Anti-graffiti anti-sticking nano coating and preparation method thereof

A nano-coating and anti-graffiti technology, applied in the field of coatings, can solve problems such as high construction requirements, inability to promote use in large areas, difficult maintenance, etc., and achieve strong anti-sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

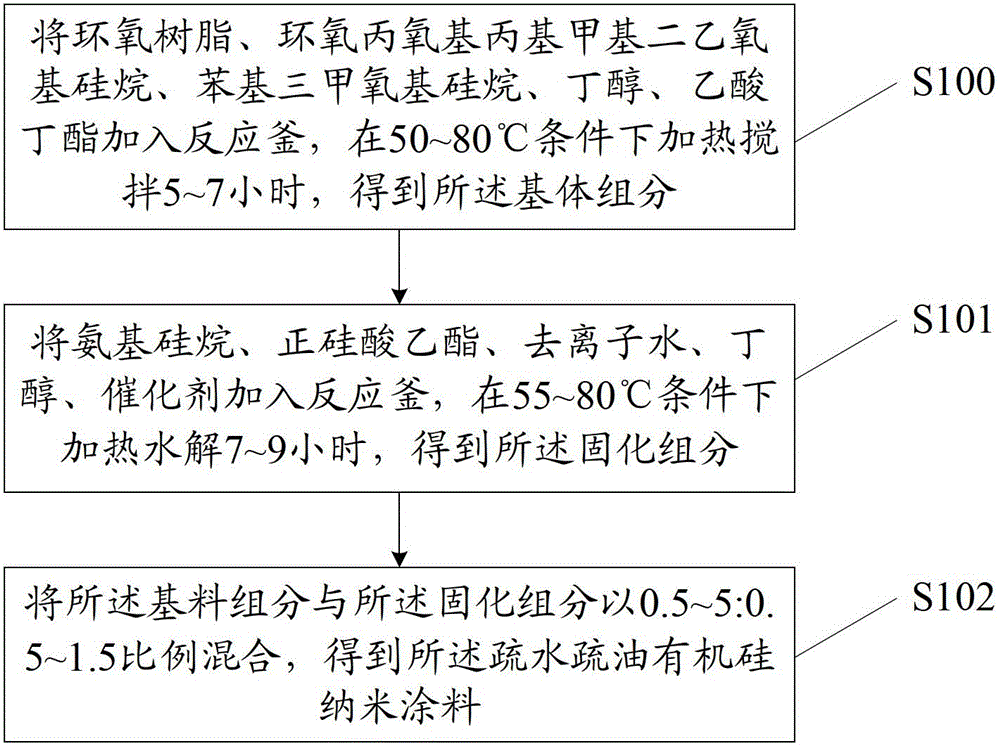

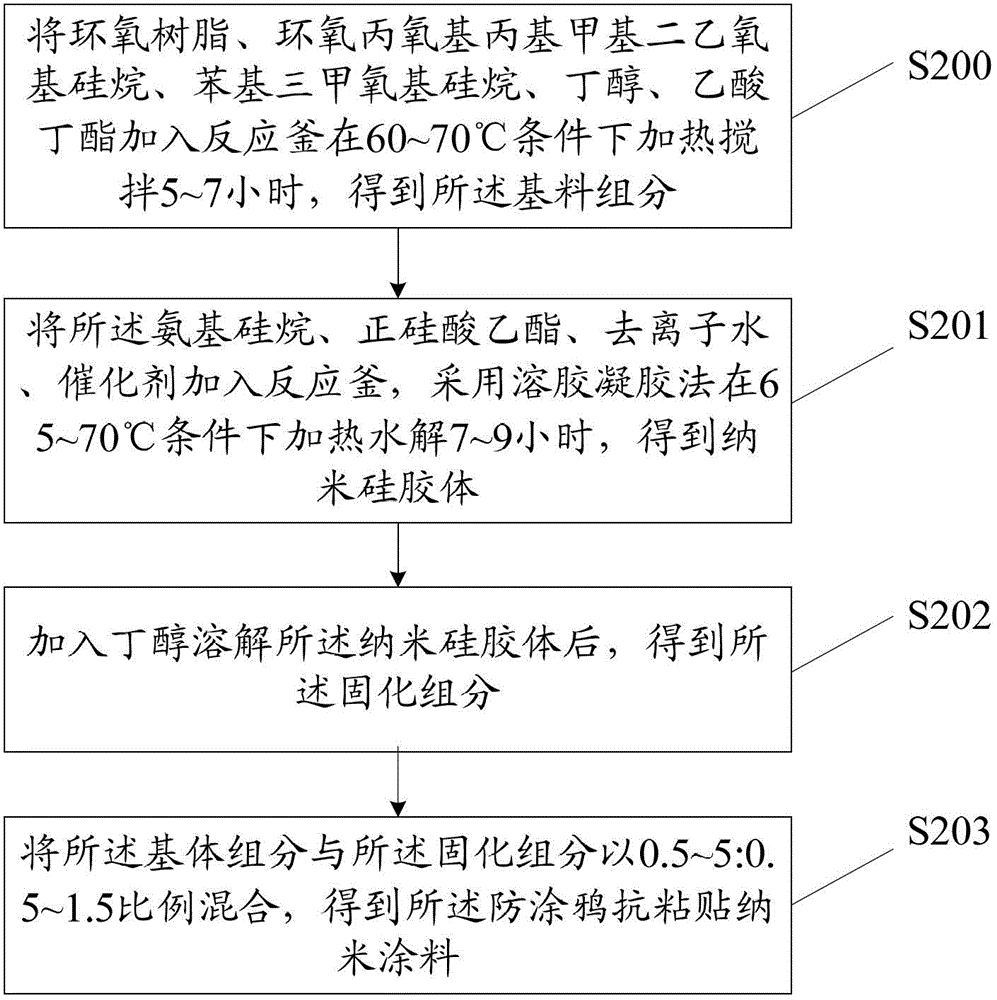

[0066] Correspondingly, as figure 1 As shown, the embodiment of the present invention also provides a preparation method of anti-graffiti anti-sticking nano-coating, including:

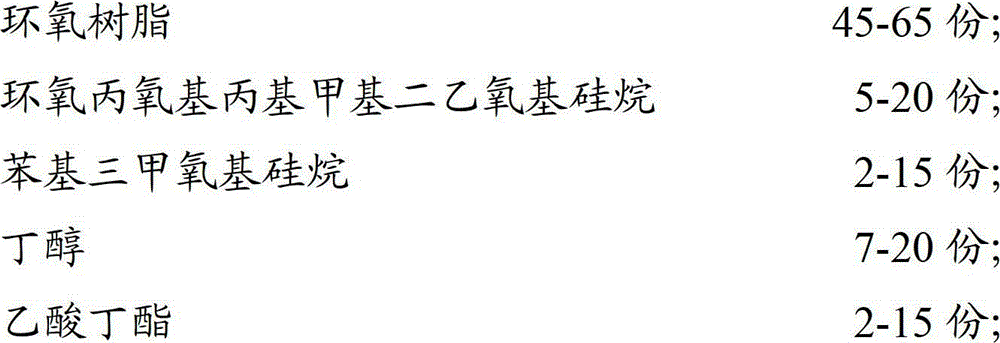

[0067] S100, add epoxy resin, glycidoxypropylmethyldiethoxysilane, phenyltrimethoxysilane, butanol, and butyl acetate into the reaction kettle, heat and stir at 50~80°C for 5~ After 7 hours, the matrix component was obtained.

[0068] Preferably, epoxy resin, glycidoxypropylmethyldiethoxysilane, phenyltrimethoxysilane, butanol, and butyl acetate are put into a reaction vessel and heated and stirred at 60-70°C for about After 6 hours, the matrix component was obtained.

[0069] S101, adding the precursor, tetraethyl orthosilicate, deionized water, butanol, and catalyst into the reaction kettle, heating and hydrolyzing at 55-80° C. for 7-9 hours to obtain the solidified component.

[0070] Preferably, the precursor, tetraethyl orthosilicate, deionized water, butanol, and catalyst are put into a react...

Embodiment 1

[0102] Add 46 parts of bisphenol A type epoxy resin, 18 parts of glycidoxypropylmethyldiethoxysilane, 13 parts of phenyltrimethoxysilane, 10 parts of butanol, and 13 parts of butyl acetate into the reactor Heated and stirred at 60°C for 5 hours to obtain the matrix components; 16 parts of aminomethylsilane, 32 parts of ethyl orthosilicate (type 28), 3 parts of deionized water, and 4 parts of hydrochloric acid were prepared by sol-gel method. Heat and hydrolyze at 60°C for 7.5 hours to obtain nano-silica colloid; dissolve 45 parts of butanol in the nano-silica colloid to obtain a cured component; mix the matrix component with the cured component at a ratio of 1:1 , to obtain anti-graffiti and anti-paste nano coatings.

[0103] The coating of Example 1 is sprayed on the specified base material, and after curing to form a film, the formed paint film is subjected to a performance test, and each performance test result and the following table:

[0104]

Embodiment 2

[0106]Add 50 parts of heteroepoxy epoxy resin, 15 parts of glycidoxypropylmethyldiethoxysilane, 5 parts of phenyltrimethoxysilane, 18 parts of butanol, and 12 parts of butyl acetate into the reactor Heated and stirred at 55°C for 5.5 hours to obtain the matrix component; 20 parts of aminoethylaminopropyl silane, 27 parts of ethyl orthosilicate (type 32), 8 parts of deionized water, and 5 parts of hydrochloric acid were gelled with sol The glue method was heated and hydrolyzed at 70°C for 8 hours to obtain nano-silica colloids; after 40 parts of butanol was dissolved in the nano-silica colloids, a cured component was obtained; the matrix component and the cured component were mixed in 2: Mix in a ratio of 1 to obtain anti-graffiti and anti-stick nano coatings.

[0107] The coating of embodiment 2 is sprayed on the specified base material, and after curing to form a film, the formed paint film is subjected to a performance test, each performance test result and the following tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com