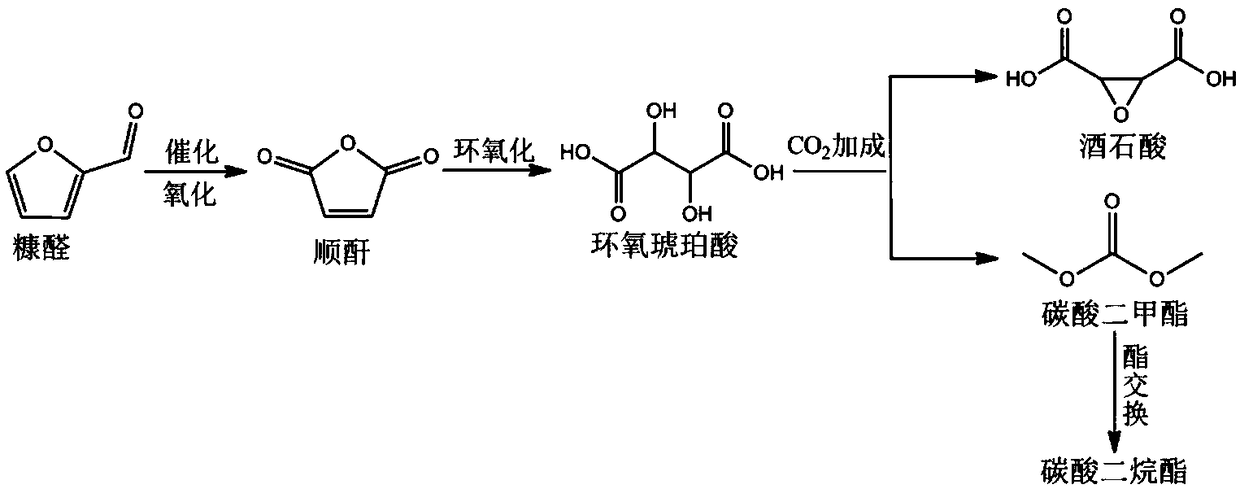

Method for synthesizing dialkyl carbonate from biomass-based furfural

A technology of dialkyl carbonate and biomass, which is applied in the field of preparation of dialkyl carbonate, can solve the problems of high corrosiveness of catalyst equipment, easy deactivation of catalyst, and high operational safety requirements, and achieves significant economic and social benefits, and the synthesis method Scientific environmental protection, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1) Preparation of biomass-based furfural

[0014] Crush 100g of corn cobs to about 1mm, and soak them in 4% sulfuric acid aqueous solution at 120°C for 2 hours. The liquid-solid ratio (V / W) of dilute sulfuric acid to agricultural and forestry wastes is 10:1. The yield of pentose after hydrolysis is 78.67%. Prepare the obtained pentose sugar into a 0.4mol / L solution and put it into a reaction kettle, install a condensation distillation device, control the mass fraction of sulfuric acid to about 20%, the distillation temperature is 190°C, and the distillation time is 5h to obtain a 49% furfural solution.

[0015] 2) Synthesis of maleic anhydride

[0016] The first is the heteropoly acid MoWP / SiO 2 Catalyst preparation. Synthesis of MoWP heteropoly acid: configure 1mol / L ammonium molybdate aqueous solution, then slowly drop phosphoric acid into the ammonium molybdate solution according to the ratio of molybdenum and phosphorus substances to 0.9; weigh the ratio of tungs...

Embodiment 2

[0027] 1) Preparation of biomass-based furfural

[0028] 100g of waste bamboo was crushed to about 1mm, immersed in 5% sulfuric acid aqueous solution at 110°C for 2.5h, and the liquid-solid ratio (V / W) of dilute sulfuric acid to agricultural and forestry waste was 11:1. The yield of pentose after hydrolysis is 70.67%. Prepare the obtained pentose sugar into a 0.6mol / L solution and put it into a reaction kettle, install a condensation distillation device, control the mass fraction of sulfuric acid to about 25%, the distillation temperature is 180°C, and the distillation time is 6h to obtain a 46% furfural solution.

[0029] 2) Synthesis of maleic anhydride

[0030] The first is the heteropoly acid MoWP / SiO 2 Catalyst preparation. Synthesis of MoWP heteropoly acid: configure 1mol / L ammonium molybdate aqueous solution, then slowly add phosphoric acid to the ammonium molybdate solution according to the ratio of molybdenum and phosphorus to 0.85; weigh the ratio of tungsten and ...

Embodiment 3

[0041] 1) Preparation of biomass-based furfural

[0042] Crush 100g of waste wood to about 1 mm, and soak it in 3.5% sulfuric acid aqueous solution at 130°C for 3 hours. The liquid-solid ratio (V / W) of dilute sulfuric acid to agricultural and forestry waste is 13:1. The yield of pentose after hydrolysis is 75.25%. Prepare the obtained pentose sugar into a 0.5mol / L solution and put it into a reaction kettle, install a condensation distillation device, control the mass fraction of sulfuric acid to about 30%, the distillation temperature is 200°C, and the distillation time is 5.5h to obtain a 48.2% furfural solution.

[0043] 2) Synthesis of maleic anhydride

[0044] The first is the heteropoly acid MoWP / SiO 2 Catalyst preparation. Synthesis of MoWP heteropoly acid: configure 1mol / L ammonium molybdate aqueous solution, then slowly drop phosphoric acid into the ammonium molybdate solution according to the ratio of molybdenum and phosphorus substances to 0.9; weigh the ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com