Activated sludge-biofilm reactor and treatment method of organic wastewater

A biofilm reactor, activated sludge technology, applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of long aeration cycle and high energy consumption, and achieve The effect of shortening the microbial denitrification process, saving energy, and increasing the content of easily biodegradable organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

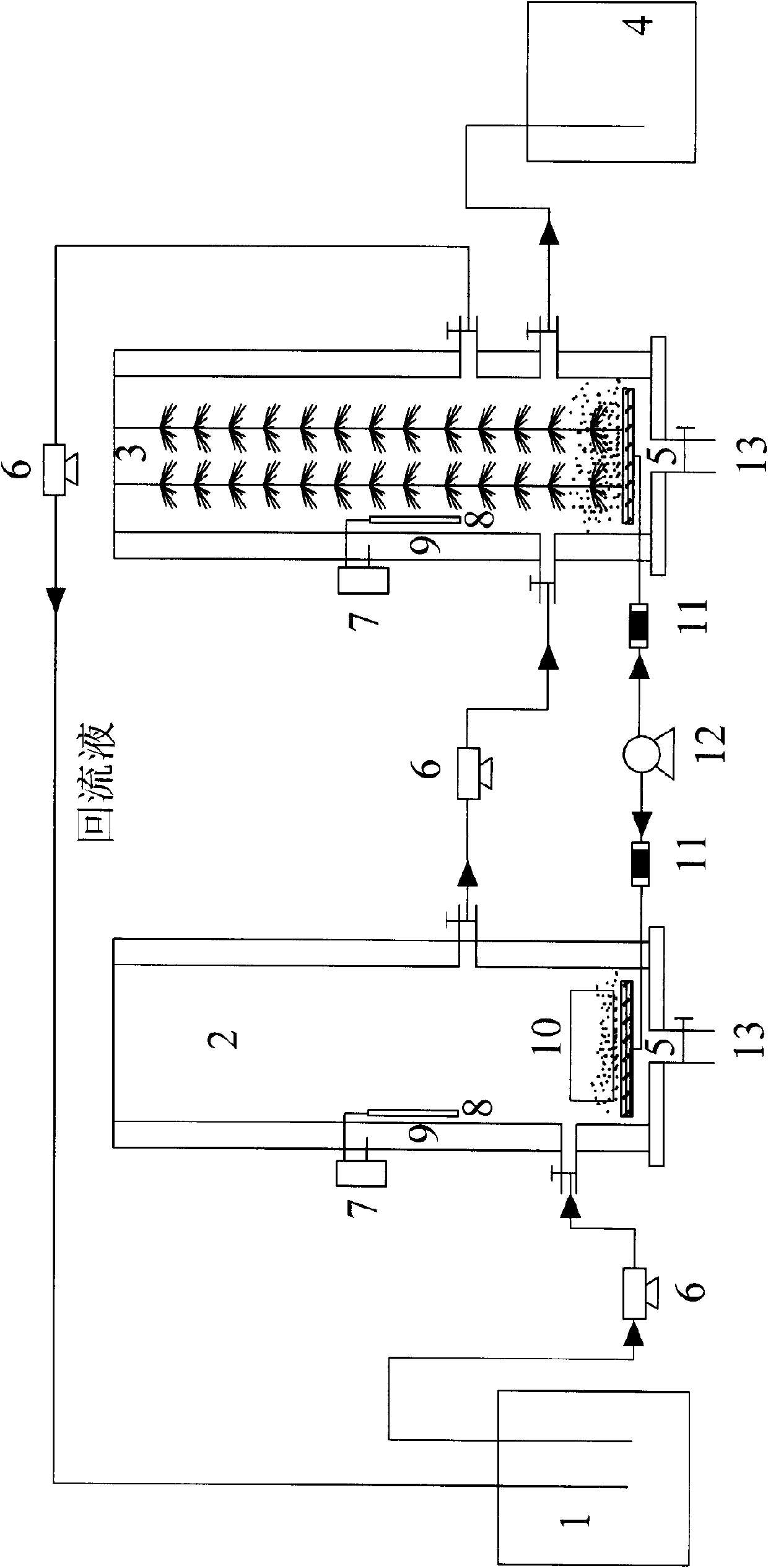

[0040] Please combine figure 1 , The wastewater and the reflux liquid are mixed in the distribution tank 1, and are introduced into the activated sludge reactor 2 under the action of the water pump 6, and the agitator 10 is turned on at the same time, so that the activated sludge and the wastewater are fully mixed, and the first stage anaerobic reaction is carried out. After the wastewater is filled with the activated sludge reactor 2, the water pump 6 is turned off. After 12 hours, the second stage anoxic reaction is started, the nano aerator 12 is turned on, and the aeration plate 5 is aerated under the control of the rotameter 11. After the second stage ends, the third stage of anaerobic reaction starts, which is the same as the first stage.

[0041] After the reaction in the activated sludge reactor is completed, the agitator 10 is turned off, the sludge and water are separated for a period of time after precipitation, and it flows into the aerobic biofilm reactor 3 for reacti...

Embodiment 2

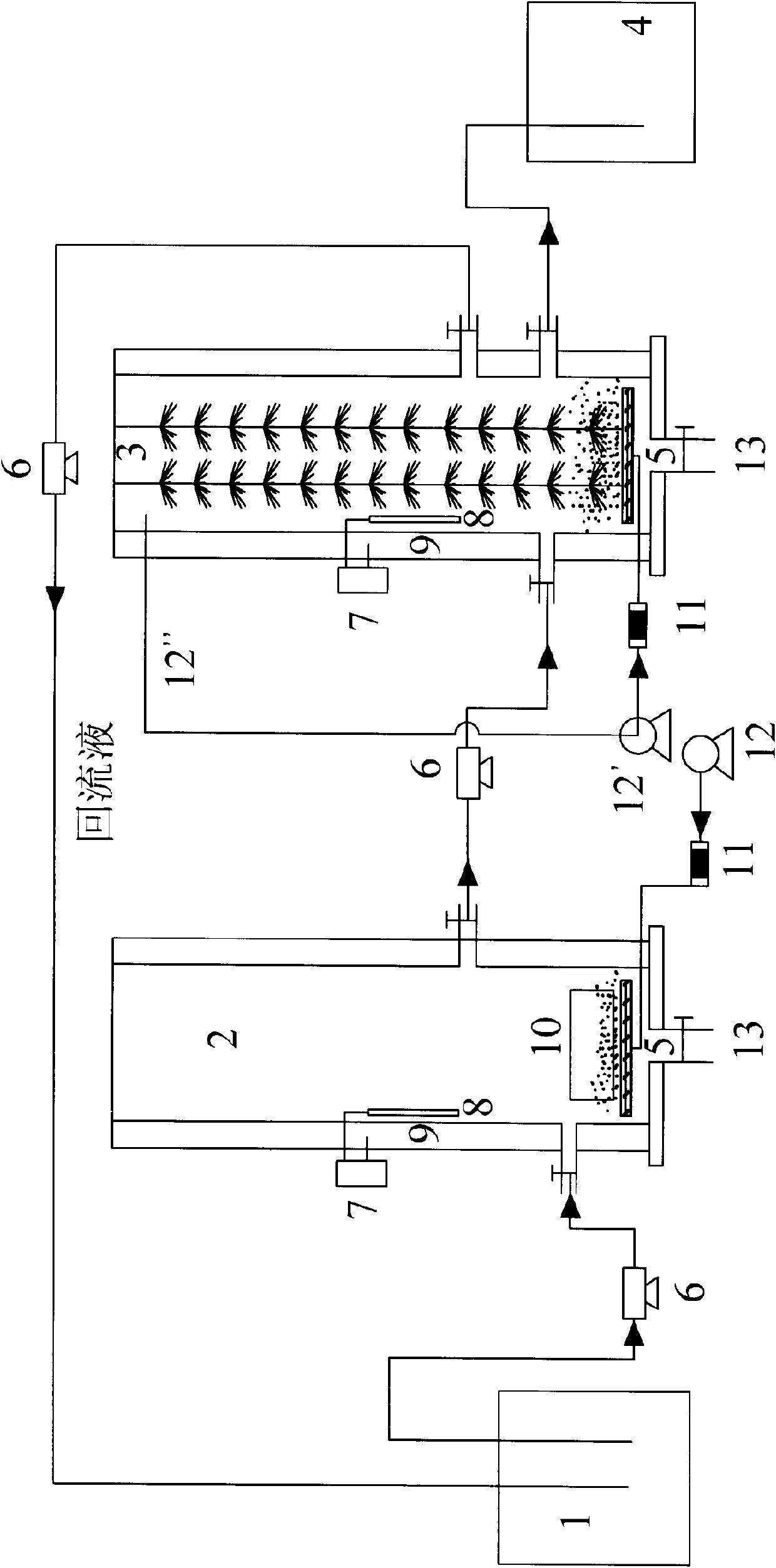

[0051] The activated sludge-biofilm reactor of this embodiment is basically the same as that of Embodiment 1. The difference is that the aerator of the aerobic biofilm reactor 3 of this embodiment is a nano-aerator 12', and is connected to the upper part of the aerobic biofilm reactor 3 through a water inlet pipe 12'.

[0052] The nano-aerator of this embodiment can generate a large number of micro-bubbles. When these nano-bubbles are dissolved in water, the water is milky white, which increases the specific surface area of gas-liquid mass transfer, thereby improving the efficiency of gas-liquid mass transfer. Moreover, the slow rising speed of nanobubbles greatly increases the gas-liquid contact area and contact time, which is beneficial for the bubbles to dissolve in water and increase the concentration of dissolved oxygen in the water. To a certain extent, it overcomes the shortcomings of oxygen insoluble in water. This makes the use of nano-aeration has its own unique adva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com