Modificator for changing growth morphology of primary austenite of gray cast irons, preparation method and application thereof

A gray cast iron and modifier technology, applied in the field of modifiers, can solve problems such as shrinkage porosity, large shrinkage of molten iron, and poor casting process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] 1. Melting in a 500Kg power frequency melting furnace, thermocouple temperature measurement, molten iron temperature 1530°C, inoculated and deteriorated in the ladle, fully stirred and poured in the resin sand mold for tensile strength measurement and tissue analysis samples, sample size Φ30mm ×300mm. The amount of modificator added is 0.3% to 0.6%. The composition of the tested alloy is shown in Table 1.

[0021] Table 1 Chemical composition of test alloys

[0022]

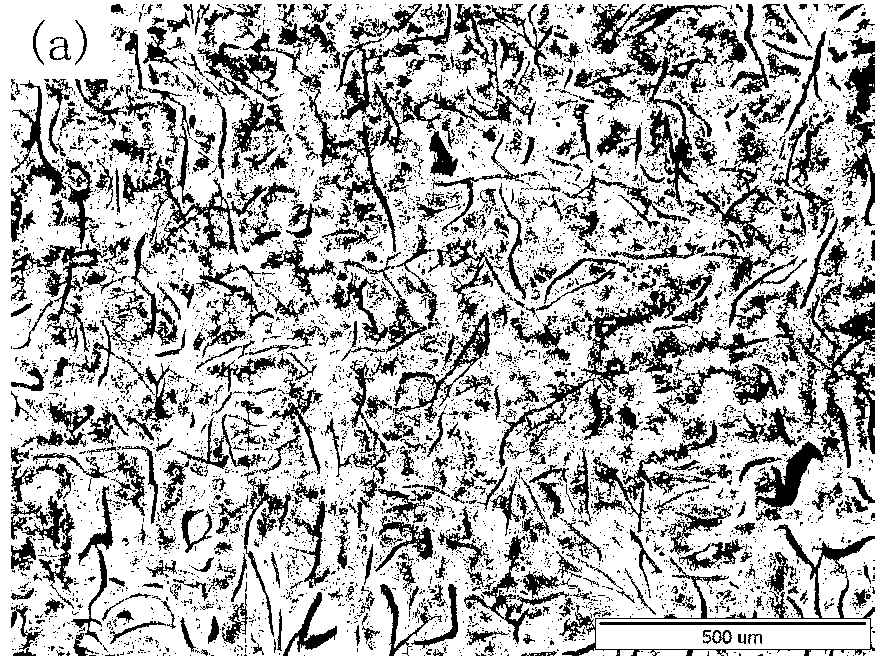

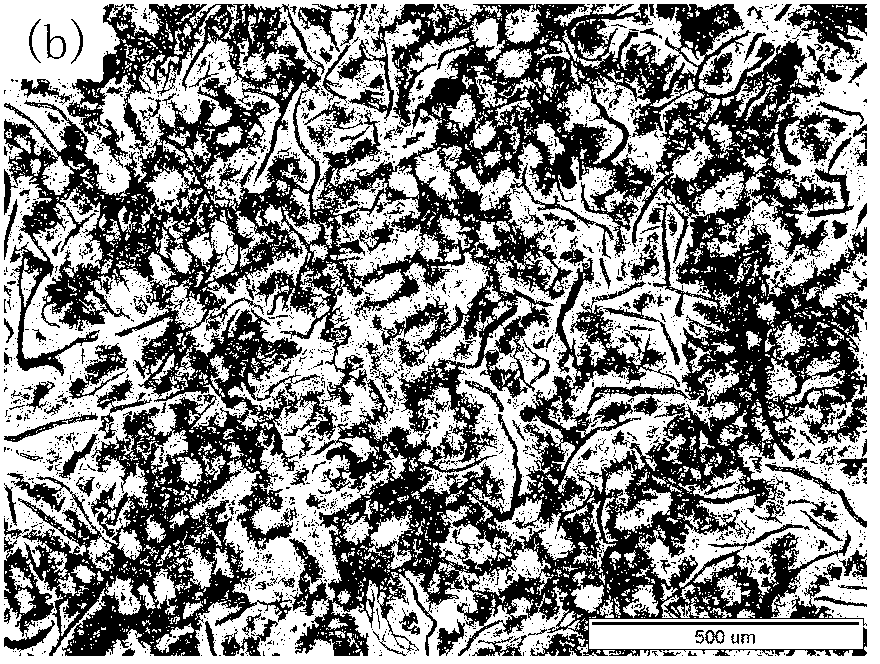

[0023] Figure 1~4 To test the microstructure of gray cast iron after austenitizing annealing. Among them, the black strips are graphite, the bright white ones are primary austenite structures, and the gray-black ones are pearlite structures.

[0024] It can be seen that in the sample A that does not add the modificator of the present invention ( figure 1 ), the graphite is evenly distributed, almost no obvious eutectic group can be seen, or the size of the eutectic group is very large, and a compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com