Weather-proofing anti-scratch ultraviolet cured hard coating composite

A technology of anti-scratch and hard coating, applied in the direction of coating, etc., can solve the problems of insignificant anti-scratch effect, low hardness, insufficient hardness, etc., and achieve obvious wear-resistant and anti-scratch effect, high gloss, and weather resistance good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

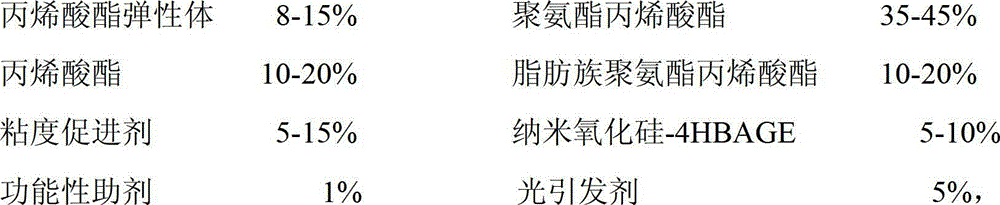

[0023] Example 1, its mass percentage is composed of: 8% acrylate elastomer, 40% urethane acrylate, 15% trifunctional group acrylate, 16% aliphatic urethane acrylate, 10% viscosity accelerator, Nano-silica-4HBAGE is 5%, functional additives are 1%, and photoinitiators are 5%.

example 2

[0024] Example 2, its mass percentage is composed of: 8% acrylate elastomer, 45% urethane acrylate, 15% trifunctional group acrylate, 16% aliphatic urethane acrylate, 5% viscosity accelerator, Nano-silica-4HBAGE is 5%, functional additives are 1%, and photoinitiators are 5%.

example 3

[0025] Example 3, its mass percentage is composed of: 8% acrylate elastomer, 30% urethane acrylate, 20% trifunctional group acrylate, 16% aliphatic urethane acrylate, 15% viscosity accelerator, Nano-silica-4HBAGE is 5%, functional additives are 1%, and photoinitiators are 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com