Lac resin hydrosol and preparation method thereof

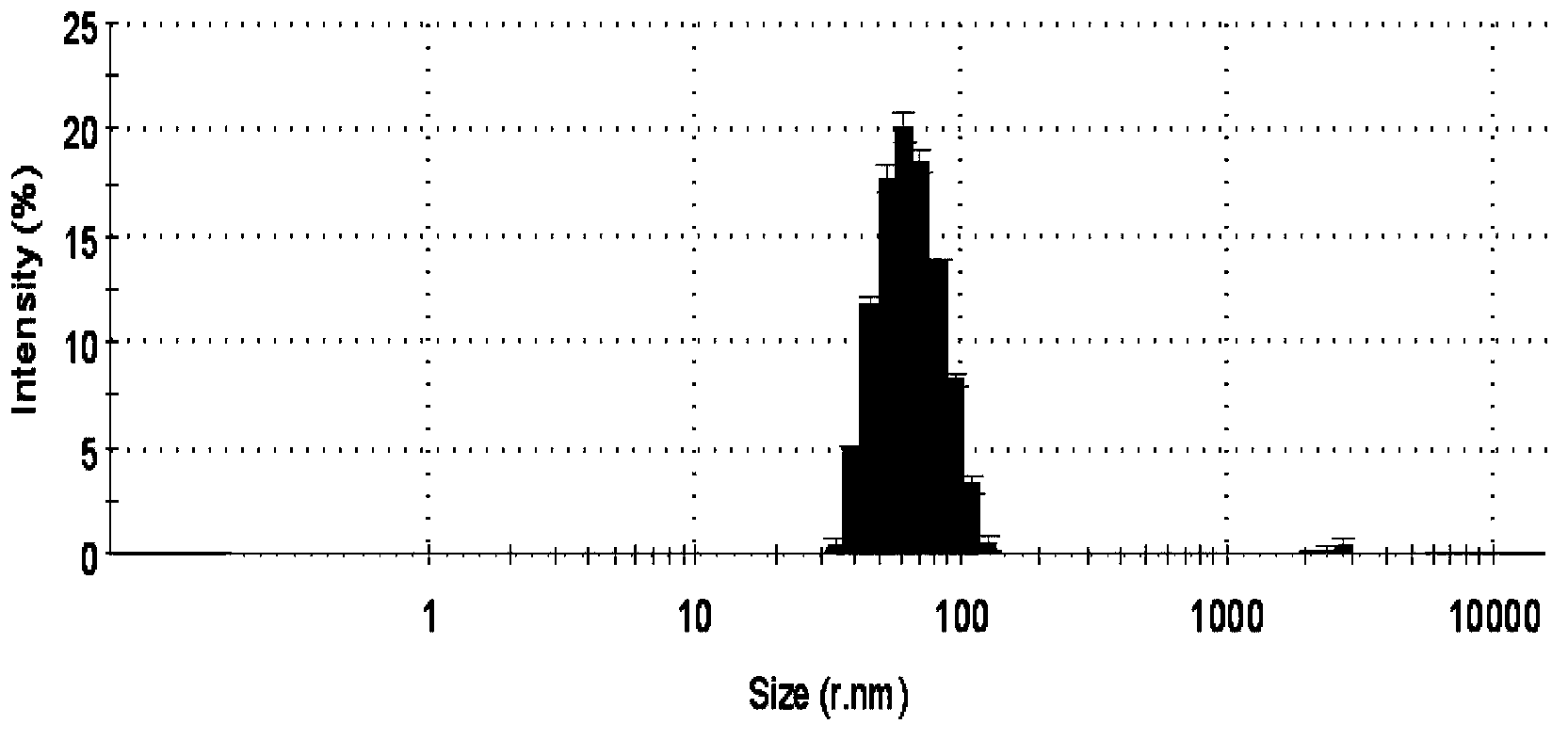

A technology of shellac resin and hydrosol, which is applied in the field of hydrosol and its preparation, can solve the problems of unstable emulsion, cumbersome preparation process, and large particles, and achieves long-term storage and use, short preparation process steps, and particle size. The effect of uniform diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

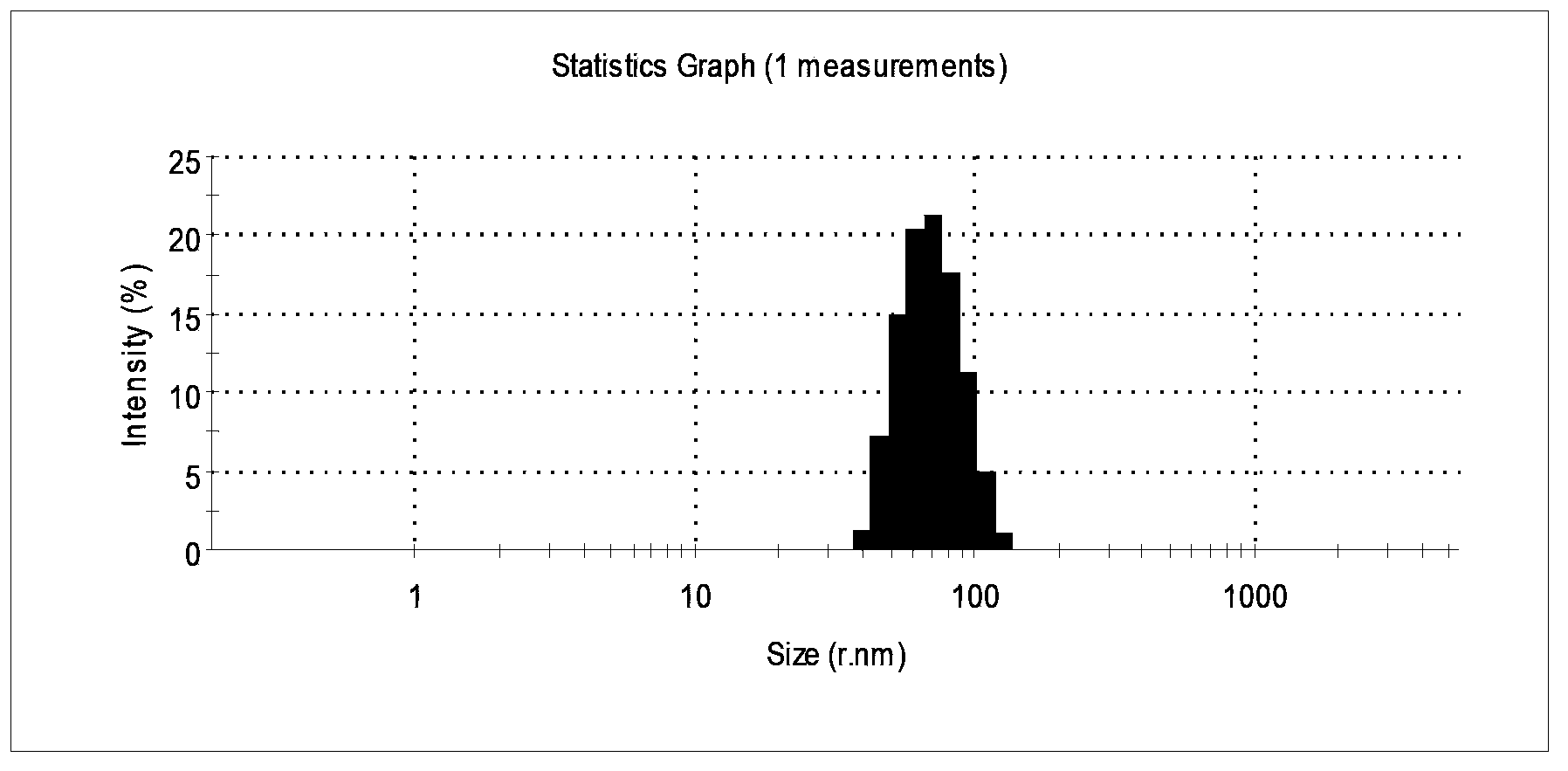

Embodiment 1

[0045] 1. Preparation of lac resin ethanol solution

[0046] 0.3kg shellac resin is added in the absolute ethanol of 9.7kg, stirs and dissolves, makes shellac resin ethanol solution, wherein the mass ratio of shellac resin and absolute ethanol is 3:97, i.e. shellac resin ethanol solution The mass percent concentration of the lac resin is 3%, that is to say, add 3 g of lac resin to 97 g of dehydrated ethanol or add 3 kg of lac resin to 97 kg of dehydrated ethanol.

[0047] 2. Preparation of Lac Wax Resin Collagen Solution

[0048] Put 3L of deionized water in a disperser (Ultra-Turrax T 25 digital disperser, IKA, Germany), and add 1L of the ethanol solution of shellac resin prepared in step 1 to the disperser under stirring. Pump (Baoding Lange Constant Flow Pump Co., Ltd., BT100-1J) to flow out the lac resin ethanol solution prepared in step 1 from the liquid column flow nozzle (Dongguan Boyuan Spray Purification Equipment Co., Ltd.) to form a cylindrical liquid flow and add ...

Embodiment 2

[0054] 1. Preparation of lac resin ethanol solution

[0055] 0.6kg shellac resin is added in the absolute ethanol of 9.4kg, stirs and dissolves, makes shellac resin ethanol solution, wherein the mass ratio of shellac resin and absolute ethanol is 6:94, i.e. shellac resin ethanol solution The mass percent concentration of the lac resin in the medium is 6%, that is to say, 6 g of lac resin is added to 94 g of dehydrated ethanol or 6 kg of lac resin is added to 94 kg of dehydrated ethanol.

[0056] 2. Preparation of lac resin collagen solution

[0057] Put 7L of deionized water in a disperser (Ultra-Turrax T 25 digital disperser, IKA, Germany), and add 1L of the ethanol solution of shellac resin prepared in step 1 to the disperser under stirring. The pump flows out the ethanol solution of shellac resin prepared in step 1 from the liquid column flow nozzle, forms a cylindrical liquid flow and flows into the deionized water of the disperser, and controls the diameter of the liquid...

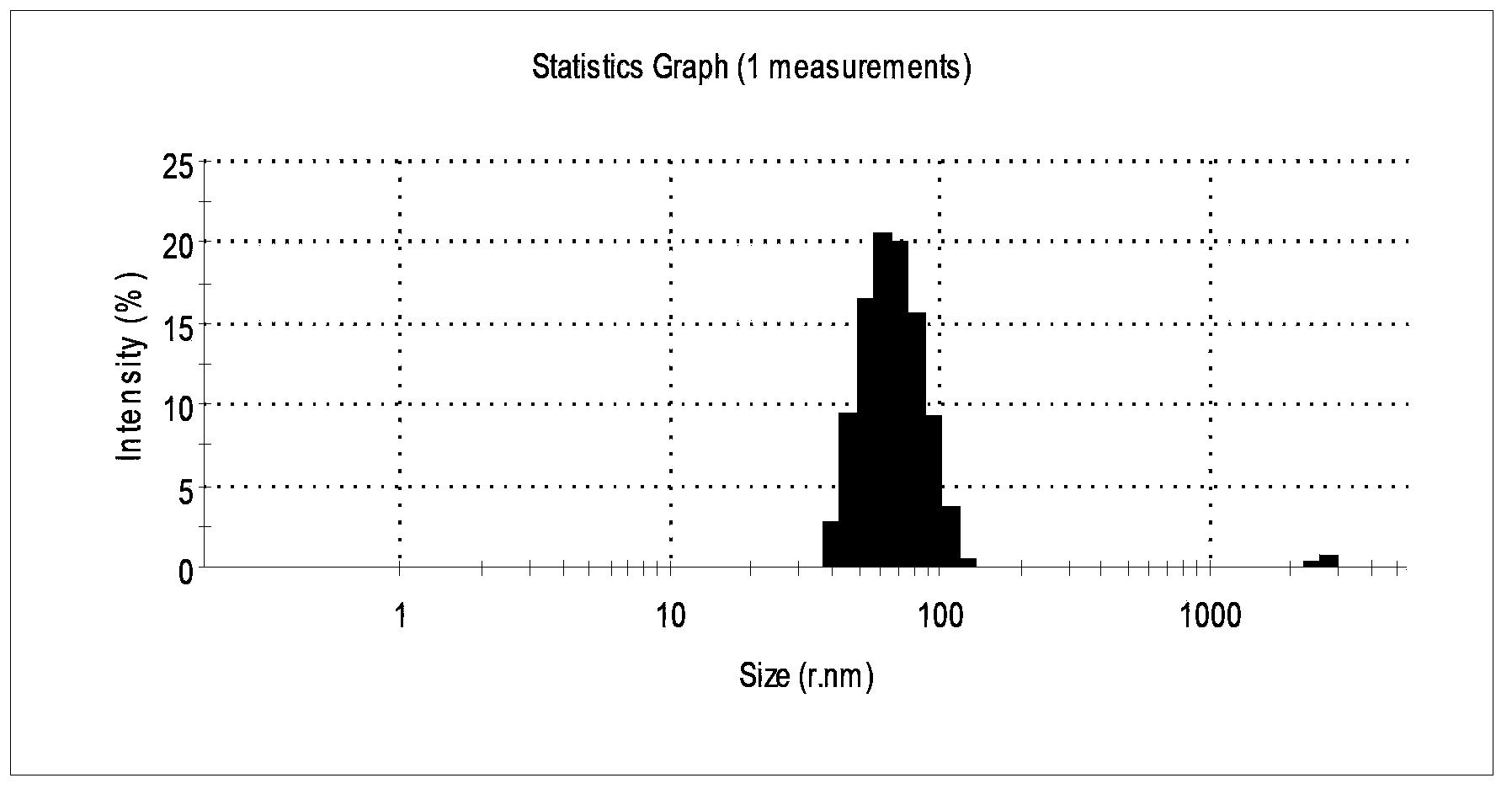

Embodiment 3

[0061] 1. Preparation of lac resin ethanol solution

[0062] 0.7kg shellac resin is added in the dehydrated alcohol of 9.3kg, stirring and dissolving makes shellac resin ethanol solution, wherein the mass ratio of shellac resin and absolute ethanol is 7:93, i.e. shellac resin ethanol solution The mass percent concentration of the shellac resin is 7%, that is to say, add 7g of shellac resin to every 93g of absolute ethanol or add 7kg of shellac resin to 93kg of absolute ethanol.

[0063] 2. Preparation of Lac Wax Resin Collagen Solution

[0064] 10L of deionized water is placed in the disperser, and 1L of the lac resin ethanol solution prepared in step 1 is added to the disperser under agitation, wherein, the lac resin ethanol solution prepared in step 1 is transferred from the liquid column by a constant flow pump Flow nozzle flows out, forms cylindrical liquid flow and flows into the deionized water of dispersing machine, and the diameter of controlling liquid column flow no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com