Breast washing solution for milking cow and preparation method thereof

An emulsion and cow technology, applied in the field of washing, can solve the problems of entering and not completely removing the dirt and bacteria on the udder of cows, damaging the lactation system of cows, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

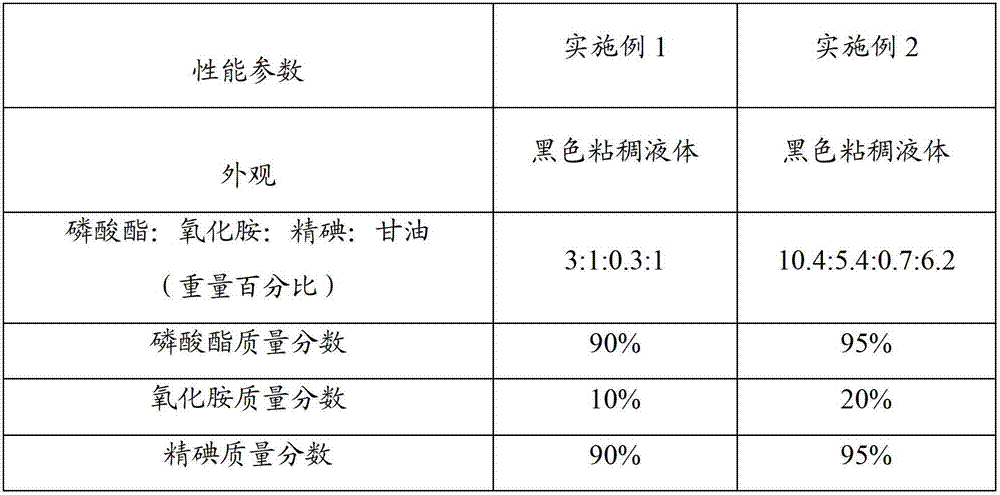

Embodiment 1

[0031] Preparation of components in the recipe:

[0032] (1) Phosphate:

[0033] Take 3 kg of dodecyl phosphate solution with a mass fraction of 90%, and place it in a clean container for use.

[0034] (2) Glycerin:

[0035] Take 1 kg of glycerol solution with a mass fraction of 90%, and place it in a clean container for use.

[0036] (3) Amine oxide:

[0037] Take 10 kg of octadecyl dihydroxyethyl amine oxide solution with a mass fraction of 10%, and place it in a clean container for use.

[0038] (4) Refined iodine:

[0039] Take 0.3 kg of solid iodine with a mass fraction of 90%, and place it in a clean container for later use.

[0040] To prepare the cow wash lotion:

[0041] (1) Prepare 3 kg of dodecyl phosphate ester solution with a mass fraction of 90%, 10 kg of octadecyl dihydroxyethyl amine oxide solution with a mass fraction of 10%, and 90% 0.3 kg of solid iodine is poured into a clean reactor.

[0042] (2) Heating temperature to 40°C.

[0043] (3) Turn on t...

Embodiment 2

[0049] (1) Phosphate:

[0050] Take 10 kg of nonylphenol polyoxyethylene ether phosphate ester solution with a mass fraction of 95%, and place it in a clean container for use.

[0051] (2) Glycerin:

[0052] Take 6 kg of glycerol solution with a mass fraction of 95%, and place it in a clean container for use.

[0053] (3) Amine oxide:

[0054] Take 25 kg of cetyl dimethyl amine oxide solution with a mass fraction of 20%, and place it in a clean container for use.

[0055] (4) Refined iodine:

[0056] Take 0.7 kg of solid iodine with a mass fraction of 95%, and place it in a clean container for later use.

[0057] To prepare the cow wash lotion:

[0058] (1) 10 kg of nonylphenol polyoxyethylene ether phosphate solution with a mass fraction of 95% prepared above, 25 kg of cetyldimethylamine oxide solution with a mass fraction of 20%, and a mass fraction of 95 % solid refined iodine 0.7 kilograms, pour in the clean reactor.

[0059] (2) Heating temperature to 60°C.

[006...

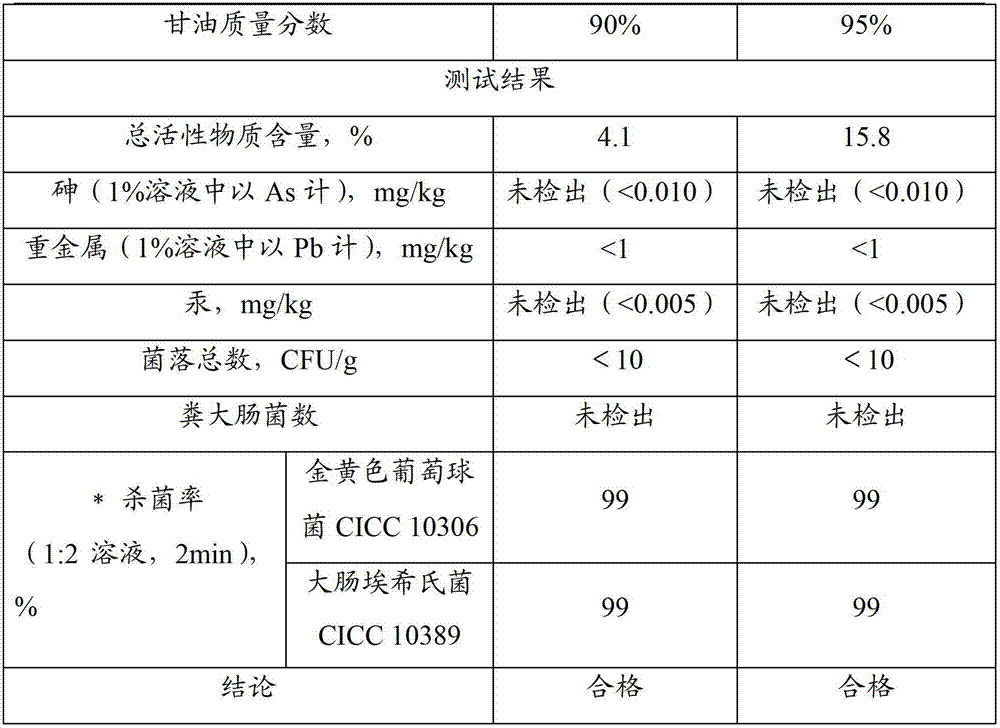

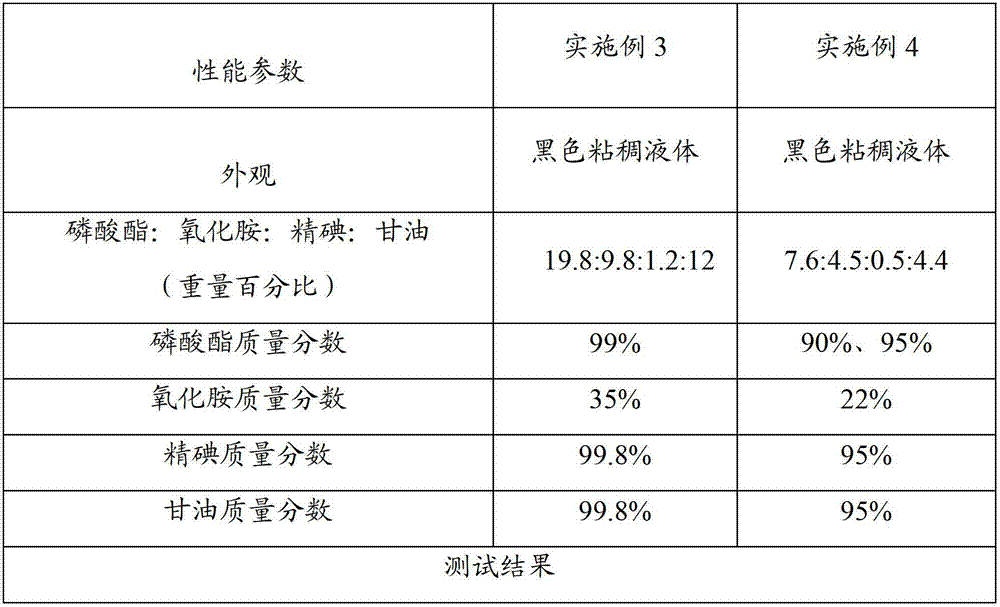

Embodiment 3

[0066] Preparation of components in the recipe:

[0067] (1) Phosphate:

[0068] Weigh 20 kg of polymeric acid ester solution with a mass fraction of 99%, and place it in a clean container for use.

[0069] (2) Glycerin:

[0070] Weigh 12 kg of glycerol solution with a mass fraction of 99.8%, and place it in a clean container.

[0071] (3) Amine oxide:

[0072] Weigh 28 kilograms of octadecamidopropylamine oxide solution with a mass fraction of 35%, and place it in a clean container.

[0073] (4) Refined iodine:

[0074] Weigh 1.2 kg of solid iodine with a mass fraction of 99.8%, and place it in a clean container.

[0075] To prepare the cow wash lotion:

[0076] (1) 20 kilograms of the polymeric acid ester solution with a mass fraction of 99%, 28 kilograms of an octadecamidopropylamine oxide solution with a mass fraction of 35%, and solid refined iodine with a mass fraction of 99.8% 1.2 kg, and pour them into the inner layer of a clean reactor.

[0077] (2) Heating temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com