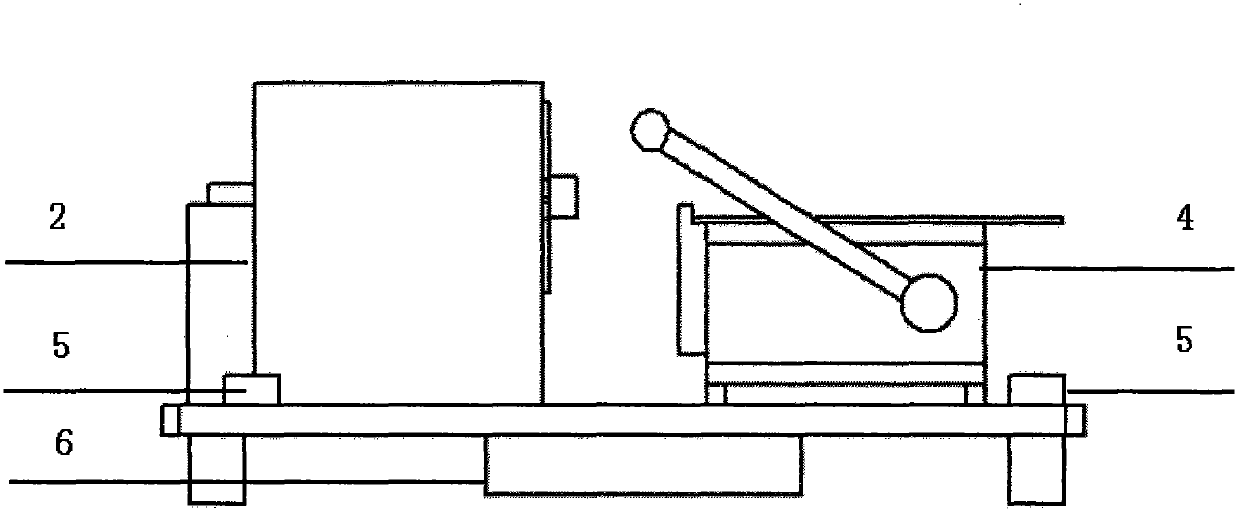

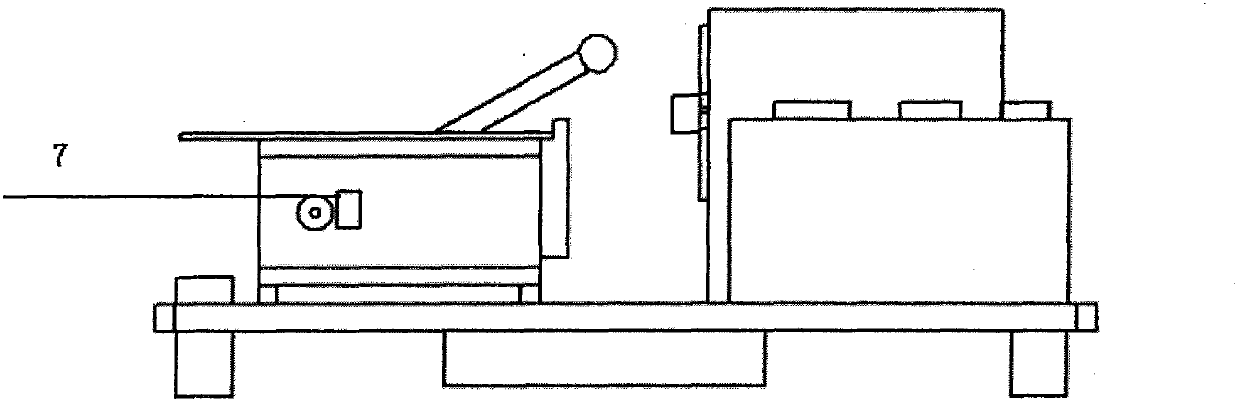

[0039] The present invention is a horizontal pneumatic press for a cable assembly, comprising: a solenoid valve, a table with a support seat, a pressure mechanism installed on the table, a positioning mechanism and a start switch, and the solenoid valve is installed on a table with a support seat Under the table, the solenoid valve is connected with the electrical signal of the pressure mechanism, see figure 1, The cable assembly horizontal pneumatic press also includes a PLC electrical control mechanism 1 and a sensing mechanism 7, the PLC electrical control mechanism 1 and the start switch 5, and the PLC electrical control mechanism 1 and the solenoid valve 6 are electrically connected. The sensing mechanism is installed on the side of the positioning mechanism. The sensing mechanism is electrically connected with the PLC electrical control mechanism 1 and the solenoid valve 6. When the human hand pulls the wrench 12 down to the 90° position, the sensing mechanism 7 senses th...

Embodiment 2

[0046] The cable assembly horizontal pneumatic press is the same as that in Embodiment 1. The present invention is also a cable assembly press-fitting method, which is characterized in that: the cable assembly horizontal pneumatic press according to claims 1-4, the cable assembly press-fit operation The process includes:

[0047] 1. Turn on the power switch 21 of the press, and the red power indicator light 22 is on; input the preset parameters through the display screen and keyboard of the PLC electrical control mechanism 1, and the preset parameters include pressure preset, pressure holding time preset, counter 23 reset. For different cable assemblies, the present invention can preset different pressure-holding times. The preset pressure-holding time for cable assemblies with a small press-fitting amount is shorter, and the preset pressure-holding time for cable assemblies with a larger press-fitting amount is shorter. long. The preset holding time can be adjusted accordin...

Embodiment 3

[0058] The cable assembly horizontal pneumatic press and the cable assembly press-fitting method are the same as those in Embodiment 1-2. The present invention will be further described in detail below with reference to the accompanying drawings and specific structural mechanisms.

[0059] The main structure of the cable assembly horizontal pneumatic press of the present invention is divided into seven parts, see figure 1 : Pressure mechanism, positioning mechanism, table, solenoid valve, PLC electrical control mechanism, sensing mechanism, start switch.

[0060] The length×width×thickness of the table top 3: 500mm×300mm×10mm is made of national standard 45# steel, the outer surface is treated with light, the edges and corners are blunt and electroplated with nickel.

[0061] Wherein the positioning mechanism includes: base plate B, fuselage, main shaft, return spring, cam, connecting rod, wrench, positioning plate, slide plate and totally nine parts.

[0062] The components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com