Terahertz wave polarization beam splitter with trapezoidal structures loaded on borders

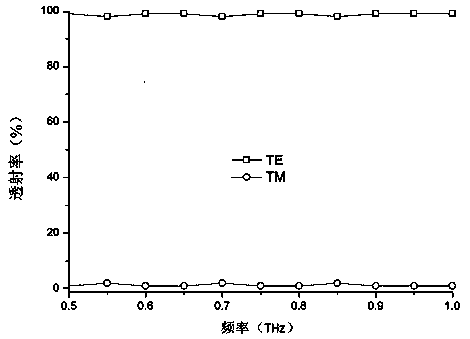

A polarization beam splitter and trapezoidal structure technology, applied in the coupling of optical waveguides, etc., can solve the problems of difficult manufacturing process, low beam splitting rate, complex structure, etc., and achieve the effect of simple structure, high beam splitting rate and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

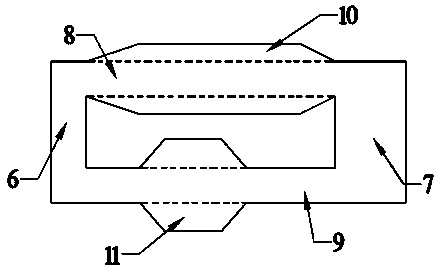

[0016] Terahertz wave polarizing beam splitter with trapezoidal structure loaded on the frame:

[0017] The length of the signal input end is 500 μm, the width is 200 μm, and the thickness is 150 μm. Both the first signal output end and the second signal output end have a length of 500 μm, a width of 200 μm, and a thickness of 150 μm. The far-infrared quartz glass substrate has a length of 2000 μm, a width of 1600 μm, and a thickness of 500 μm. The thickness of the polarizing beam splitter is 150 μm. The narrow rectangular polarized silicon waveguide on the left has a width of 300 μm and a length of 500 μm; the wide rectangular polarized silicon waveguide on the right has a width of 400 μm and a length of 500 μm. The upper rectangular polarized silicon waveguide has a width of 300 μm and a length of 800 μm; the lower rectangular polarized silicon waveguide has a width of 300 μm and a length of 800 μm. The length of the upper base of the long trapezoidal polarization silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com