Biodegradable lubricating oil and preparation method thereof

A technology of biodegradation and lubricating oil, which is applied in the direction of lubricating compositions, etc., can solve the problems of poor stability and high cost of biodegradable lubricating oil, and achieve reduced reaction steps, good hydrolytic stability, excellent thermal stability and oxidation stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention further provides the preparation method of above-mentioned biodegradable lubricating oil, comprises the steps:

[0037] Step S01, preparing hindered polyols:

[0038] Adding polyols and long-chain fatty acids with a mass ratio of 0.5:1-2 to an organic solvent, reacting with biological enzymes and at a temperature of 30-90°C for 12-36 hours to obtain hindered polyol esters;

[0039] Step S02, surface-treating the inorganic nanoparticles:

[0040] Mix and stir the inorganic nanoparticles and the surface treatment agent for surface treatment;

[0041] Step S03, mixing:

[0042] The hindered polyol ester, surface-treated inorganic nanoparticles, and diluent are mixed according to the following weight ratio to obtain biodegradable lubricating oil:

[0043] Hindered polyol ester 89%-95%

[0044] Inorganic nanoparticles after surface treatment 1%-10%

[0045] Thinner 1%-10%

[0046] The biological enzyme is selected from one of CCL (A) and CCL (B), ...

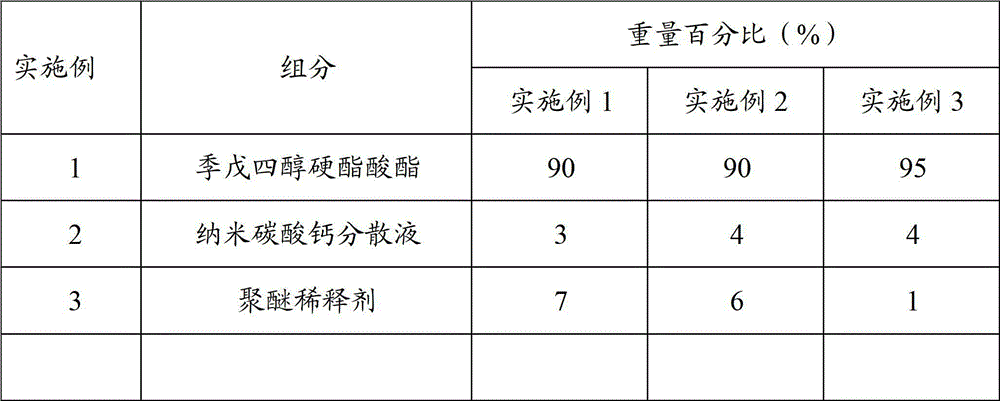

Embodiment 1 3

[0061] In this example, the hindered polyol ester is prepared by bio-enzyme-catalyzed esterification, and the components and weight percentages of the biodegradable lubricating oil are as follows:

[0062] Pentaerythritol ester: 90%~95%;

[0063] Nano tungsten sulfide (WS 2 ): 1%~5%;

[0064] Thinner: 1%~5%;

[0065] The diluent includes at least: polyester, polyether, etc.

[0066] The preparation process is as follows: first, oleic acid, pentaerythritol, and Novo-435 were added to toluene respectively, and reacted at 70-90 degrees Celsius for 24-36 hours. After the reaction, Novo-435 was filtered, and then vacuum distillation was collected to collect 0.01 atmospheric pressure , Components at 160 degrees Celsius. Its specific operation process is as follows:

[0067] 1. Weigh 11.58g, 1.36g of pentaerythritol, and 0.3g of Novo-4350.3g in 10ml of toluene, react at 90°C for 24h, then filter, then distill under reduced pressure, and collect the components at 0.01 atmospheric...

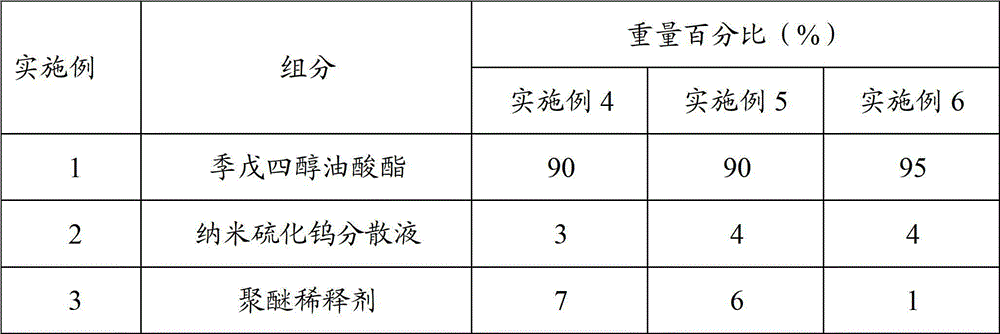

Embodiment 4 6

[0071] In this example, the hindered polyol ester is prepared by bio-enzyme-catalyzed esterification, and the components and weight percentages of the biodegradable lubricating oil are as follows:

[0072] Pentaerythritol stearate: 90%~95%;

[0073] Nano calcium carbonate (CaCO 3 ): 1%~5%;

[0074] Thinner: 1%~5%;

[0075] The diluent includes at least: polyester, polyether, etc.

[0076] The preparation process is as follows: first, oleic acid, pentaerythritol, and Novo-435 were added to toluene respectively, and reacted at 70-90 degrees Celsius for 24-36 hours. After the reaction, Novo-435 was filtered, and then vacuum distillation was collected to collect 0.01 atmospheric pressure , Components at 160 degrees Celsius. Its specific operation process is as follows:

[0077] Weigh 11.66g of stearic acid, 1.36g of pentaerythritol, and 0.31g of Novo-4355 into 10ml of toluene, react at 90°C for 24h, then filter, then distill under reduced pressure, and collect the components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com