Treatment method of coking waste water

A technology for coking wastewater and treatment method, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor biodegradability of wastewater, unsatisfactory treatment effect, and complex coking wastewater composition. Changes and other issues, to achieve the effect of protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

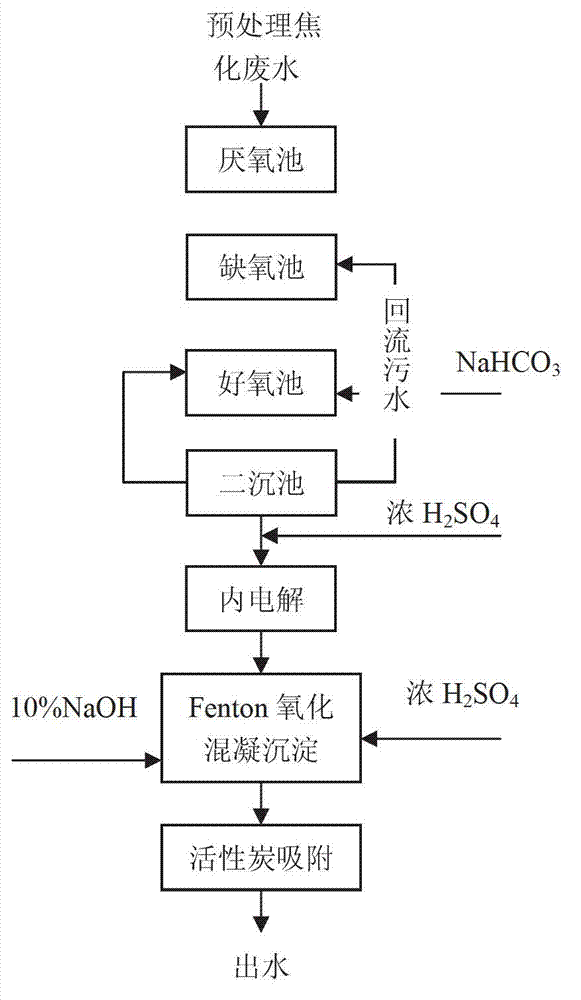

[0022] A: Biochemical treatment of coking wastewater:

[0023] Use A 2The O process, that is, the anaerobic-anoxic-aerobic biological denitrification process, adopts the activated sludge method, and the activated sludge is inoculated with the sludge from the secondary sedimentation tank of the coking wastewater treatment plant. The pretreated wastewater is first pumped into the anaerobic tank, and the sludge concentration in the anaerobic tank is controlled to be 7000mg / L, and the residence time is controlled at 10h; L, the residence time is controlled at 15h; the effluent from the anoxic tank flows into the aerobic tank, and the sludge concentration in the aerobic tank is controlled to 4000mg / L, and NaHCO is added 3 The solution controls the pH of the wastewater to be 7, the residence time is controlled at 15h, the effluent flows into the secondary settling tank, the sludge reflux ratio of the secondary settling tank is controlled to 1:1, the nitrification liquid reflux rati...

Embodiment 2

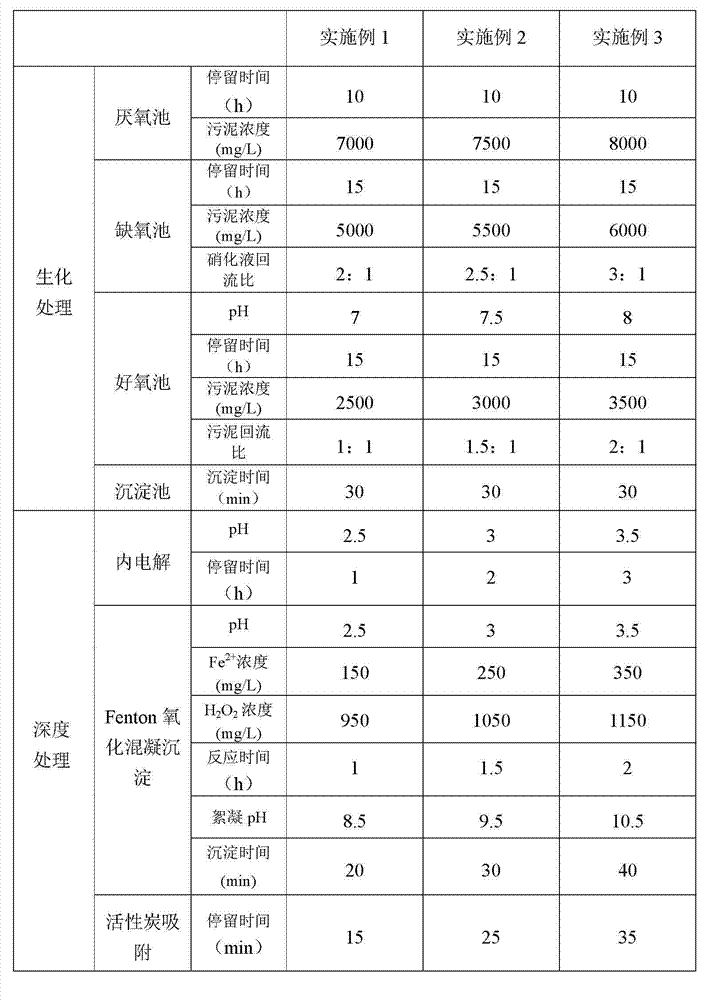

[0027] The experimental parameters in embodiment 2 and embodiment 3 are selected with reference to table 1.

[0028] Table 1 Experimental parameters of each embodiment

[0029]

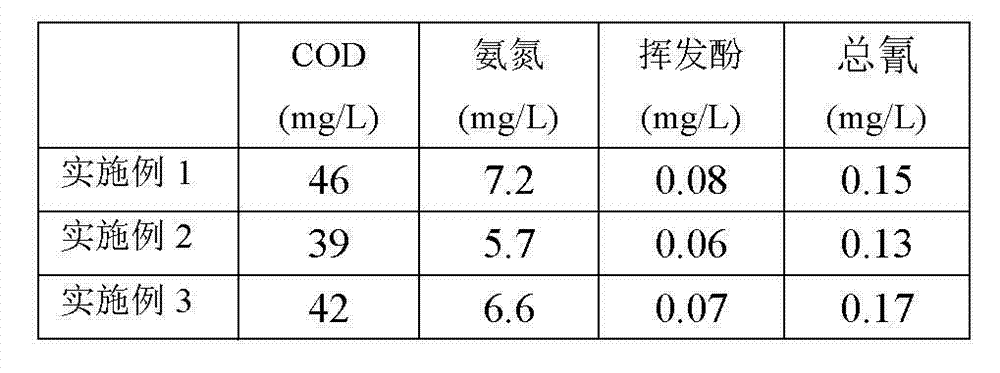

[0030] The main water quality indicators of coking wastewater influent are: COD: 3460mg / L, ammonia nitrogen: 140mg / L, volatile phenols: 1050mg / L, total cyanide: 30mg / L, pH: 8.5, each embodiment has undergone the above biochemical treatment + advanced treatment Finally, the main indicators of the effluent are shown in Table 2.

[0031] Table 2 The removal effect of each embodiment on pollutants

[0032]

[0033] From the results in Table 2, it can be seen that the coking wastewater after the above biochemical treatment + advanced treatment, COD≤50mg / L, ammonia nitrogen≤8mg / L, volatile phenol≤0.3 mg / L, total cyanide≤0.2 mg / L, the process effluent water quality Stable and meet the requirements of comprehensive sewage discharge standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com