Integrating method for high-sensitivity temperature-controlled thick film hybrid integrated circuit

A thick-film hybrid and integrated circuit technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems that are not highly sensitive temperature-controlled hybrid integrated circuits, so as to improve long-term reliability, save integration space, The effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The FHTC40 temperature-controlled precision integrated voltage reference source developed by Guizhou Zhenhua Scenery Semiconductor Co., Ltd. is mainly used in the fields of precision measurement and precision control to provide a precise and low-temperature drift voltage reference for the system. The typical working environment temperature is -80°C to 180°C.

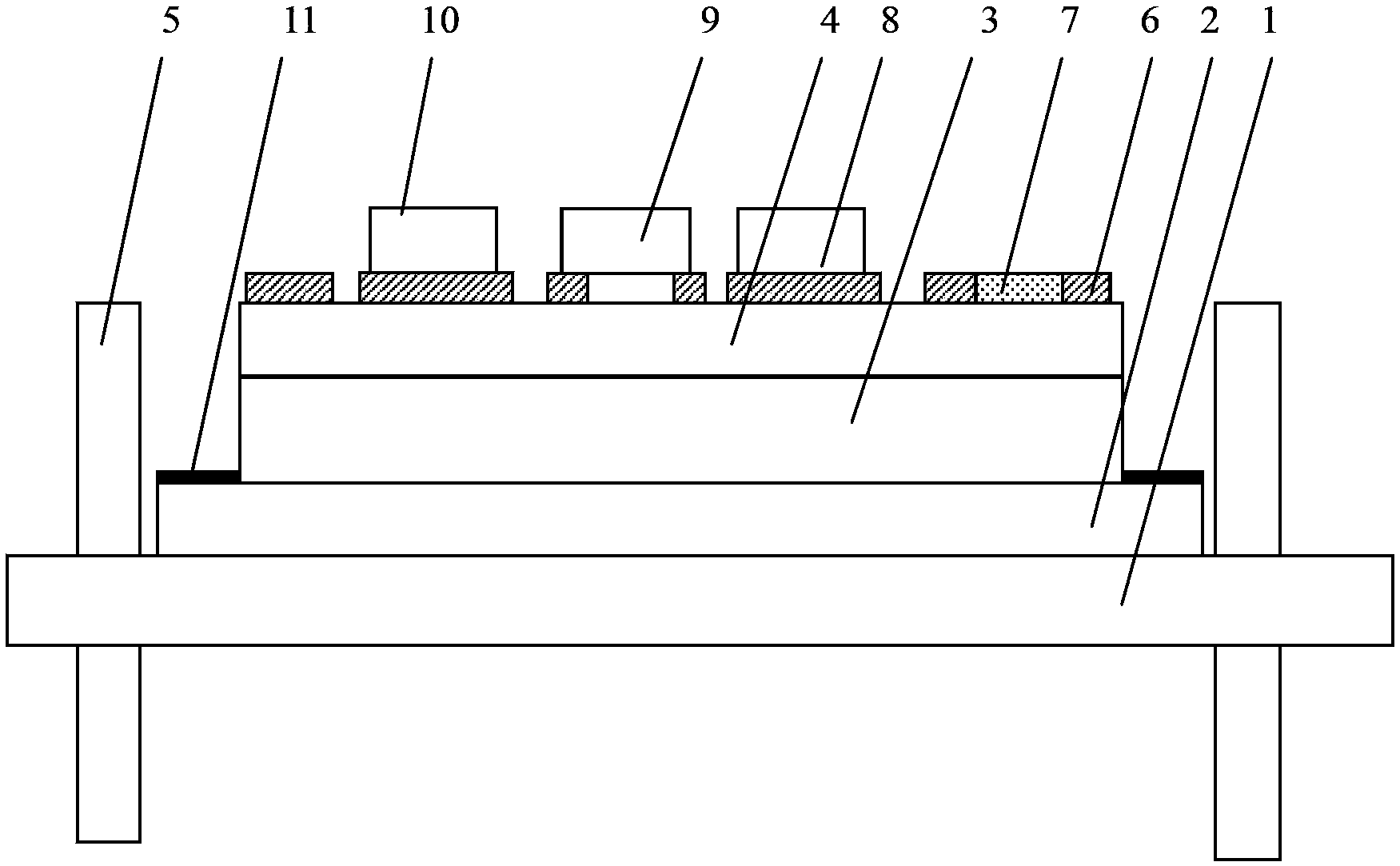

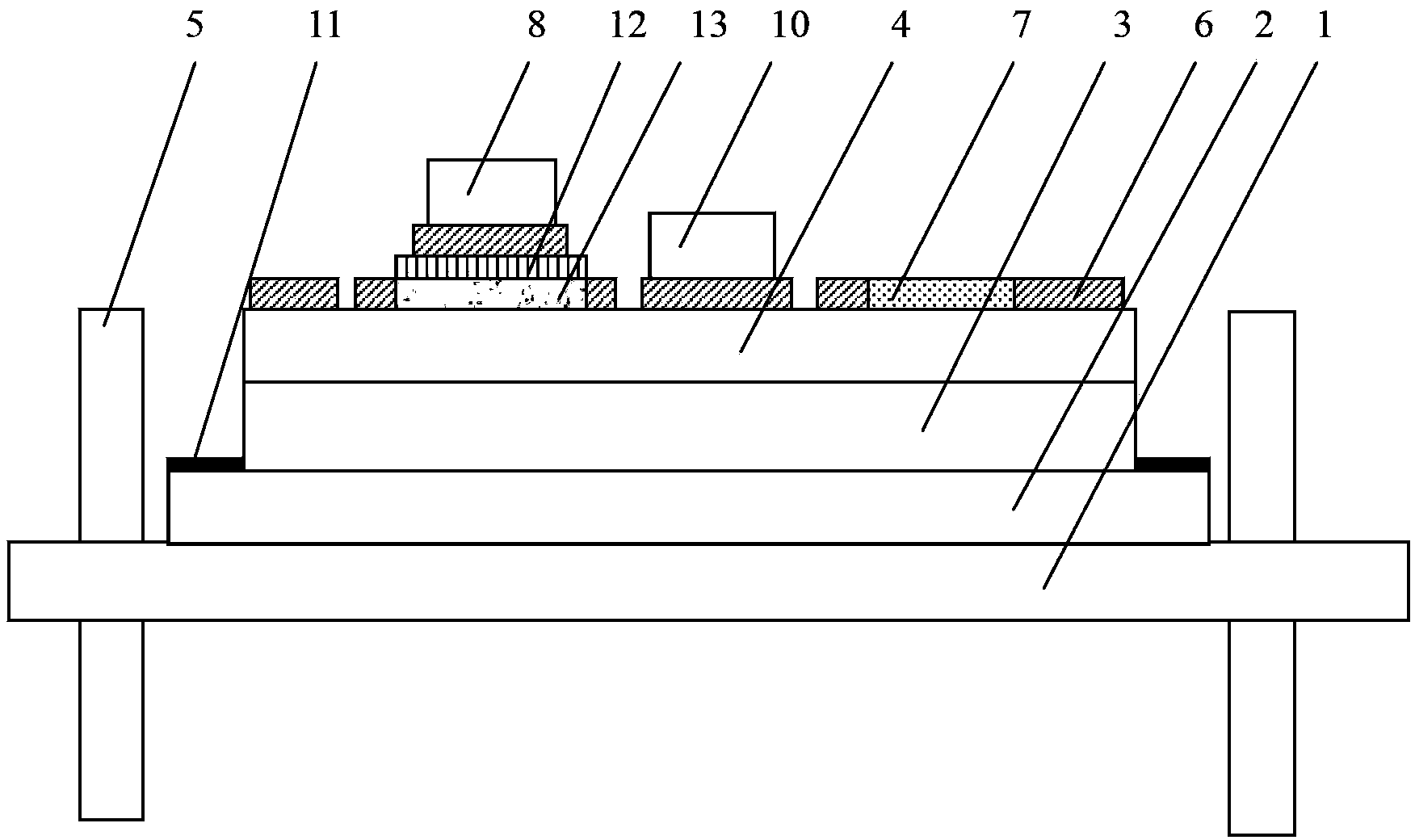

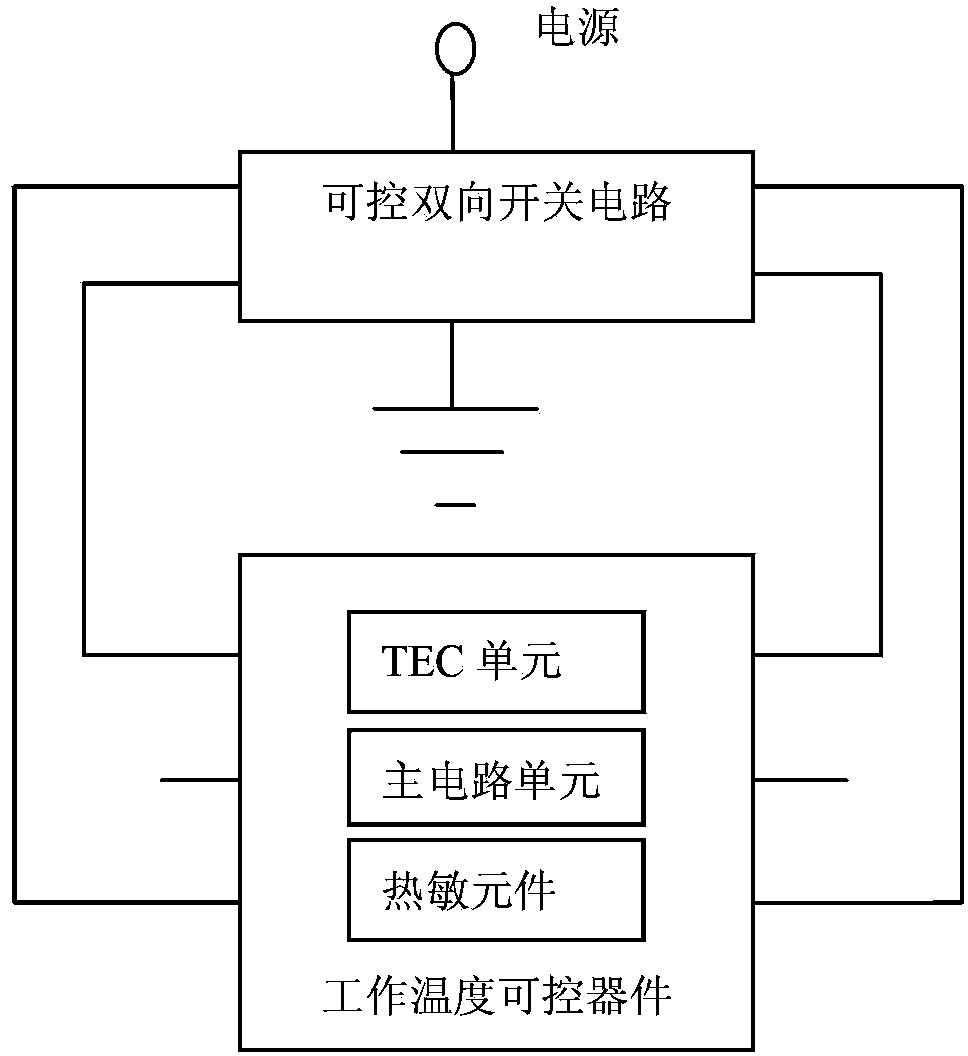

[0025] The core part of the device is a high-precision voltage reference chip, which is the main chip of the device, a self-made thick-film thermistor for temperature control signal acquisition, and a low-power precision operational amplifier chip for temperature control signal processing and amplification. The technology of the present invention-integrated three-dimensional hybrid integration technology of the thick film thermistor and the main chip of the temperature control device is used for production. The specific process is as follows:

[0026] ⑴ Selection of ceramic substrate: In order to facilitate the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com