All-solid-state heterojunction solar cell

A technology of solar cells and sunlight, applied in the field of dye-sensitized solar cells, to achieve the effects of easy operation, ease of process conditions, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

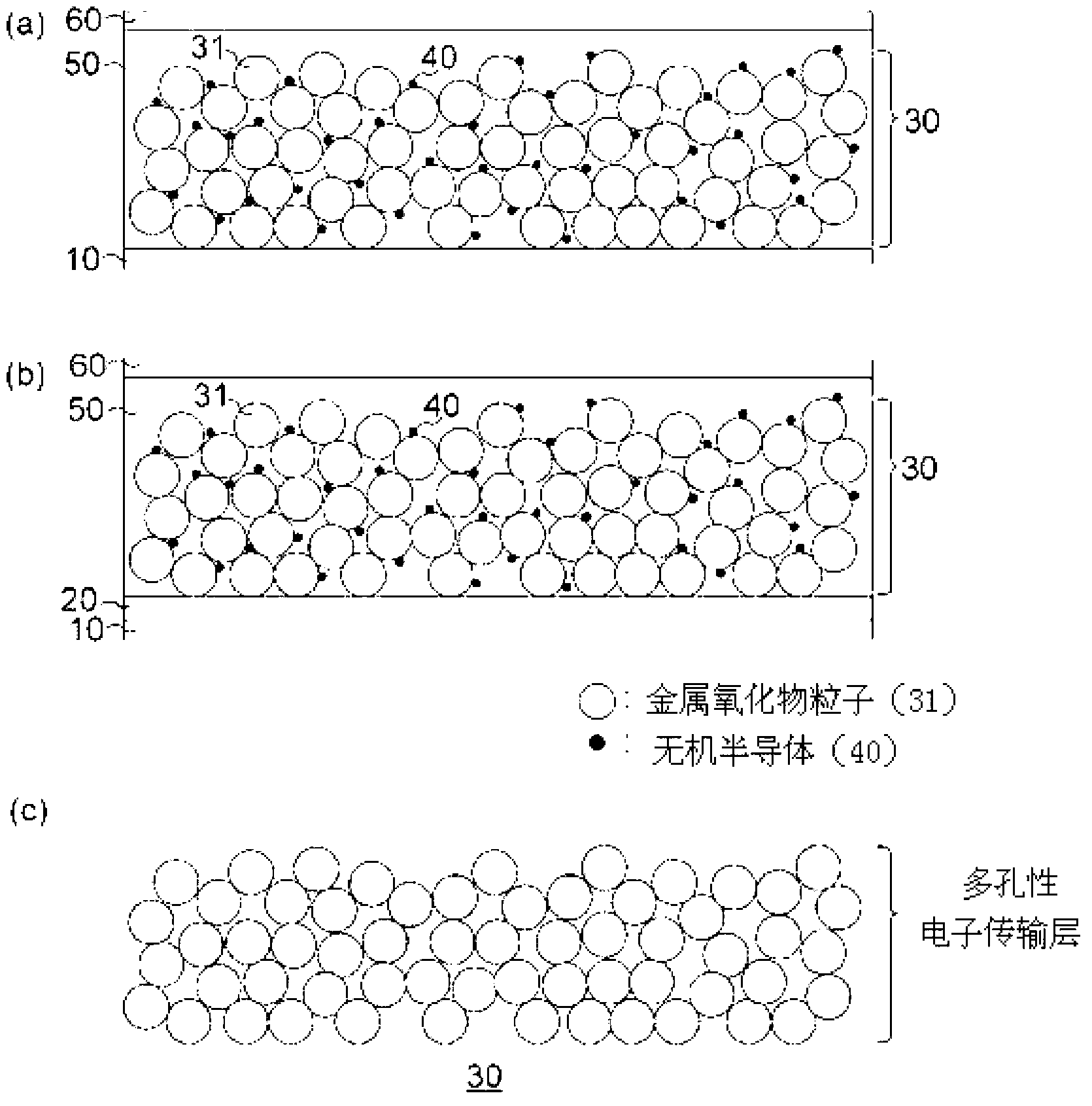

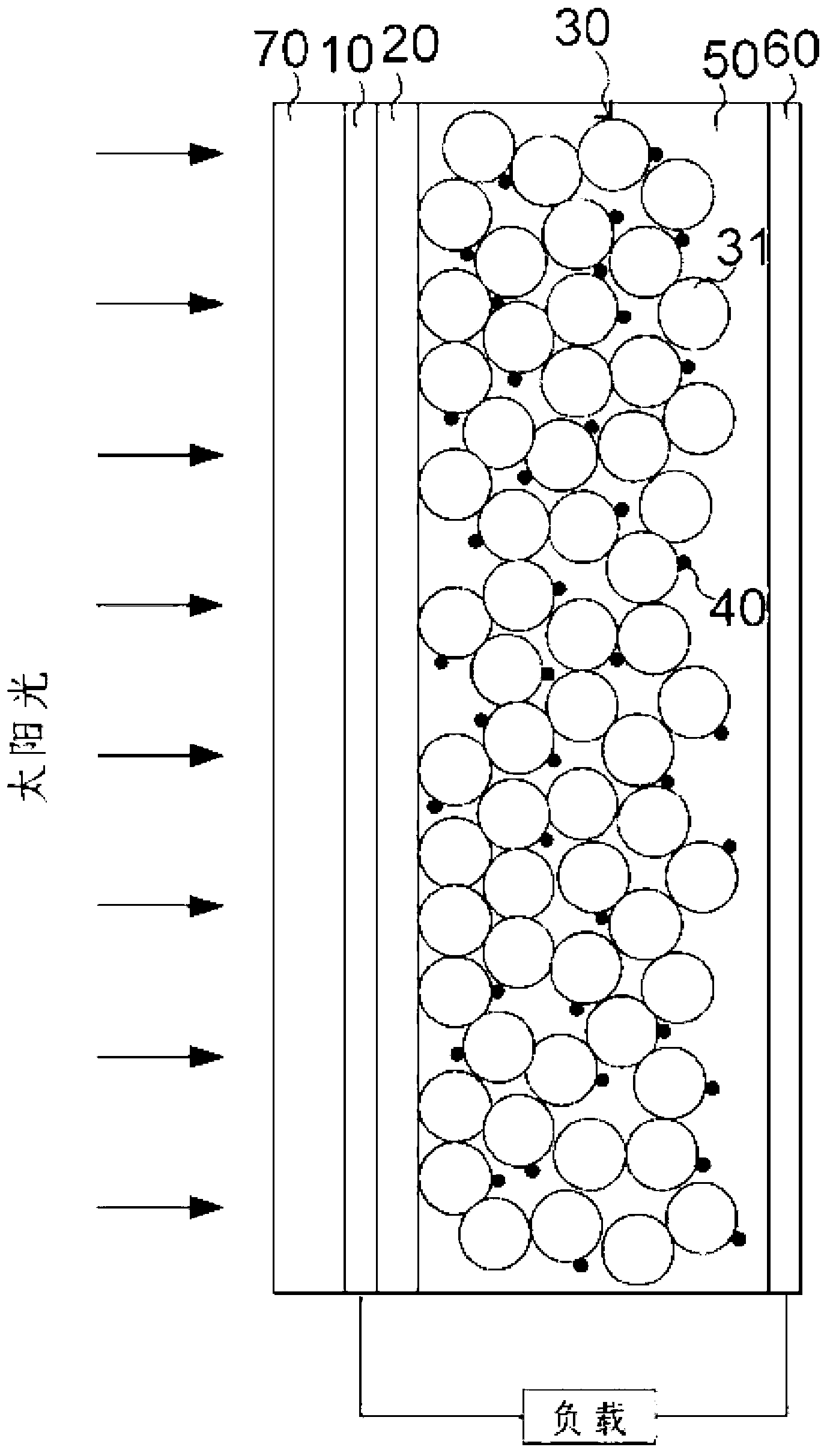

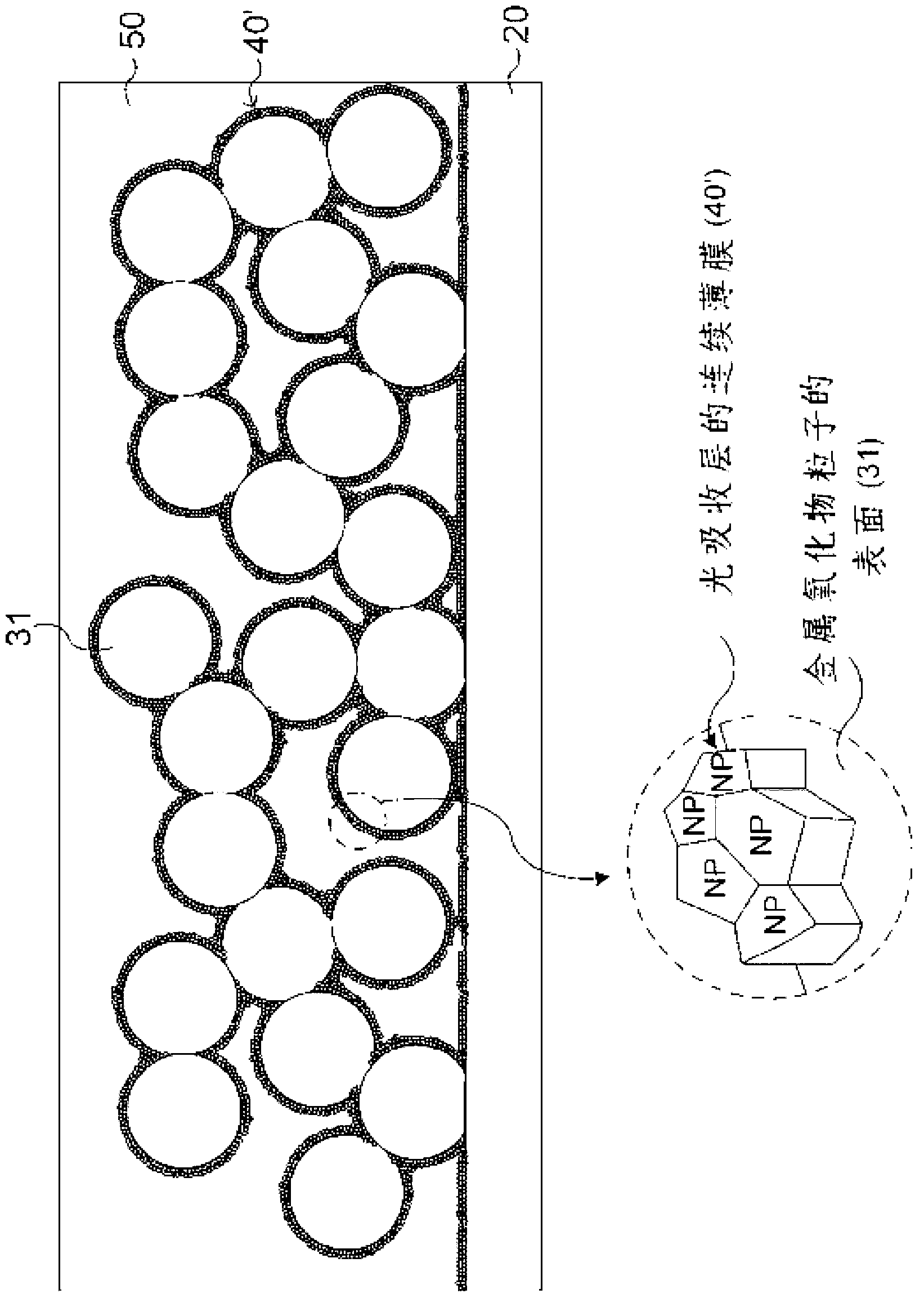

Method used

Image

Examples

preparation example 1)

[0142] A glass substrate coated with fluorine-containing tin dioxide (first electrode) (FTO; F-doped (doped) SnO 2 , 8ohms / sq, Pilkington double-sided grinding method, hereinafter referred to as FTO substrate) after truncated to a size of 25×25mm, and Figure 5 The ends are similarly etched to remove part of the FTO.

[0143] As a recombination prevention film on the truncated and partially etched FTO substrate, a dense structure of TiO with a thickness of about 50 nm was prepared by spray pyrolysis 2 film. The above spray pyrolysis is carried out by using tetraacetylacetonate titanium TAA (Titanium acetylacetonate): EtOH (1:9v / v%) solution, placed on the FTO substrate placed on a hot plate maintained at 450 ° C, using repeated spraying for 3 seconds The method of resting for another 10 seconds adjusted the thickness.

[0144] TiO with an average particle size of 60nm 2 powder (as TiO 2As a benchmark, an aqueous solution in which 1% by weight of titanium peroxide complex ...

preparation example 2)

[0150] A glass substrate coated with fluorine-containing tin dioxide (first electrode) (FTO; F-doped (doped) SnO 2 , 8ohms / sq, Pilkington double-sided grinding method, the following FTO substrate) after truncating to a size of 25×25mm, and Figure 5 Similarly, etch the end to remove part of the FTO.

[0151] As a recombination prevention film on the truncated and partially etched FTO substrate, a dense structure of TiO with a thickness of about 50 nm was prepared by spray pyrolysis 2 film. The above spray thermal decomposition is carried out by using titanium tetraacetylacetonate TAA: EtOH (1:9v / v%) solution, on the FTO substrate placed on a hot plate maintained at 450 ℃, using repeated spraying for 3 seconds and then standing still for 10 seconds method adjusted the thickness.

[0152] TiO with an average particle size of 60nm 2 powder (as TiO 2 As a benchmark, an aqueous solution in which 1% by weight of titanium peroxide complex was dissolved was heat-treated at 250°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com