Device and method for electro-dynamic migration recovery and cyanogen-containing waste gas purification

An exhaust gas treatment device and electric power technology, applied in chemical instruments and methods, separation methods, preparation/purification/separation of hydrogen cyanide, etc., can solve problems such as secondary pollution and large consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

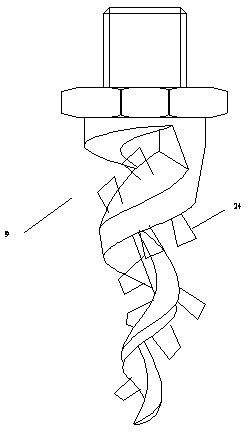

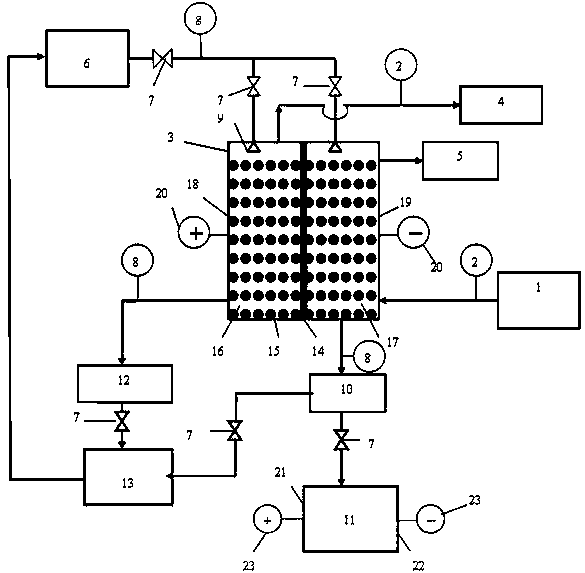

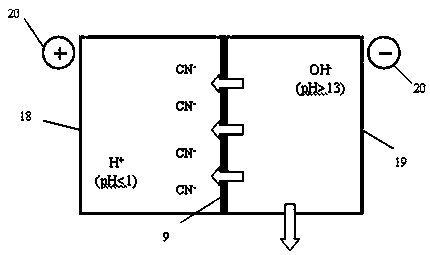

[0025] use as figure 1 A device for recovering and purifying cyanide-containing waste gas by electrodynamic migration is shown to recover HCN in carbon fiber cyanide-containing waste gas. The concentration of HCN in the exhaust gas is 30mg / m 3 , the flow rate is 100m 3 / h, the residence time is 10min, after passing through the device of electrodynamic migration recovery and purification of cyanide-containing waste gas, HCN gas with a purity of 98%-99.5% can be obtained in the HCN recovery storage tank, and the gas discharged after being treated by the cathode electro-Fenton device The content of HCN in the gas is less than 0.05mg / Nm 3 , lower than the maximum allowable concentration of HCN national standard is 0.3mg / Nm 3 . Among them, the size of the electric exhaust gas treatment device is 3m*4m*10m, the anode is a titanium ruthenium-plated mesh electrode, the cathode is a stainless steel mesh electrode, and the inert filler is an active ceramic ball.

Embodiment 2

[0027] Two sets of electric waste gas treatment devices are used in series to recover HCN in calcium carbide furnace gas. The operation steps and HCN recovery principle are the same as those in Example 1. The concentration of HCN in the exhaust gas is 2.45g / m 3 , the flow rate is 1000m 3 / h, the furnace gas enters the two-stage electric waste gas treatment device in two ways, and the residence time is 20 minutes. After passing through the device for electric power migration recovery and purification of cyanide-containing waste gas, the purity of 97%-98.5% can be obtained in the HCN recovery storage tank. HCN gas, the content of HCN in the discharged gas after being treated by the cathode electro-Fenton device is less than 0.25mg / Nm 3 , lower than the maximum allowable concentration of HCN national standard is 0.3mg / Nm 3 . Among them, the size of each stage of electric exhaust gas treatment device is 5m*4m*10m, the anode is titanium ruthenium plated mesh electrode, the c...

Embodiment 3

[0029] In Example 3, two sets of electric waste gas treatment devices are used to recover HCN in calcium carbide furnace gas in series. The operation steps and HCN recovery principle are as follows: Figure 4 shown. The concentration of HCN in the exhaust gas is 2.45g / m 3 , the furnace gas enters the two-stage electric waste gas treatment device in two ways, and the residence time is 20 minutes. After passing through the device for electric power migration recovery and purification of cyanide-containing waste gas, the gas contains 24.5 mg / m after the HCN absorption and recovery of HCN in the first stage 3 , and then after the second stage of absorption, the content of HCN in the discharged gas is lower than 0.24mg / Nm 3 , reaching a maximum allowable concentration lower than the HCN national standard of 0.3mg / Nm 3 requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com