Treatment method and device for high-concentration organic wastewater

A technology of organic wastewater and treatment methods, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, separation methods, etc., can solve the problems of high aerobic load, low anaerobic efficiency, and high cost, and achieve reduction Organic content, inhibition of sludge bulking, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

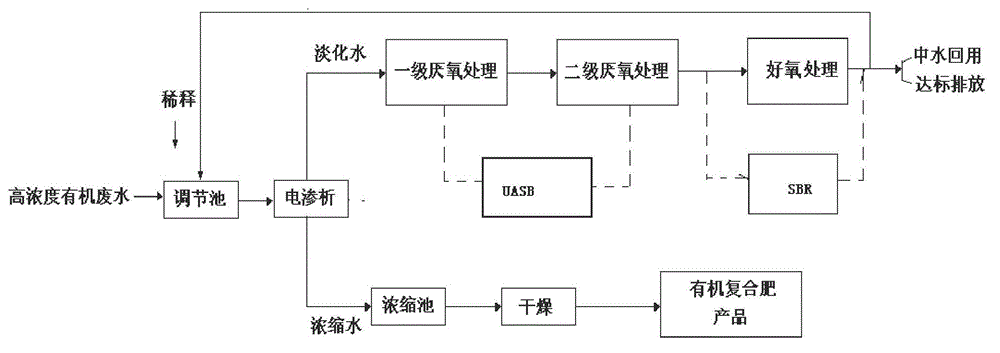

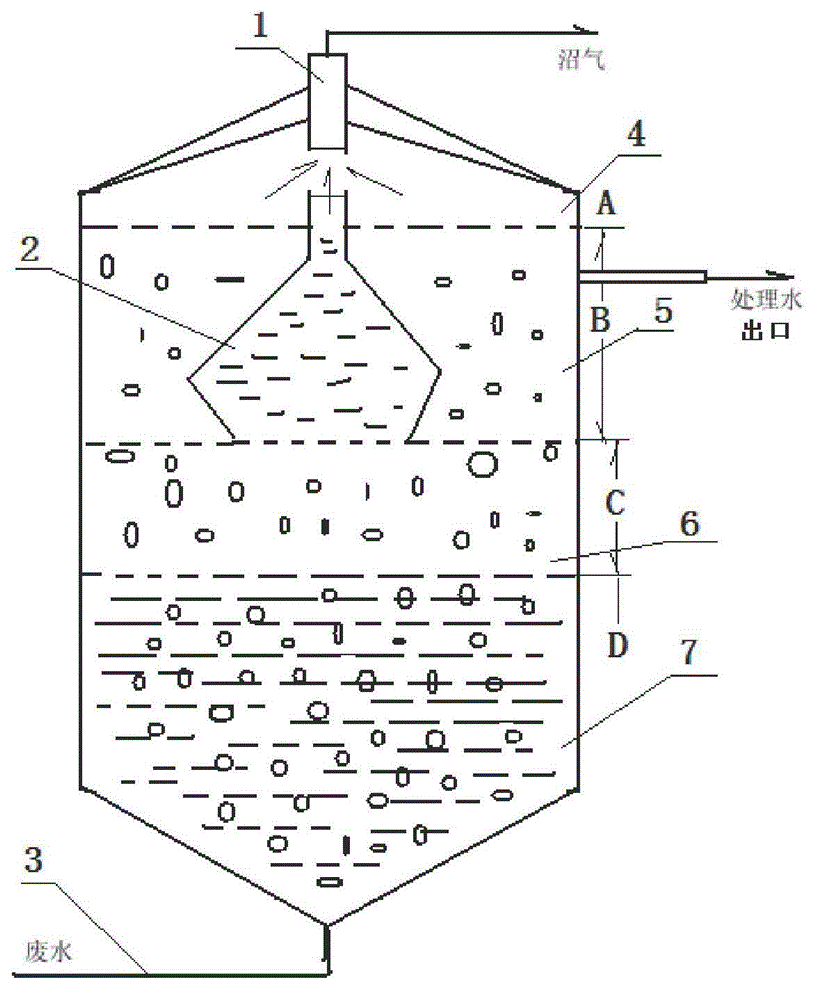

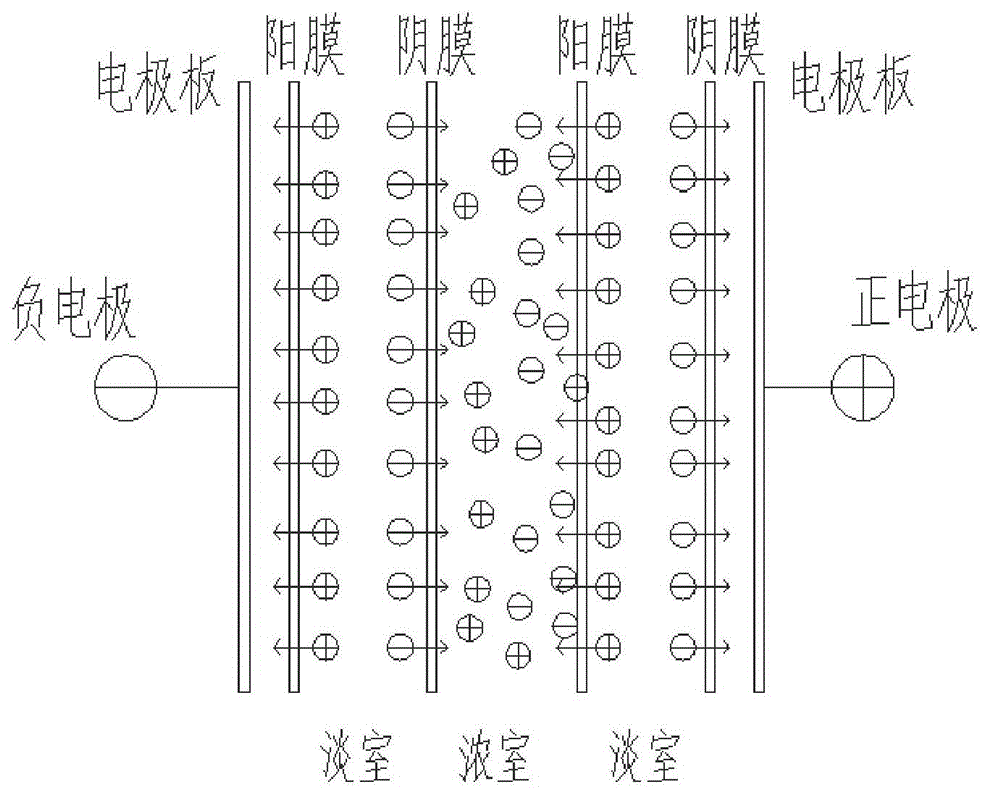

[0073] Example 1: The molasses yeast wastewater of a sugar company in Guangxi has a COD of about 5500 mg / L, a total salt content of about 6000 mg / L, and a potassium ion content of about 540 mg / L. The wastewater has poor biochemical properties. After processing on a small scale in the laboratory, since there is no obvious peak on the desalination trend graph in the single-factor experiment stage, the orthogonal experiment design method is used to design the experiment, and the best combination of desalination parameters obtained is: flow rate 30L / h, voltage 60V , the pH value is 7. Under this optimal combination, the desalination rate reached 89.6%, and the BOD5 / COD value of molasses yeast wastewater after electrodialysis treatment rose from 0.293 of raw water to 0.477, and the biochemical properties of wastewater were significantly improved. The treated desalinated liquid is reused after anaerobic treatment and aerobic treatment, and the concentrated liquid is re-concentrate...

Embodiment 2

[0074] Example 2, a paper mill in Guangxi produced washing wastewater containing a large amount of pollutants such as inorganic salt ions and cellulose during the pulp washing stage. In the past, although the electrodialysis treatment system was used, because it only considered the influence of inorganic salt ions in the wastewater and did not consider other conditions, it was difficult to discharge the washing wastewater to meet the standard. Using the process method of the present invention, it is firstly desalted by electrodialysis, and then After two-stage anaerobic-aerobic treatment or using an upflow anaerobic sludge bed reactor, the process parameters can be optimized to the greatest extent under limited conditions. After three months of testing, all emission indicators are qualified.

Embodiment 3

[0075] Example 3, a breeding factory in Guangxi adopts mariculture, and the discharge of wastewater is relatively large. In the past, although biological treatment was used, the effect of biological treatment was not very satisfactory because only the high organic matter in the aquaculture wastewater was considered. After adopting the method of the present invention, it is desalinated by electrodialysis and then undergoes two-stage anaerobic-aerobic treatment. The aerobic treatment adopts an intermittent activated sludge device, which can realize the maximum optimization of process parameters under limited conditions. Test 3 Months, the emission indicators are all qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com