Application of catalyst component in olefin polymerization

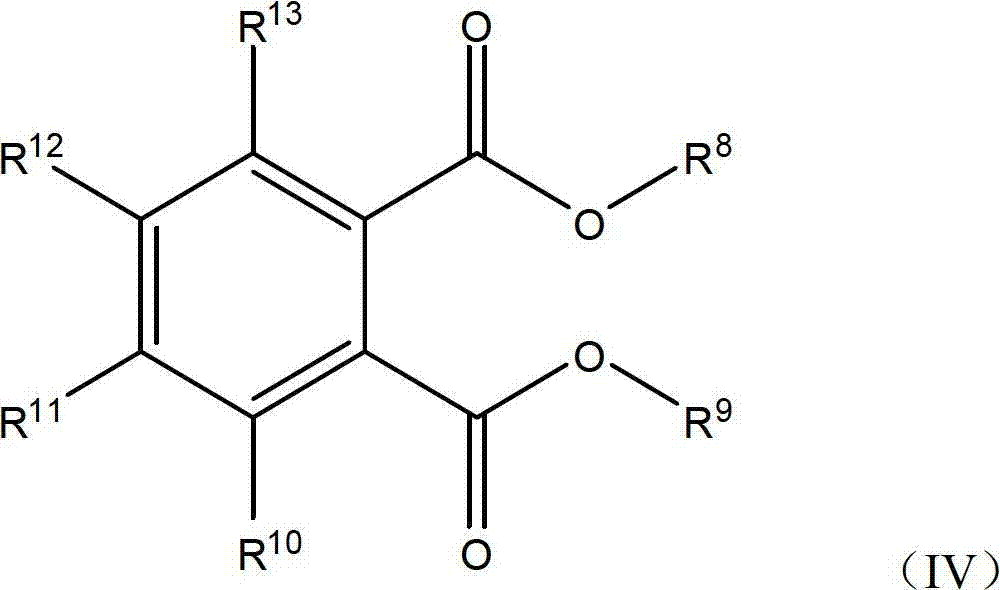

A technology of olefin polymerization and catalyst, which is applied in the field of catalysis in olefin polymerization in a high temperature state, and can solve problems such as high temperature polymerization activity and polymer isotacticity need to be further improved, and polymerization process is complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

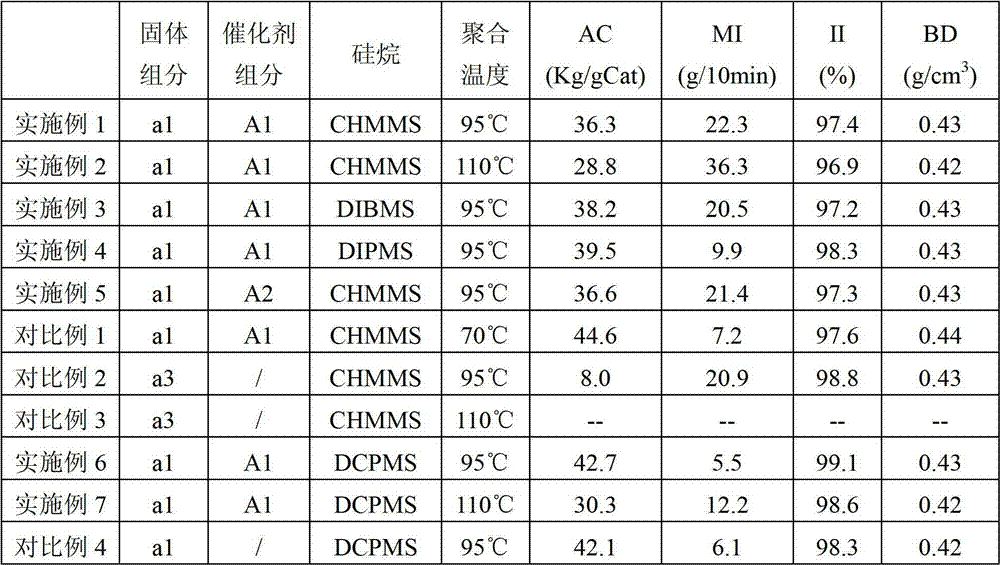

Embodiment 1

[0069] Preparation of solid component a1:

[0070] Take 10 grams of the alkoxymagnesium carrier prepared in the preliminary example, 50 mL of toluene, and 2.5 mL of di-n-butyl phthalate to prepare a suspension; 40mL and 60mL of titanium tetrachloride, then add the prepared suspension into the kettle, raise the temperature to 80°C, keep the temperature for 1 hour, then continue to raise the temperature to 115°C, and press filter the liquid (mother liquor) after keeping the temperature for 2 hours. Then add 120mL of toluene and 30mL of titanium tetrachloride to the mixed solution and raise the temperature to 110°C and stir for 1 hour (titanium treatment). This is done 3 times, and the liquid is filtered off. The obtained solid is washed 4 times with 120mL of n-hexane at 50°C. Remove the liquid and dry to obtain the solid component a1 of the present invention. The titanium content in the obtained solid component a1 was 2.4 wt%.

[0071] Preparation of olefin polymerization cata...

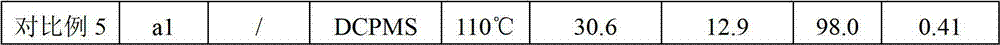

Embodiment 2

[0079] The preparation method of solid component a1 and olefin polymerization catalyst component A1 is the same as in Example 1; according to the polymerization method of Example 1, only the polymerization temperature is changed from 95°C to 110°C for polymerization.

Embodiment 3

[0081] The preparation method of solid component a1 and olefin polymerization catalyst component A1 is the same as in Example 1; according to the preparation method of polyolefin in Example 1, only the external electron donor cyclohexylmethyldimethoxysilane (CHMMS) is replaced by Diisobutyldimethoxysilane (DIBMS) for polymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com