Treatment method for biological decayed off-gas

A treatment method and technology for polluted gas, applied in the direction of combustion methods, separation methods, chemical instruments and methods, etc., can solve problems such as cumbersome steps, complicated processes, and unsatisfactory effects, and achieve simple equipment, elimination of environmental pollution, and low treatment costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention is described in further detail.

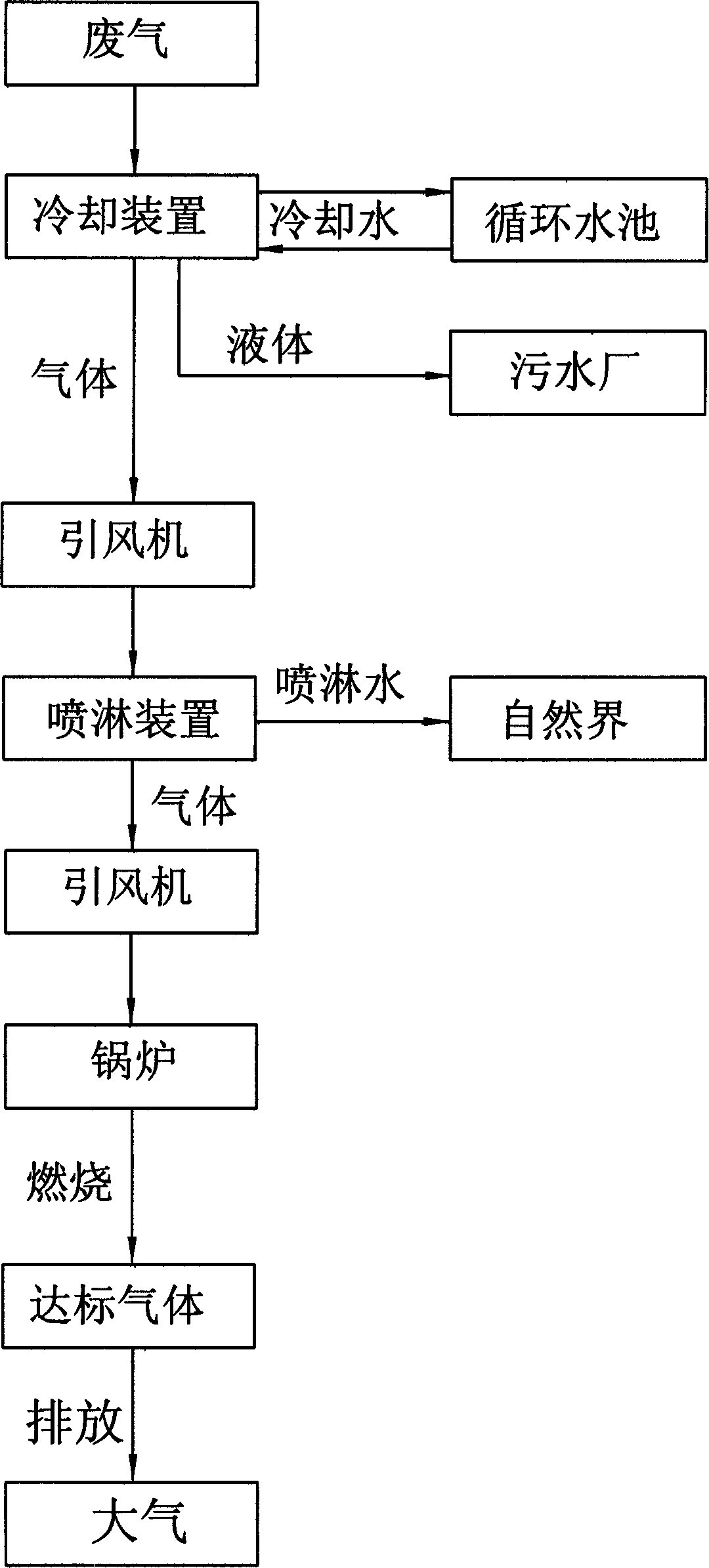

[0022] Figure 1 to Figure 6 Shown, the processing method of this biological decay pollution gas, comprises the following steps successively:

[0023] 1. Cooling: The biological decay gas is cooled in the cooler through the pipeline, so that part of the biological decay gas is cooled into liquid, and the cooled liquid is connected to the sewage pipe of the sewage plant through the pipeline; and after cooling Finally, the unliquefied sewage gas flows to the spraying device through the pipeline under the action of the induced draft fan;

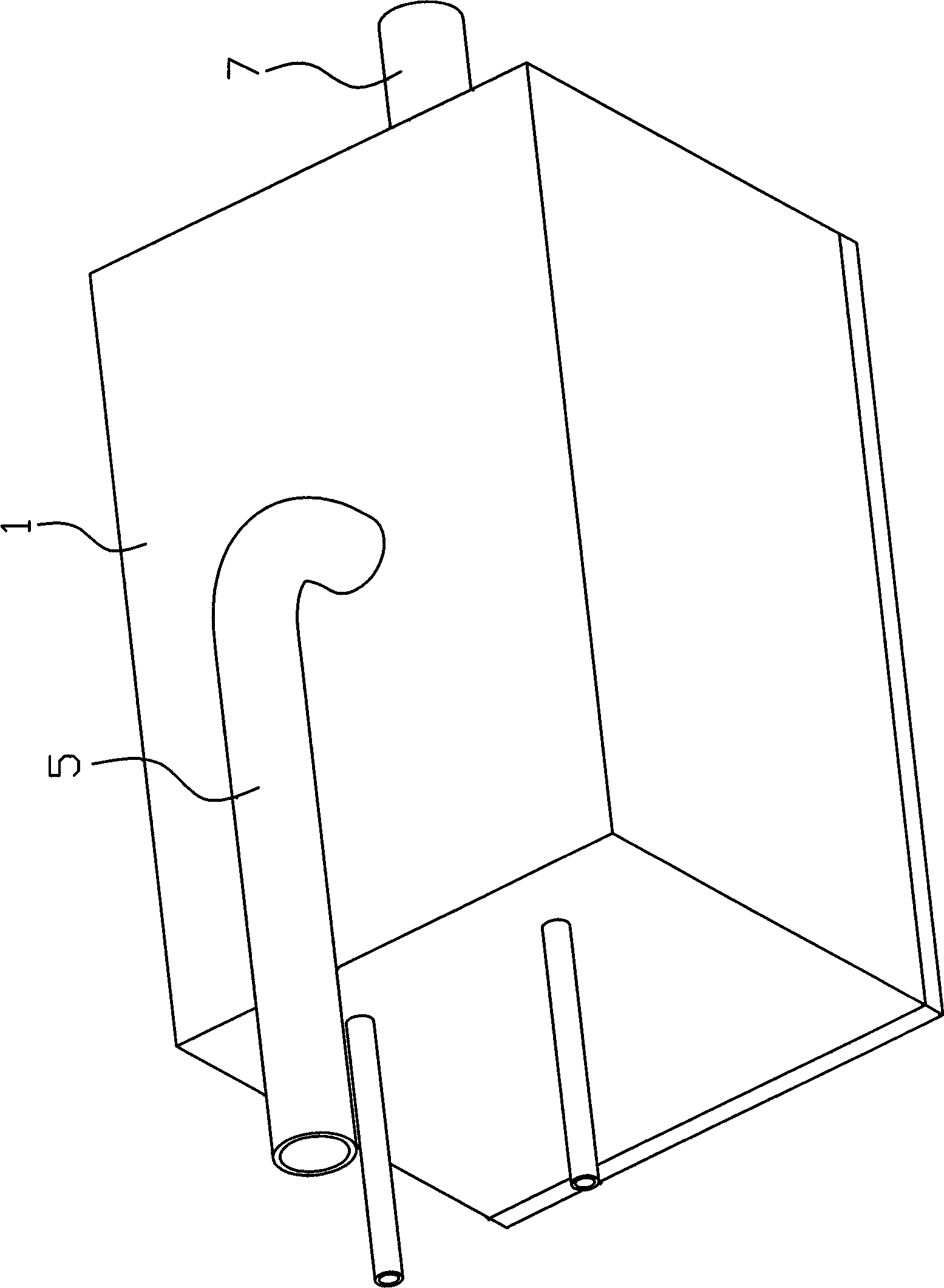

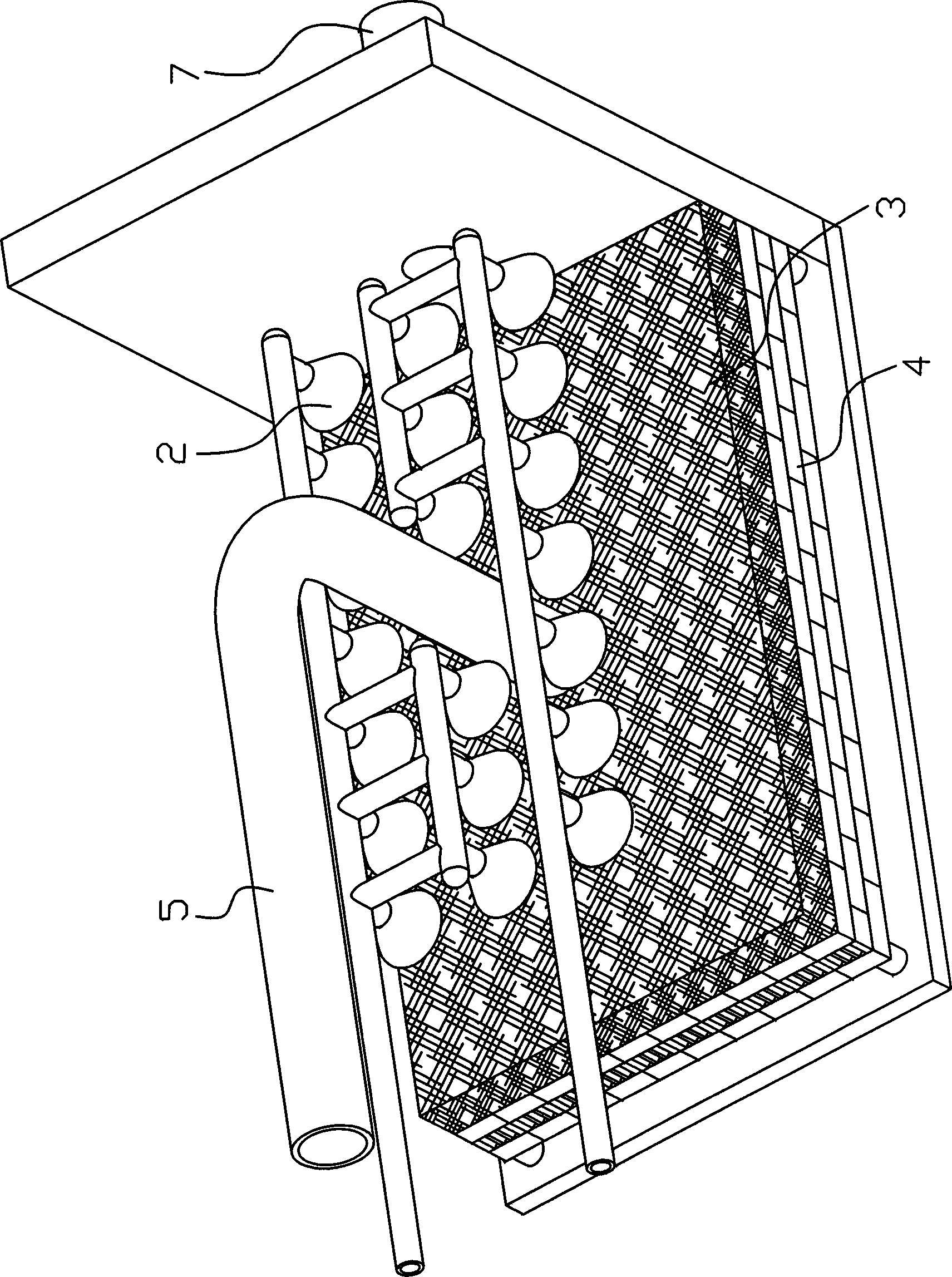

[0024] 2. Adsorption and filtration: The dirty gas entering the spraying device first enters the gas distribution chamber at the bottom of the spraying device, and the gas entering the distribution chamber is dispersed and then flows upwards and then passes through the adsorption layer and the filter layer to rise to the spraying device Spray a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com