Method for preparing porous hybridization NiO/Co3O4 electrode material of super capacitor

A technology for supercapacitors and electrode materials, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of limiting large-scale practical applications of energy storage, low output of synthetic products, low repetition rate, etc., and achieve good supercapacitor performance with simple methods , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

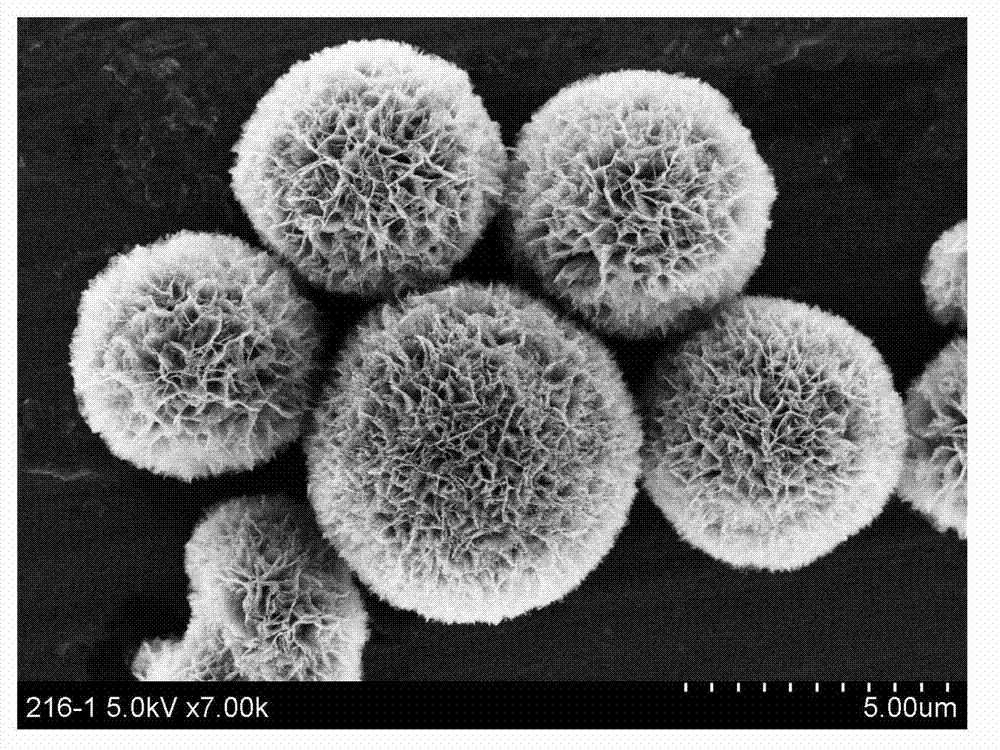

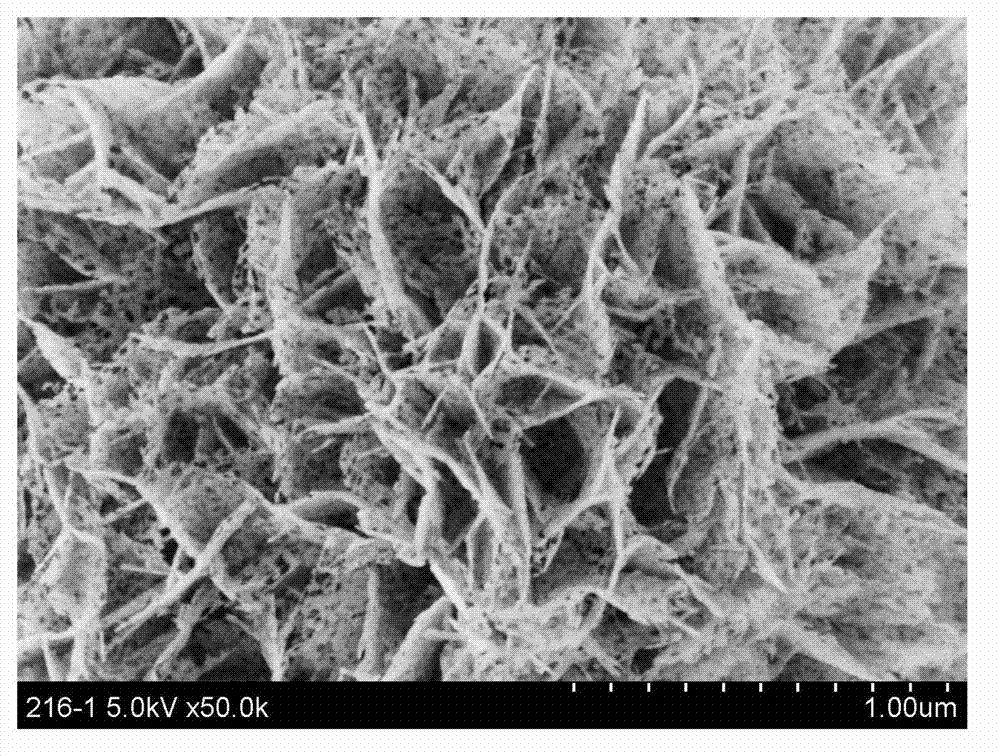

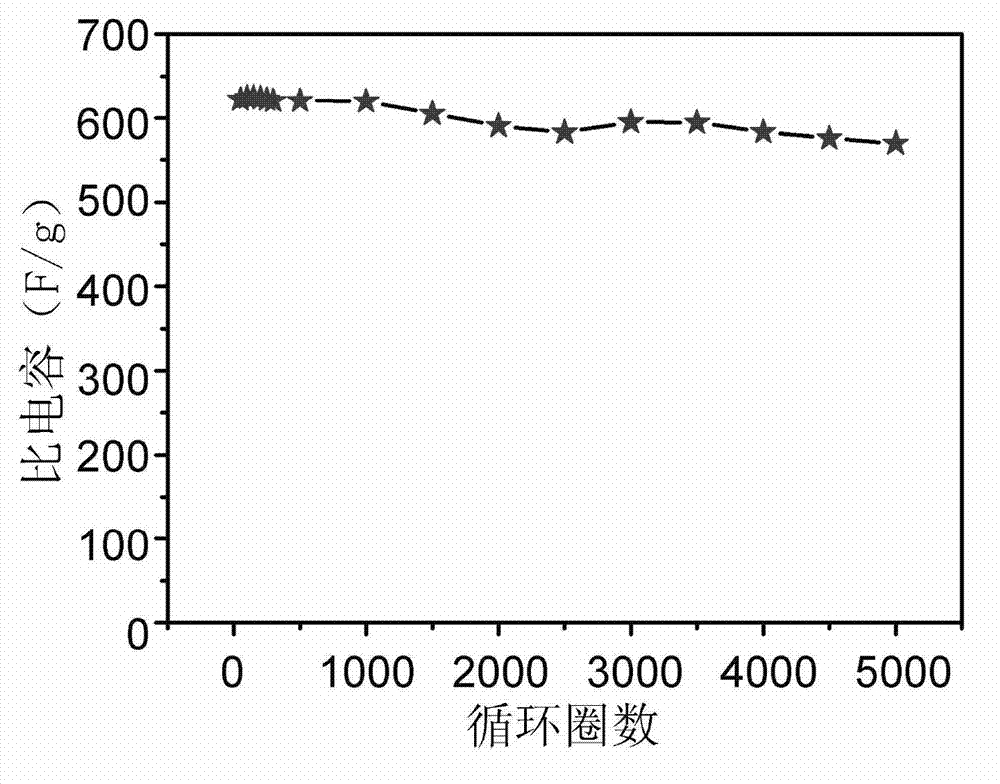

[0029] (1) Weigh the raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 2.72mmol, cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 (0) 0.68mmol and 0.5g of polyvinylpyrrolidone (PVP) were dissolved in methanol and water, and stirred to prepare a mixed solution; wherein, the volumes of methanol and water were 43ml and 5ml respectively;

[0030] (2) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle to maintain a filling degree of 80%, put the hydrothermal reaction kettle into a blast drying oven, and react under hydrothermal conditions of 180°C for 6 hours, Afterwards, the reaction kettle was cooled to room temperature.

[0031] (3) The product obtained by centrifugation was washed with deionized water and ethanol solvent respectively, and dried; the dried sample was placed in a muffle furnace and calcined at 450°C for 40 minutes; the final black sample obtained was a supercapacitor electrode material.

Embodiment 2

[0033] (1) Weigh the raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 2.04mmol, cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) 1.36mmol and 0.5g of polyvinylpyrrolidone (PVP) were dissolved in methanol and water, and stirred to prepare a mixed solution; wherein, the volumes of methanol and water were 43ml and 5ml respectively;

[0034] (2) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle to maintain a filling degree of 80%, put the hydrothermal reaction kettle into a blast drying oven, and react under hydrothermal conditions of 180°C for 6 hours, Afterwards, the reaction kettle was cooled to room temperature.

[0035](3) The product obtained by centrifugation was washed with deionized water and ethanol solvent respectively, and dried; the dried sample was placed in a muffle furnace and calcined at 450°C for 40 minutes; the final black sample obtained was a supercapacitor electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com