Blank preparation process for shafts

A preparation process and shaft blank technology, applied in the field of shaft blank processing, can solve the problems of high management cost, difficulty in unified coordination and control, scattered management and quality control, etc., to achieve less material burning loss, reduction of production and logistics links, management and Easy effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in combination with specific embodiments.

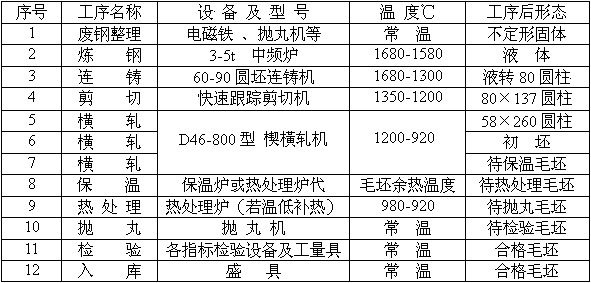

[0019] The blank preparation process of the shaft of the present invention, its preparation steps are:

[0020] 1) Firstly, the scrap steel is smelted to produce molten steel that meets the requirements of the shaft billet; during smelting, the element composition and content are increased or decreased according to the composition requirements of the shaft billet.

[0021] 2) When the obtained molten steel is at 1680-1580°C, pour it into the continuous casting machine and draw it into a round billet with a certain diameter, and then cut the drawn round billet to the required length at the temperature of 1350-1200°C; When shearing, it moves synchronously with the billet, so as not to affect the forming process of the billet, and returns to the original position after shearing.

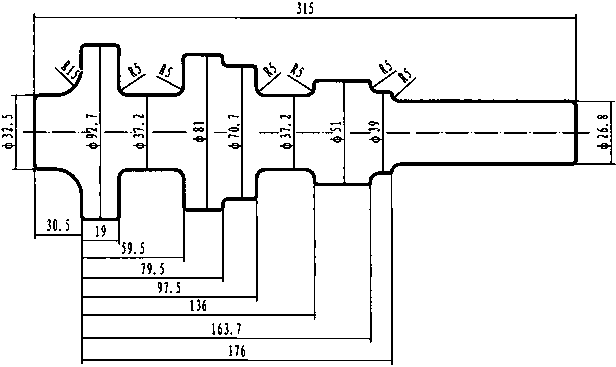

[0022] 3) The sheared billet is cross-rolled at a temperature of 1200-900°C into a semi-fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com