Gas purification device

A gas purification device and gas treatment technology, applied in the direction of solid separation, chemical instruments and methods, external electrostatic separators, etc., can solve the problems of low efficiency and poor purification effect, and achieve good effect, high purification efficiency and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

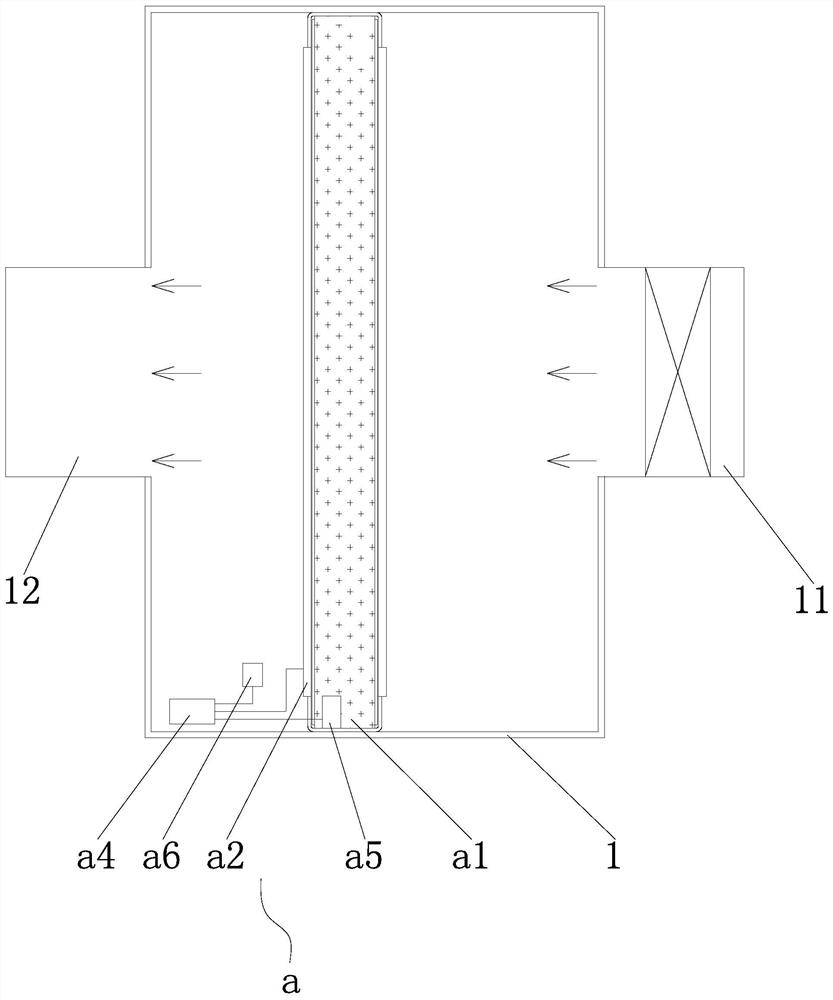

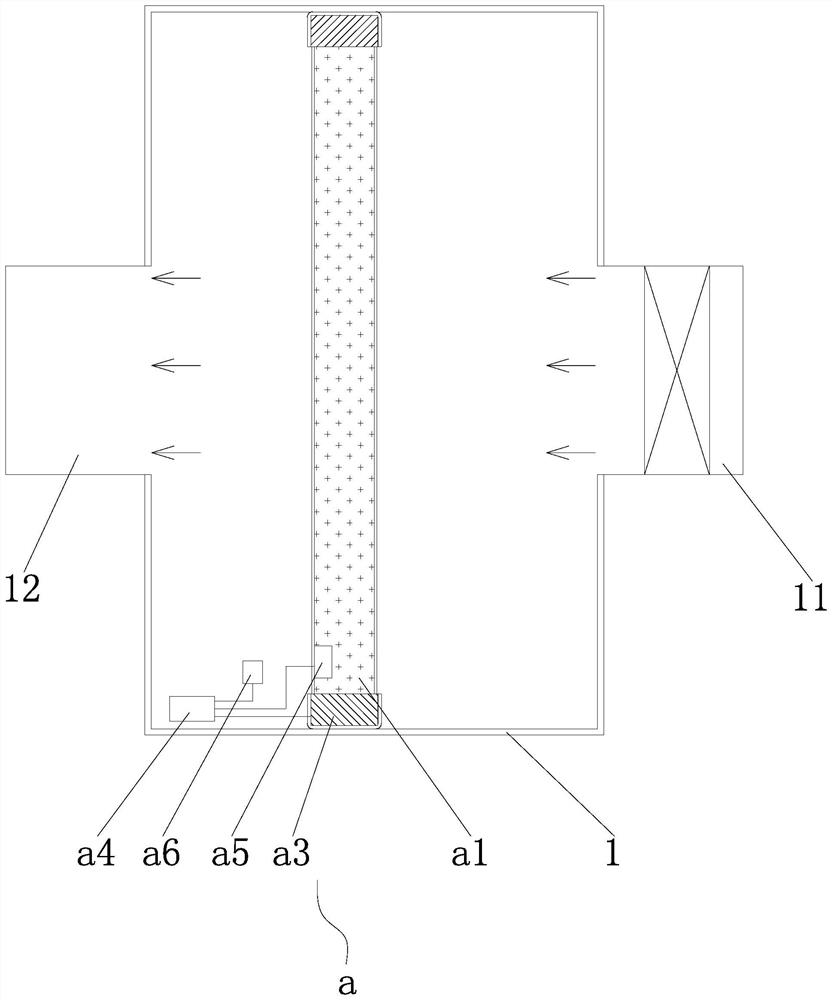

[0067] like figure 1 and figure 2 As shown, a gas purification device mainly includes a casing 1 and an activated carbon purification mechanism a set in the casing 1, the casing 1 is provided with an air inlet 11 and an air outlet 12, the activated carbon purification mechanism a It includes an activated carbon layer a1 and a temperature control assembly for controlling the temperature of the activated carbon layer a1. When the gas to be treated flowing from the shell 1 passes through the activated carbon layer a1 for adsorption and purification treatment, the temperature control assembly controls the activated carbon layer. a1 is at the first temperature, and the first temperature is higher than the dew point temperature of the gas to be treated. A fan can be installed in the casing 1 to make the gas inhaled from the air inlet 11, and then flow through the casing and pass through the activated carbon layer a1 , and finally discharged from the air outlet 12 , or an external ...

Embodiment 2

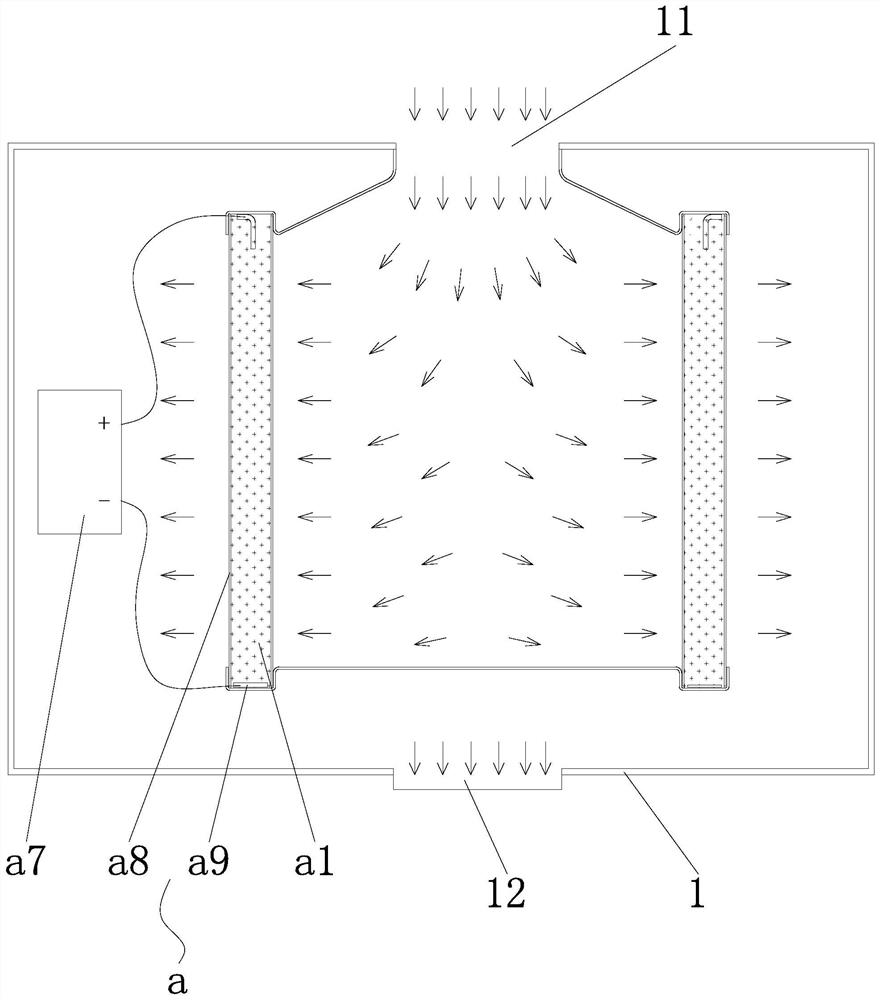

[0076] like image 3As shown, the difference from the first embodiment is that the temperature control component adopts a temperature control power supply a7, and the temperature control power supply a7 is electrically connected to the activated carbon layer a1 to energize the activated carbon layer a1, and the resistance of the activated carbon layer a1 is very large, The conductivity is relatively low, and the activated carbon layer a1 can heat itself when a low-voltage current is applied to the activated carbon layer a1. Different from using an additional heat source to conduct heat conduction to the activated carbon layer, this embodiment adopts the method of electrification to make the activated carbon layer a1 self-heating , the implementation is more convenient and simple, the structure is more compact, the energy utilization rate is high, and the power consumption is low.

[0077] In this embodiment, the activated carbon layer a1 has a cylindrical structure, the two ax...

Embodiment 3

[0080] like Figure 4 As shown, the shell 1 is provided with an activated carbon purification mechanism a and an electrostatic purification mechanism b, and the electrostatic purification mechanism b and the activated carbon purification mechanism a are sequentially arranged along the direction of the airflow in the shell. The treatment gas is ionized and the pollutants are charged. Under the action of the electric field force, it moves to the electrode of the electrostatic field and adheres to the electrostatic electrode to be deposited to realize the separation of the pollutant and the gas. First, the electrostatic unit is used to effectively remove the pollutants with large particle size. , can reduce the purification treatment pressure of the subsequent activated carbon layer, reduce the occurrence of clogging of the activated carbon layer, ensure the smoothness of air flow, enable the entire purification process to be carried out stably, and ensure the purification effect....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com