Preparation of artesunate fat emulsion for injection and application of artesunate fat emulsion in treatment of malaria

A technology of artesunate and water for injection, which is applied in the field of pharmacy, can solve the problems of not being able to be used for injection and not being able to play a role, and achieve the effects of increasing stability, reducing toxic and side effects, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

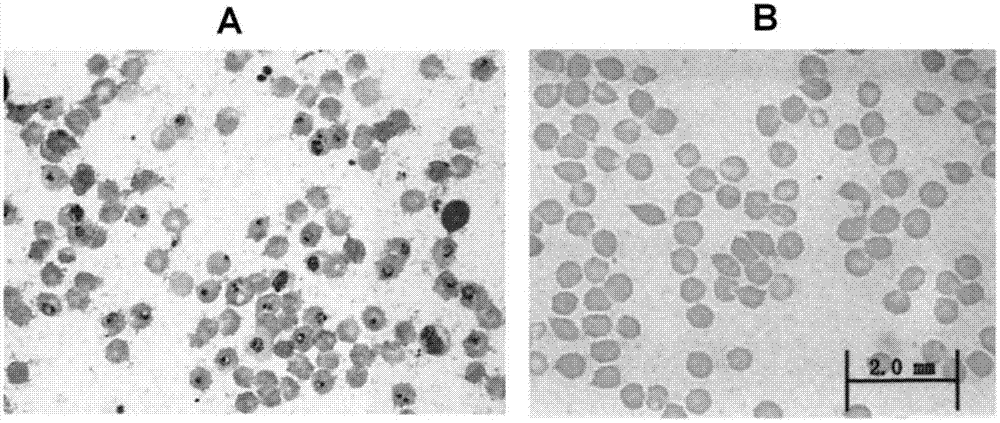

Image

Examples

Embodiment 1

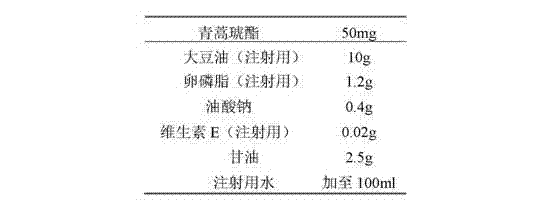

[0029] Prescription:

[0030]

[0031] Put 50mg of artesunate into 1mL of absolute ethanol to fully dissolve into a solution, mix this solution with 10g of soybean oil for injection, evaporate and remove the absolute ethanol, add 1.2g of egg yolk lecithin for injection, 0.02g of egg yolk lecithin under nitrogen protection The antioxidant vitamin E was mixed at 60°C to form an oil phase mixture. Mix 50 mL of water for injection, 0.4 g of sodium oleate and 2.5 g of glycerin at 60° C. to form an aqueous phase mixture. Mix the water phase mixture and the oil phase mixture under the protection of nitrogen, and add water to 100mL. At 60°C, disperse at a high speed of 6500r / min and then mechanically stir for 20min to make colostrum. After adjusting the pH to 7.0, under the condition of a pressure of 105MPa Homogenize 8 times to obtain a homogeneous milky solution; filter the milky solution, seal it with nitrogen gas, sterilize at 115°C for 15 minutes, and store it below 25°C.

Embodiment 2

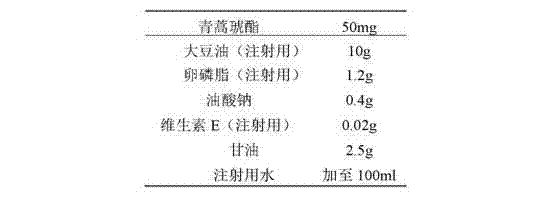

[0033] Prescription:

[0034]

[0035]Put 500mg of artesunate into 5mL of chloroform and fully dissolve into a solution, mix this solution with 10g of olive oil for injection, evaporate and remove the chloroform, add 1.2g of lecithin for injection and 0.02g of antioxidant vitamin E under nitrogen protection , mixed at 70°C to form an oil phase mixture. Mix 70mL of water for injection, 2.5g of xylitol, and 0.2g of F68 at 70°C to form an aqueous phase mixture. Mix the water phase mixture and the oil phase mixture under the protection of nitrogen, add water to 100mL, at 70°C, 7000r / min high-speed dispersion and then mechanically stir for 20min to make colostrum, adjust the pH to 7.5, and carry out under the condition of 90MPa pressure Homogenize 9 times to obtain a homogeneous milky solution; filter the milky solution, seal it with nitrogen gas, sterilize at 120°C for 25 minutes, and store it below 25°C.

[0036] 2. Artesunate fat emulsion injection prepared with different e...

Embodiment 3

[0038] Prescription:

[0039]

[0040] Put 300mg of artesunate into 3mL of acetone to fully dissolve into a solution, mix this solution with 20g of sesame oil for injection, evaporate the acetone, add 2.4g of egg yolk lecithin for injection, 0.02g of antioxidant vitamin E under nitrogen protection , mixed at 70°C to form an oil phase mixture. Mix 150mL of water for injection, 5g of glycerin, and 0.02g of oleic acid at 70°C to form an aqueous phase mixture. Mix the water phase mixture and the oil phase mixture under the protection of nitrogen, add water to 200mL, at 70°C, 7500r / min high-speed dispersion, then mechanically stir for 20min to make colostrum, adjust the pH to 8.0, and carry out under the condition of 95MPa pressure Homogenize 6 times to obtain a uniform milky solution; filter the above milky solution, seal it with nitrogen gas, sterilize at 125°C for 10 minutes, and store it below 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com