Bacterial strain for generating anisic acid by converting anethole, and screening method and application of bacterial strain

A screening method, the technology of anisic acid, applied in the field of transforming anethole to produce anisic acid strains and fermenting the field of producing anisic acid, can solve the problems of many by-products, pollute the environment, waste resources, etc., and achieve the effect of optimizing fermentation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Screening of strains

[0029] 5 g of each collected soil sample was weighed and added to the sterilized enrichment medium, and cultured on a shaker at 30° C. at 200 rpm for 72 hours. Transfer the bacterial solution to fresh enrichment culture according to 10% inoculum amount, after three times of concentration gradient enrichment culture of anethole, take 1mL enrichment culture, carry out gradient dilution with sterile water, take 10 -5 、10 -6 and 10 -7 Three concentrations, spread on the minimal medium plate, and incubate upside down at 30°C for 3-5 days. Pick a single colony on the plate, inoculate it into a 10ml basic medium finger flask, add 4g / L anethole, culture on a shaker at 200rpm at 30°C for 48h, and streak on the basic medium plate; repeat several times for purification; Inoculate the purified strain into a finger flask containing 10mL of fermentation medium, add 4g / L anethole, transform at 30°C, shaker at 200rpm for 48h, and perform qualitative analysis o...

Embodiment 2

[0043] Determination of the optimal temperature and transformation time of bacterial strains

[0044] The strain with the preservation number CCTCC NO.M 2012060 was streaked on the seed slant medium, cultured in an incubator at 28°C, and then transferred to a liquid seed medium and cultured on a shaker at 28°C to the logarithmic growth phase. Inoculate 10% of the inoculum into the fermentation medium, carry out fermentation and culture in shaking tables at different temperatures, and extract the fermentation liquid after 24 hours and analyze it by gas chromatography.

[0045] Seed medium (g / L): Tryptone 10g, yeast extract 5g, NaCl 10g, distilled water 1000mL, 121°C, sterilized for 20min; pH 7.0, 30°C, shaker speed 200 rpm, culture time about 12h.

[0046] Fermentation medium (g / L): glucose 20g, peptone 10g, beef extract 2.5g, KH 2 PO 4 1.0g, NaCl 0.5g, MgSO 4 0.5g, FeSO 4 0.01g, anethole 4g / L, distilled water 1000mL; 115°C, sterilize for 20min; pH 7.0, fermentation tempera...

Embodiment 3

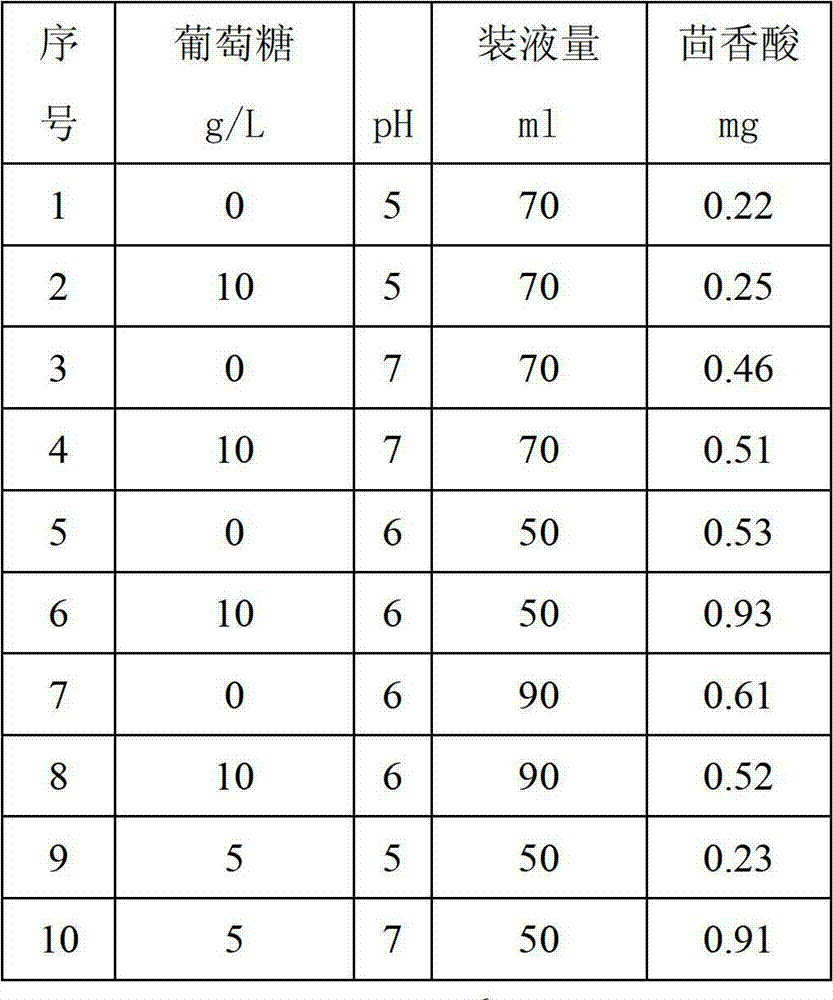

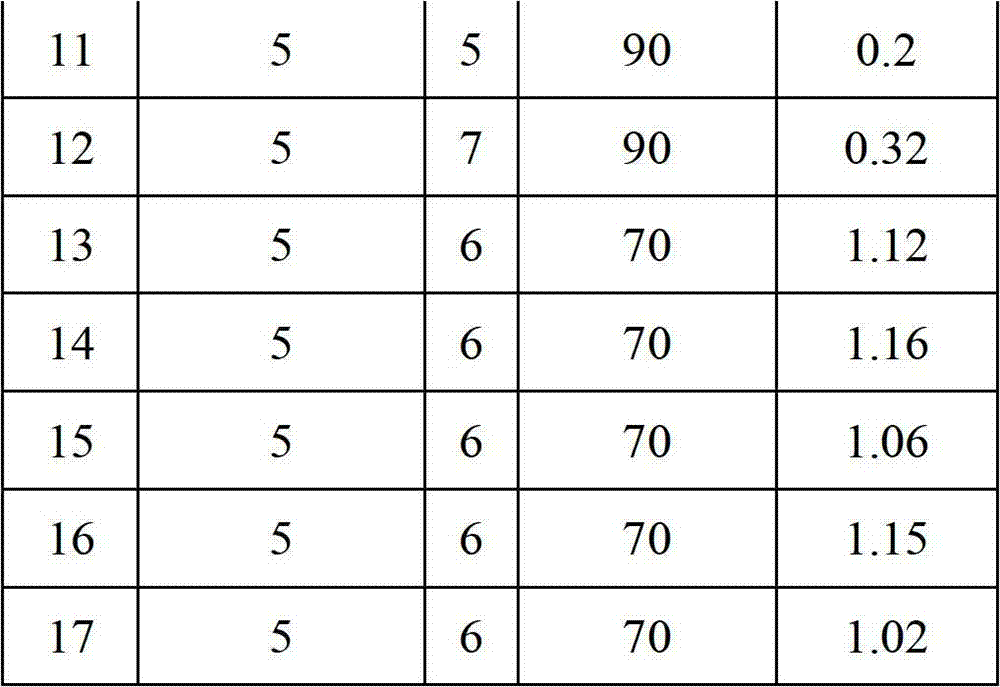

[0061] Optimization of fermentation conditions

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com