Aqueous fluorinated polyurethane curing agent and preparation method thereof

A water-based polyurethane and curing agent technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve many problems, such as the improvement of heat resistance of water-based polyurethane adhesive resins, and achieve water resistance. Excellent, improves heat resistance and water resistance, and improves adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

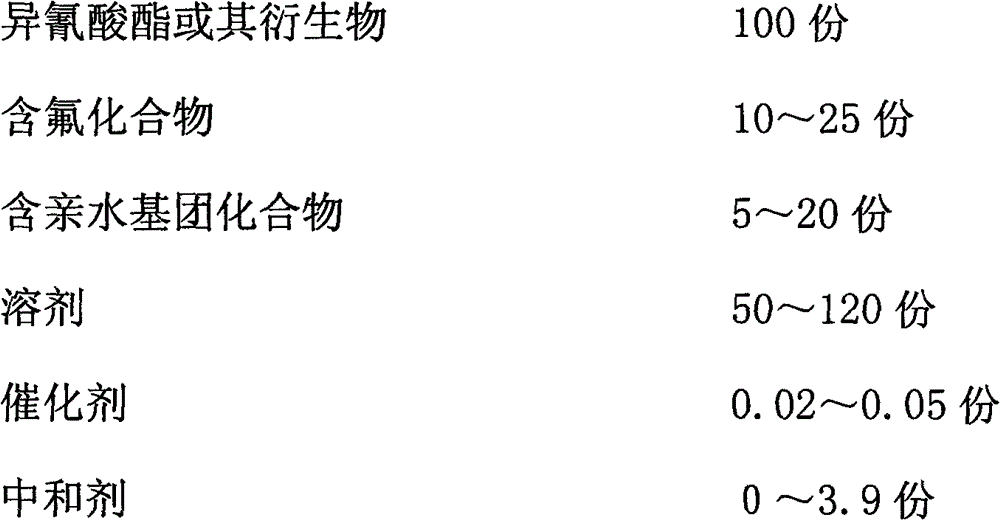

Method used

Image

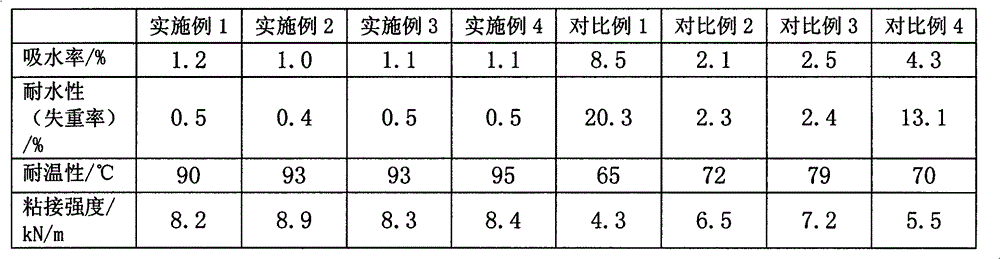

Examples

Embodiment 1

[0038] When equipped with a thermometer and N 2 In a protected four-necked flask, add 10g of fluorine-containing polyether glycol FX3302 (molecular weight 2000), vacuum and dehydrate at 120°C for 2h, cool to 60°C, add 100g HDI biuret, 0.05g dibutyltin dilaurate, 70 React for 3h at ℃, NCO% is 19.4%, then add 5.2g of DMPA, react at 80℃ for 3h, NCO% is 15.8%, add 115g of ethyl acetate to dilute, add 3.9g of triethylamine for neutralization, stir for 0.5h, get the product . Light yellow transparent liquid, viscosity: 150mPa.s, NCO%: 7.8%. 100 parts of the resin of Comparative Example 1 and 5 parts of the curing agent of Example 1 were added. The test data are shown in Table 1.

Embodiment 2

[0040] When equipped with a thermometer and N 2 In a protected four-necked flask, add 24g of fluorine-containing polyether glycol FX3302 (molecular weight 2000), vacuum and dehydrate at 120°C for 2h, cool to 60°C, add 100g HDI biuret, 0.05g dibutyltin dilaurate, 70 React at ℃ for 3h, NCO% is 16.9%, then add 5.2g of DMPA, react at 80℃ for 3h, NCO% is 13.6%, add 115g of ethyl acetate to dilute, add 3.9g of triethylamine to neutralize, stir for 0.5h, then get the product . Light yellow transparent liquid, viscosity: 155mPa.s, NCO%: 7.3%. 100 parts of the resin of Comparative Example 1 and 5 parts of the curing agent of Example 2 are added. The test data are shown in Table 1.

Embodiment 3

[0042] When equipped with a thermometer and N 2 In a protected four-neck flask, add 24g of poly(hexafluoropentamethylenemalonate) glycol (molecular weight 1500), vacuum and dehydrate at 120°C for 2h, then cool to 60°C, add 100g HDI biuret, Dibutyltin dilaurate 0.02g, react at 70℃ for 3h, NCO% is 16.5%, then add 20g polyethylene glycol monobutyl ether (molecular weight 1000), react at 80℃ for 3h, NCO% is 13.7%, add ethyl acetate 115g Dilute and stir for 0.5h to obtain the product. Light yellow transparent liquid, viscosity: 120mPa.s, NCO%: 7.2%. 100 parts of the resin of Comparative Example 1 plus 5 parts of the curing agent of Example 3, and the test data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com