Online monitoring and maintaining system for plastic extrusion units

A technology for plastic extruders and extrusion units, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of data recording and low production efficiency, improve quality and production efficiency, and enhance market competition The effect of shortening force and failure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

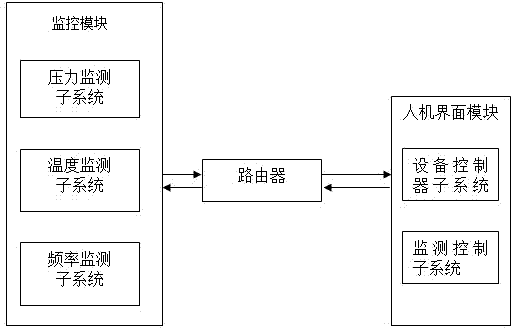

[0016] Such as figure 1 As shown, the online monitoring and maintenance system of the plastic extrusion unit of the present invention includes a monitoring module, a router and a man-machine interface module; the monitoring module is connected to the man-machine interface module through a router; the monitoring module measures the online process of the plastic extruder parameters, and transmit the data to the man-machine interface module through the router; the man-machine interface module decapsulates the data transmitted by the router, displays the decapsulated data, and transmits the changed process parameters to the monitoring module through the router .

[0017] The monitoring module includes a temperature monitoring subsystem, a pressure monitoring subsystem and a frequency monitoring subsystem; the temperature monitoring subsy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com