Short-flow processing technology of ferrule roughcast used for turntable bearing

A technology of turntable bearings and processing technology, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of low production efficiency, cumbersome processing methods, high production costs, etc., and achieve the effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The processing technology of the present invention is described in conjunction with the specific examples given, but does not constitute any limitation to the present invention.

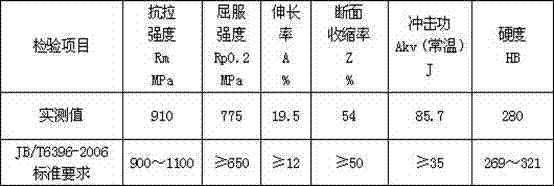

[0010] The bearing ring described in the invention is a short-process processing process of the ring ring blank for the slewing bearing with an outer diameter within the range of 500 mm to 1500 mm. The process includes: smelting→casting into a circular casting→cutting the riser→heating the ring Shaped castings→rolling and expanding into annular ferrule blanks, and then normalizing and quenching and tempering heat treatment on the rolled and expanded annular ferrule blanks.

[0011] Take the bearing model 013.30.1220.04 as an example to illustrate. Its process steps are:

[0012] Smelting: use electric arc furnace to smelt 42CrMo steel according to the conventional process, the chemical composition of molten steel (ZG42CrMo) should meet: C 0.38~0.45, Mn 0.60~1.00, Si 0.30~0.60, Cr 0.80~1.20, M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com